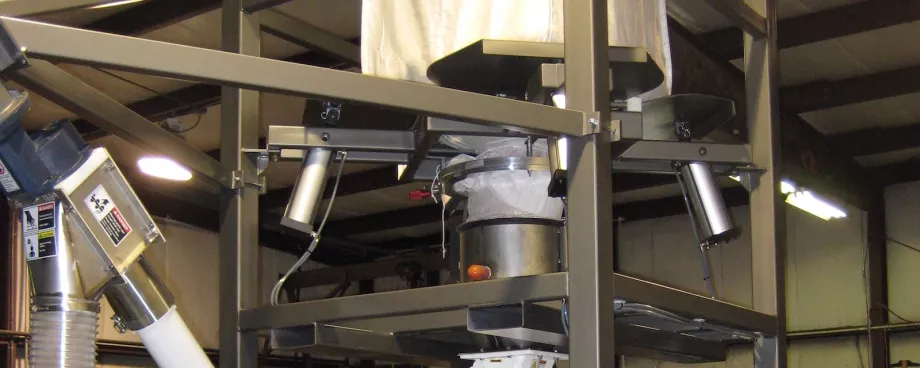

The comprehensive bulk bag unloading system for premixed food ingredients incorporates the mechanical structure which houses and supports the bag discharge, material weighing, dispensing (flexible screw conveyor) and control panel components.

Included Components

Mechanical components are provided to unload the bulk bag, accurately weigh the desired amount of material as set for a batch by the operator, and then dispense the batch of material into a container for production use. In addition, Sterling is a UL listed control panel builder and provides the VFD panel and equipment along with a system control panel. Based upon an upfront review of customer goals the system was custom designed for efficient and accurate operation to meet the needs of the customers’ production system.

Mechanical components are provided to unload the bulk bag, accurately weigh the desired amount of material as set for a batch by the operator, and then dispense the batch of material into a container for production use. In addition, Sterling is a UL listed control panel builder and provides the VFD panel and equipment along with a system control panel. Based upon an upfront review of customer goals the system was custom designed for efficient and accurate operation to meet the needs of the customers’ production system.

Typical Operation

The operation of the bulk bag unloading and weighing system is easy for the operator to use. After hanging a full bulk bag in place within the upper part of the support structure and routing the bag spout through the iris valve and into the bag clamp, the operator will open the bag spout to start the flow of the material into the bulk bag unloader. The operator will next turn on the main power to the VFD and Control panels and disengage the emergency stop. With control set for Auto, the operator then sets the Target weight, Fast Cutoff and Slow Cutoff setpoints, as well as the Slow Fill speed. At this point the operator will press the Start Batch pushbutton to begin the automated process of bulk bag discharge, material weighing and dispensing. ■