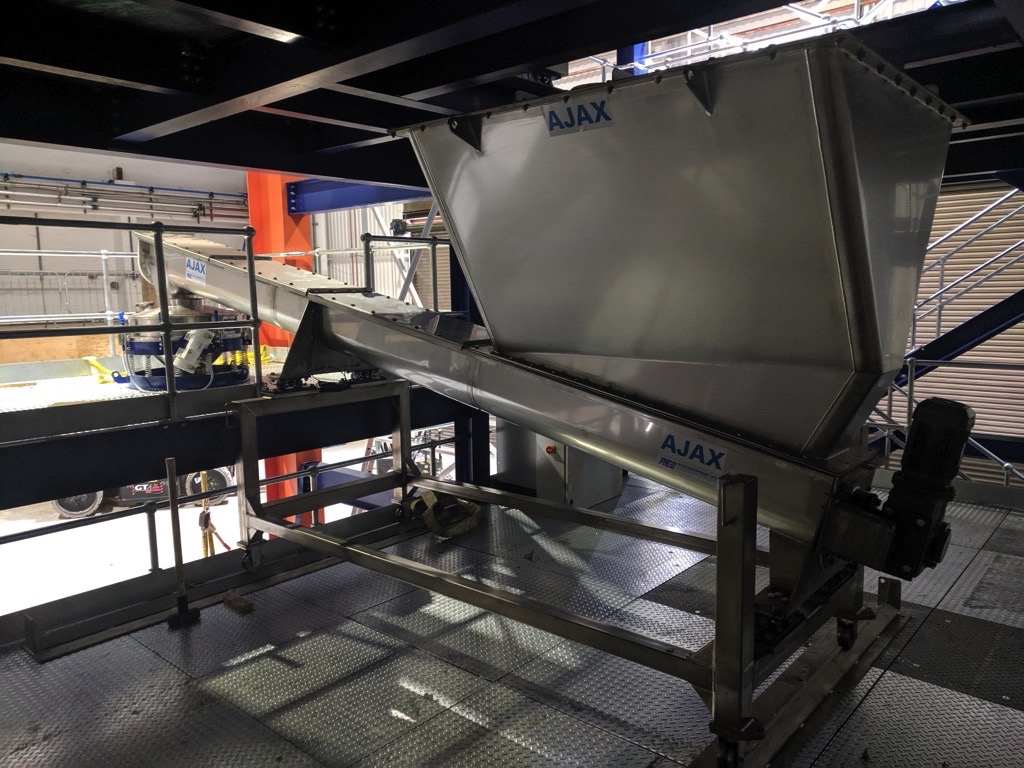

The single screw feeders, inclined at 12 degrees, feature full flights with a variable pitch which ensure a consistent flow of material to a sieve and sack filler. Using a powder sample from the customer, Ajax conducted shear strength measurements as well as wall friction and bulk density tests. The resulting data was used to determine the hopper’s shape, slope and outlet size, as well as the interfaced screw’s size, geometry and speed.The integrated hopper and screw feeders receive batches of the powder, controlling the feed into a sieving process prior to bagging. Each set of equipment sits on a frame, including load cells to monitor the hopper load, which itself is mounted on rails for plant configuration flexibility.Commenting Mark BennettDoy, Works Engineer at Pathway Intermediates said “We approached Ajax to supply a pair of augers and hoppers to receive bulk discharge of powder products from our mixing plant and to meter this through a sieving system to collection hoppers. There were a number of iterations from the initial design brief through to examination of the final build. As we had experienced previously, Ajax’s support at every stage from initial design through to after sales support was exemplary; I can only thank them for their help.”“Our powder testing showed the material required a vee hopper with steep walls and a large outlet size for flow. However, careful screw design was needed to ensure the correct extraction over the extent of the large hopper outlet,” says Eddie McGee, managing director, Ajax Equipment. ■