Mobile Ship Loading (Continued)

(continued)

Minelco has long been an important supplier of olivine, though without previously having a raw-material source of its own. The Board of LKAB decided in 2004 to invest in the Seqi olivine deposit in Greenland and mining began in August 2005. The European steel industry is a self-evident market for olivine, which is an important additive in LKAB’s blast furnace pellets.

A small ceremony was held on 11 August, 2005 to celebrate the start-up of the project involving Greenland’s Prime Minister Hans Enoksen and LKAB’s President, Martin Ivert.

The first vessel with olivine sailed from Greenland on December 2nd 2005, bound for Amsterdam.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8808-b-w-mechanical-handling.htm" target="blank">https://edir.bulk-online.com/profile...l-handling.htm

href="https://edir.bulk-online.com/profile/8058-aumund-fördertechnik.htm" target="blank">https://edir.bulk-online.com/profile...dertechnik.htm

Photo:

Working during Jetty Construction

Attachments

■

Mobile Ship Loading (Continued)

(continued)

From the crusher stockpile the Olivine is taken by loading shovel to the Shiploader utilising a Samson 1600 series mobile feeder to control the loading rate to a design capacity of 2,000 tons per hour.

The jetty is simply constructed with in-filled rock; fenders and mooring dolphins are provided for berthing vessels typically up to Handymax size (50,000 DWT).

This is an excellent example of the application of the professional mobile Shiploader in a location where fixed or rail mounted equipment would be entirely inappropriate.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8808-b-w-mechanical-handling.htm" target="blank">https://edir.bulk-online.com/profile...l-handling.htm

href="https://edir.bulk-online.com/profile/8058-aumund-fördertechnik.htm" target="blank">https://edir.bulk-online.com/profile...dertechnik.htm

Photo:

Samson 1600 Series Mobile Feeder

Attachments

■

Mobile Ship Loading (Continued)

(continued)

The mobile solution eliminates the need for permanent port infrastructure or even any concrete quay surface or foundations and offers the operator the flexibility to establish an export facility with minimum cost and fast track availability.

In the early phase of the export operation a simple finger jetty was established and stationary mobile equipment used to load directly over the ships side.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8808-b-w-mechanical-handling.htm" target="blank">https://edir.bulk-online.com/profile...l-handling.htm

href="https://edir.bulk-online.com/profile/8058-aumund-fördertechnik.htm" target="blank">https://edir.bulk-online.com/profile...dertechnik.htm

Photo:

Crushing and Screening Station

Attachments

■

Mobile Ship Loading (Continued)

(continued)

With operating temperatures down to below minus 30 degrees in such an exposed position the wind chill factor is extreme and required special adaptation of the standard B&W specifications to achieve the performance and availability required.

During summer the temperature may reach a sweltering plus 10 degrees but for most of the year it is sub-zero creating problems not only for the equipment but with frozen stockpiles creating material flow problems.

B&W were able to deliver the performance and reliability demanded in this extremely harsh working environment

Whilst at present the Olivine is transported from the local stockpile by loading shovel in the future the B&W design “Link Conveyor” may be employed to transfer the material more economically over larger distances.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8808-b-w-mechanical-handling.htm" target="blank">https://edir.bulk-online.com/profile...l-handling.htm

href="https://edir.bulk-online.com/profile/8058-aumund-fördertechnik.htm" target="blank">https://edir.bulk-online.com/profile...dertechnik.htm

Photo:

Extreme Working Conditions

Attachments

■

Mobile Ship Loading (Continued)

(continued)

Remaining in the near arctic another recent delivery in the north of Russia the largest ever B&W Stormajor radial boom mobile loader delivers Gabbros direct from both loading shovels and tipping trucks into large river barges, typically around 5,000 tons and at a rate of 700 t.p.h.

In this operation the equipment is located on a large lake close to the small town of Sheleki which is between St. Petersburg and Murmansk.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8808-b-w-mechanical-handling.htm" target="blank">https://edir.bulk-online.com/profile...l-handling.htm

href="https://edir.bulk-online.com/profile/8058-aumund-fördertechnik.htm" target="blank">https://edir.bulk-online.com/profile...dertechnik.htm

Photo:

Gabbros Barge Loading in Russia

Attachments

■

Mobile Ship Loading (Continued)

(continued)

The Gabbros is crushed down on site to various grades suitable for use as aggregate in concrete or road building and shipped primarily to both St. Petersburg and Moscow where hard stone is not readily available locally.

With its cantilevered radial outloading boom the Stormajor is ideal for loading barges from a lake or river berth using its long outreach to span out to the barge moored to dolphins just off the shore line.

The Stormajor comprises a Samson surface feeder unit plus a radial and luffing outloading boom both mounted to a common mobile chassis as a single autonomous unit.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8808-b-w-mechanical-handling.htm" target="blank">https://edir.bulk-online.com/profile...l-handling.htm

href="https://edir.bulk-online.com/profile/8058-aumund-fördertechnik.htm" target="blank">https://edir.bulk-online.com/profile...dertechnik.htm

Photo:

Integral Samson Feeder

Attachments

■

Mobile Ship Loading (Continued)

(continued)

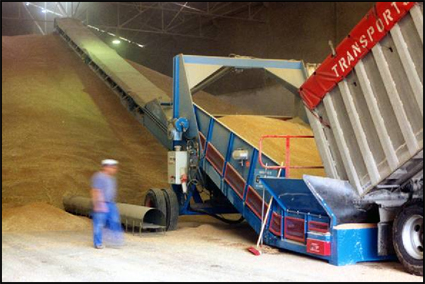

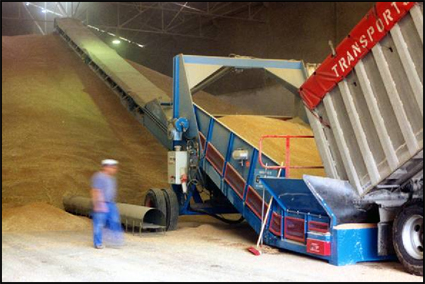

The Samson feeder will receive most bulk materials direct from tipping trucks, dump trucks and/or loading shovels.

For example the unit as illustrated was supplied in 1993 to La Dauphinoise in central France receives cereals from tipping trucks for loading to storage, a second machine of almost identical specification was supplied last year (2006) for the same duty.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8808-b-w-mechanical-handling.htm" target="blank">https://edir.bulk-online.com/profile...l-handling.htm

href="https://edir.bulk-online.com/profile/8058-aumund-fördertechnik.htm" target="blank">https://edir.bulk-online.com/profile...dertechnik.htm

Photo:

Stormajor handling grain

Attachments

■

Mobile Ship Loading (Continued)

(continued)

Over the last 25 years the Stormajor has evolved into a multi-purpose loading tool equally suited to small storage operations through to major installations handling very heavy and abrasive materials.

The latest evolution of the design is illustrated here at the port of Düsseldorf handling iron ore transhipped from barges to railcars.

The iron ore is transhipped at deep water ports and loaded to small Rhine barges for inland haulage to distribution centres such as at Neuss Düsseldorf.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8808-b-w-mechanical-handling.htm" target="blank">https://edir.bulk-online.com/profile...l-handling.htm

href="https://edir.bulk-online.com/profile/8058-aumund-fördertechnik.htm" target="blank">https://edir.bulk-online.com/profile...dertechnik.htm

Photo:

Iron Ore Discharge in Düsseldorf

Attachments

■

Mobile Ship Loading (Continued)

(continued)

At Neuss Düsseldorf the iron ore is taken by grab crane direct from the barges and transferred to the extended Stormajor receiving hopper.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8808-b-w-mechanical-handling.htm" target="blank">https://edir.bulk-online.com/profile...l-handling.htm

href="https://edir.bulk-online.com/profile/8058-aumund-fördertechnik.htm" target="blank">https://edir.bulk-online.com/profile...dertechnik.htm

Photo:

Stormajor receives direct from grab

Attachments

■

Mobile Ship Loading (Continued)

(continued)

Using the Stormajor radial outloading boom fitted with a rotating trimming chute the iron ore is transferred direct to railcars.

This unit in Düsseldorf has two unique features; it is the first Stormajor designed for receiving from grab crane and also it is the first Stormajor to be supplied with a weighing system mounted to the outloading boom to check the weight of material loaded to each railcar, a difficult task on mobile equipment in particular. Railcar overload is a real problem with heavy materials such as Iron Ore and can be very expensive when the excess material must be manually recovered.

Comprising a single weigh idler mounted mid way of the radial boom plus an encoder to measure the belt speed and an inclinometer to measure the machine working angle all linked to an integrator circuit the weighting system achieves an overall accuracy of plus or minus 1.5 %.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8808-b-w-mechanical-handling.htm" target="blank">https://edir.bulk-online.com/profile...l-handling.htm

href="https://edir.bulk-online.com/profile/8058-aumund-fördertechnik.htm" target="blank">https://edir.bulk-online.com/profile...dertechnik.htm

Photo:

Iron Ore loading to Railcars

Attachments

■

Mobile Ship Loading (Continued)

(continued)

Remaining with iron ore the Stormajor solution has been chosen by Salgoacar Mining Industries (SMI) of Goa (India) to load locally mined ore into barges to be taken down river to a deep sea transhipment facility moored offshore.

Illustrated during commissioning; one of six Stormajor units supplied to SMI incorporating an extended Samson feeder unit to receive from three tipping trucks simultaneously to achieve the design loading rate of 1,250 tonnes per hour.

In addition to the Stormajor units SMI have also taken delivery of two B&W mobile Shiploaders designed for loading direct to Panamax sized vessels at a spot loading rate of 2,000 tonnes per hour.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8808-b-w-mechanical-handling.htm" target="blank">https://edir.bulk-online.com/profile...l-handling.htm

href="https://edir.bulk-online.com/profile/8058-aumund-fördertechnik.htm" target="blank">https://edir.bulk-online.com/profile...dertechnik.htm

Photo:

Stormajor barge loaders in India

Attachments

■

Mobile Ship Loading (Continued)

(continued)

For 2006/7 delivery new orders for the Stormajor are in progress for Group CICE in Mexico handling Fertilisers and Dolphin Energy of Qatar handling Sulphur.

Illustrated here the Stormajor cantilevered radial boom supported entirely from above providing maximum outreach and the ability to store material with low repose angle.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8808-b-w-mechanical-handling.htm" target="blank">https://edir.bulk-online.com/profile...l-handling.htm

href="https://edir.bulk-online.com/profile/8058-aumund-fördertechnik.htm" target="blank">https://edir.bulk-online.com/profile...dertechnik.htm

Photo:

Dolphin Energy of Qatar

Attachments

■

Mobile Ship Loading (Continued)

(continued)

Since the whole length of the radial boom overhangs the axle beam there is no risk free flowing materials such as grain will run back and engulf the wheel.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8808-b-w-mechanical-handling.htm" target="blank">https://edir.bulk-online.com/profile...l-handling.htm

href="https://edir.bulk-online.com/profile/8058-aumund-fördertechnik.htm" target="blank">https://edir.bulk-online.com/profile...dertechnik.htm

Photo:

Stormajor Handling Sulphur

Attachments

■

Mobile Ship Loading (Continued)

(continued)

In the early days the mobile Shiploader tended to be just a simple mobile conveyor used for loading small coasters in river berths at relatively load handling rates.

Over the intervening years the market has changed and the mobile solution has steadily become the preferred option in many locations from the artic to the equator.

In the 25 years since the first B&W mobile Shiploader was delivered to the port of Kings Lynn in England around 80 units of varying sizes from 15 metres to 55 metres in length with handling rates from 300 up to 2,000 t.p.h. have been produced for ports and terminals worldwide.

Important new orders are in progress for Yen Bai Cement in Vietnam handling limestone and BetonCem in Italy handling cement clinker.

For SAQR Port Authority in the United Arab Emirates two very large Shiploaders of boom length 50 metres are presently in progress.

These enormous machines are fitted with twin Samson feeder units enabling two trucks to be discharged simultaneously to achieve a spot loading rate of 2,000 t.p.h.

Plus… powered travel systems and a telescopic and rotating trimming spout system for vessel trimming are provided to further speed the loading operation by reducing the trimming time.

An onboard diesel gen-set is provided to power the complete equipment making the machines fully autonomous independent of shoreside power supplies.

A very recent new order for the Goldfields Cerro Corona project in Peru, comprising an integral Samson surface feeder plus Mobile Shiploader of 35 metres length to load typically to vessels of 25,000 DWT at a peak loading rate of 900 tonnes per hour handling both copper and gold ores.

Both the machines for SAQR Port and Goldfields are to be supplied with both in-line and parallel powered travel equipment allowing the Shiploader to be travelled along the vessel to minimise trimming delays.

These new projects represent the pinnacle of the mobile Shiploader development (thus far…) raising the benchmark for mobile solutions as a realistic but flexible alternative to fixed port installations.

However, this is not the end of the B&W story since in June 2002 the company was acquired by the Aumund Group of Germany, a highly respected and substantial international organisation incorporating the Aumund Fördertechnik Company plus Schade Lagertechnik also of Germany.

The integration of B&W into the Aumund Group has opened opportunities to develop the B&W surface mounting and mobile handling solutions worldwide.

With daughter companies or representative offices in China, Hong Kong, India, Brazil, Switzerland, Poland and the USA plus manufacturing companies in Germany and the UK the Aumund Group are very well placed to deliver first class service close to their clients.

For more information, please visit:

https://edir.bulk-online.com/profile...l-handling.htm

https://edir.bulk-online.com/profile...dertechnik.htm ■

Mobile Ship Loading (Continued)

(continued)

In today’s rapidly changing international market the ability to react quickly to market volatility and take advantage of short-term market positions is essential if operators are to maximise profitability and return on capital invested.

The Mobile Solution offer the performance both in loading rates and environmental qualities of a fixed installation with the added bonus of complete flexibility and ease of operation on existing berths without the need for dedicated port infrastructure or expensive permanent civil works.

The Truck-to-Ship concept, possible by virtue of the Samson surface feeder, opens new possibilities for existing ports eliminating the need for on port storage and the associated double handling.

This flexible concept simplifies investment decisions allowing the port operator or shipper to take advantage of smaller but potentially lucrative cargo volumes and short term contracts that would certainly not be viable with the high investment and long lead times associated with a conventional fixed installation.

Furthermore for large fixed installations the local permitting process and inevitable environmental impact study requirements may often be waived for mobile plant not only simplifying the process of bring a new facility into the port but speeding the effective project lead time from identifying the potential bulk export opportunity to loading the first vessel.

Mobile solutions are not tied to one berth, one harbour or even one Port and may be easily moved should circumstances demand or may even be re-sold if a contract is terminated. A strong second-hand market has developed around this concept with several companies specialising in the resale market…

So in conclusion after 25 years of development now combined with the benefit of integration to a substantial and respected international group the B&W mobile and surface mounted solution for ports and terminals has reached maturity.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8808-b-w-mechanical-handling.htm" target="blank">https://edir.bulk-online.com/profile...l-handling.htm

href="https://edir.bulk-online.com/profile/8058-aumund-fördertechnik.htm" target="blank">https://edir.bulk-online.com/profile...dertechnik.htm

Photo:

Mobile Shiploader – Truck to Ship

Attachments

■

Mobile Ship Loading

Mobile Ship Loading Solutions – 2007

Important New Dry Bulk Cargo Port Handling Projects for 2007

B&W Mechanical Handling Ltd. of the UK (part of the Aumund Group) has recently commissioned an important new Mobile Shiploader in Greenland for the export of Olivine rock at Fiskefjord, which lies about 70 km north of Nuuk, the capital.

Olivine is found in the volcanic rocks of Greenland where there are substantial deposits and is an important mineral used in steel production mainly as a refractory raw material and slag conditioner.

This new facility is operated by MT Højgaard of Denmark under contract on behalf of Minelco (part of the LKAB group headquartered in Sweden) and includes a mining operation plus crushing and screening station located close to the new deep water jetty with a planned annual output of 2 million tons.

For more information, please visit:

https://edir.bulk-online.com/profile...l-handling.htm

https://edir.bulk-online.com/profile...dertechnik.htm

Photo:

Exporting Olivine from Greenland

Attachments

aumund_1 (JPG)

■