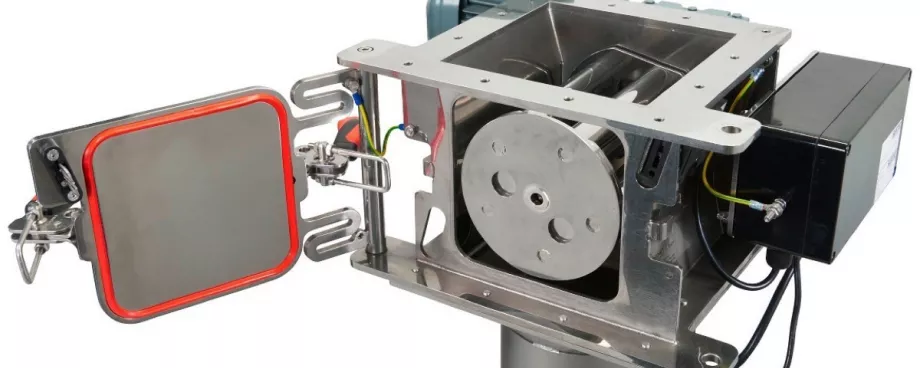

The magnet rotor is composed of 7 strong magnetic bars, equipped with Neodymium-Iron-Boron magnets, each with a diameter of 32 mm, some 40% thicker than regular magnetic bars. Goudsmit claims to be the only company in the market to apply these robust bars in its magnetic separators; this has already proved a huge success with the static version of the cleanflow – the easy clean magnet. The magnetic separator is suitable for free-fall pipes and captures iron as well as AISI 304 and AISI 316 particles as small as 30 µm from, for example, cocoa or milk powder. An additional advantage is the higher capacity powder that the new type of cleanflow magnet can process compared to the 8- or 12-rod magnetic separator. The magnetic extractor is designed to be interchangeable one-to-one with existing rotary cleanflow systems.

Higher Force and Capacity

The magnetic bars in the cleanflow separator filter metal particles and paramagnetic particles out of fatty powders and granular products. The separator is available in 3 sizes, of which the largest model is suitable for product flows of up to 45 m3/h. Goudsmit have extensively tested the magnetic flux density, measuring 10,000 gauss on the contact surface of the bars. The maximum working and product temperature is 140°C, the minimum and maximum ambient temperature: -20°C to 40°C. The disadvantage of greasy (milk) powder is that this product does not flow well; this is why the magnetic bars rotate in the product flow. This prevents bridge formation and material accumulation and ensures optimal magnetic contact to effectively capture metal contamination. In short: with this new superstrong magnetic separator, customers can achieve a high degree of separation and a clean end product.

Quick and easy Cleaning

During the manual cleaning cycle, the operator removes the rotor from the housing and pulls the magnetic bars out of the extractor, after which the metal particles are loosened and can be safely disposed of. Goudsmit have also developed a special cleaner system, which allows to clean the extractor easily and hygienically.

■