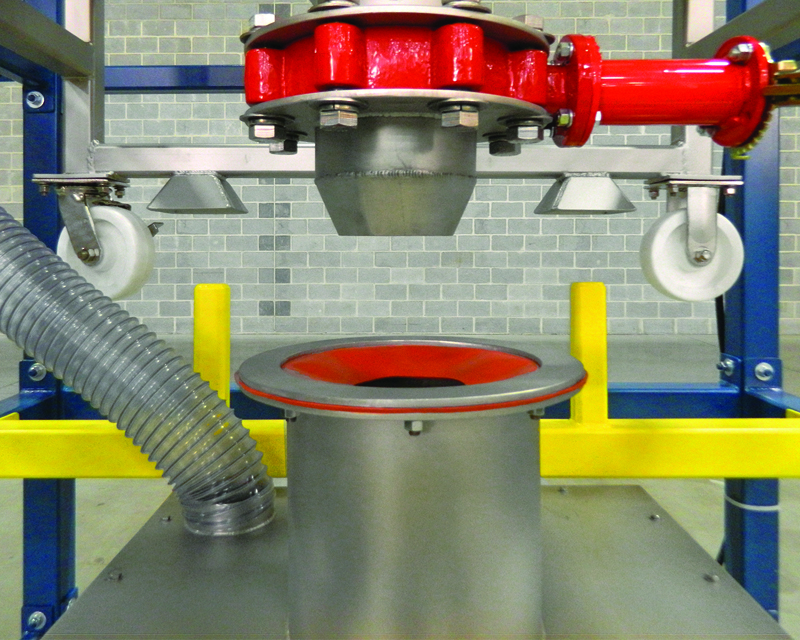

When lowered into position, the tapered outlet of the IBC’s butterfly discharge valve mates with a gasketed receiving ring on the lid of a surge hopper, allowing opening of the valve and discharging of material with no dusting.

The surge hopper is available with an integral flexible screw conveyor, tubular cable conveyor or pneumatic conveying system also produced by the company.The purpose-built stainless steel IBC hopper frame measures 914 mm square by 965 mm high and includes two swivel and two rigid castors with brakes. Quick-release clamps secure the hinged hopper lid during transport and discharge of material.

A port on the lid of the surge hopper is vented to a BAG-VAC™ dust collector that puts the sealed system under negative pressure, preventing displaced air and dust from entering the plant atmosphere.All material contact surfaces of the system are of stainless steel with the exception of the flexible screw conveyor’s polymer outer tube.

The company also manufactures bulk bag dischargers, pneumatic conveyors, flexible screw conveyors, tubular cable conveyors, bulk bag conditioners, bulk bag fillers, bag dump stations, drum/box/container tippers, weigh batching and blending systems, and engineered plant-wide bulk handling systems with automated controls. ■