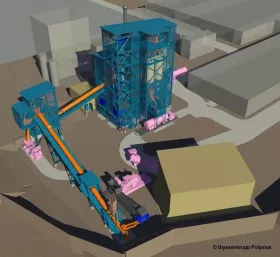

Luc Rudowski, Head of Innovation at thyssenkrupp Polysius: "The composite cement to be produced with the newly developed meca-clay only emits around 350 kilograms of CO2 per tonne of cement. Compared to average conventional cement production, the CO2 footprint can be reduced by around 42 percent."

For years, cement manufacturers have been trying to reduce the so-called clinker factor - the proportion of clinker in cement - by adding Supplementary Cementitious Materials. Based on the joint research results in the production of activated clays and the excellent performance achieved in both cement mortar and concrete formulations, SCHWENK Zement and thyssenkrupp Polysius are convinced of the superiority of the new process over conventional clay calcination process. A further advantage: in contrast to the conventional combustion process for clay calcination, the new process does not require any fossil fuels to activate the clay and therefore causes no emissions of air pollutants.

■