Re: Chain Conveyor Tension

Dear John

Thanks for your attention.

In this system when the conveyor push the skids, the chain strand between pusher dog and drive sprocket is under tension. So the spring is located at the end of conveyor don't sense this tension. Moreover i think the chain strand at the rerun and end of conveyor loose.

I think the best way is used tension at the drive station. But given that at this position we have bearing block, drive sprocket and the other part i don't know how i can do that. So if you have a suggestion please help me.

Best Regards

Hadi Marvi ■

Chain Conveyor For Pulling Cartd

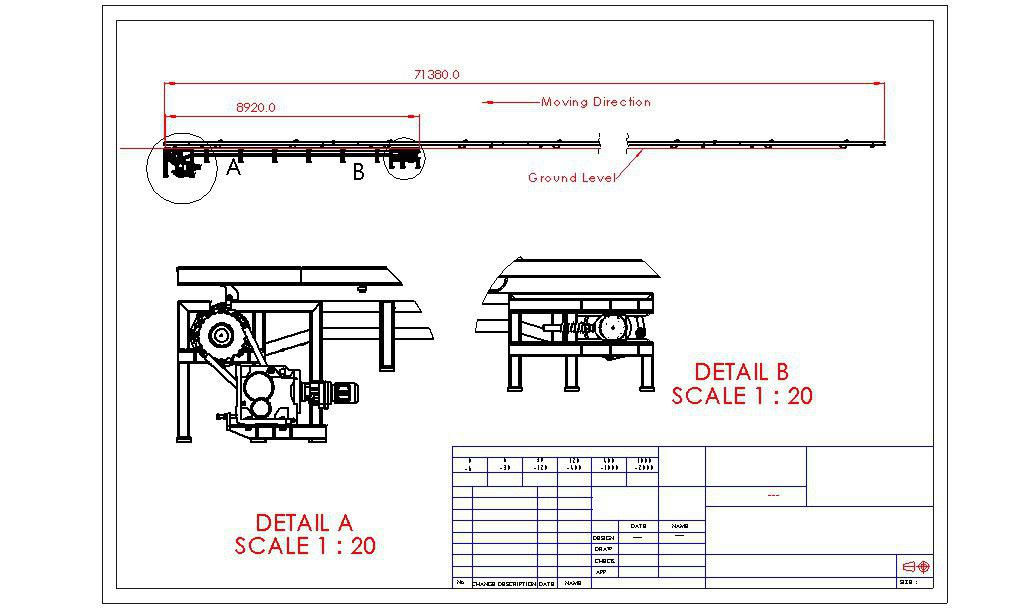

I design a chain conveyor to pull 12 carts that linked together. the conveyor installed at the end of line and pull all of the linked carts. The schematic of this as attached. I consider a tension at the end of conveyor but it didn't worked correctly. Now i want to know how i can solve the problem. I think that the position of tension is not correct. The chain conveyor used in the assembly line. the worker installed parts on the cart.

Thanks & Regards

Hadi Marvi

You need to have all the carts traveling on a floor rail arrangement. The purpose of the chain CONVEYOR needs to have dogs/ locks mounted on the chain to engage with the carts at a similar pitch. The chain CONVEYOR should be profiled like a caterpillar drive and its length limited to the pitch of the carts. As one cart leaves the caterpillar chain CONVEYOR the next engages. This arrangement should solve your problem. ■

Tensile Force Basics

Examine the distribution of tension within an endless loop and consider that the skid engagement is a step input: because it is.

Drive power is introduced through the sprocket. To accommodate a step input the sprocket, and drive, would have to relax at engagement. This is impractical, to say the least. The drive tension would have to reduce by the same amount as the step input imparts ie stall will most probably result. You need a tension control which does not affect the drive. Full stop: excuse the pun. Revert to my earlier comment and introduce travel within the tail shaft assembly. ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Re: Chain Conveyor Tension

Dear Mr. Karrimore

As you mention, in designed system all of the carts travel on the floor and chain have dogs attachment to engage with the carts. this system work as you explained. my question is about tension of this system for absorbed shock.

Best Regards

Hadi Marvi ■

Take Up Thy Bed...

Your answer lies in the take-up arrangement, pure and simple.

It appears you forgot to make appropriate adjustment although I cannot foresee how worker introduced parts can introduce shock which is sufficient to cause trouble.

I suggest you look elsewhere for the source of trouble::: after you have introduced some float into the take up! ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Chain Conveyor Tension

Hello

I design a chain conveyor to pull 12 carts that linked together. the conveyor installed at the end of line and pull all of the linked carts. The schematic of this as attached. I consider a tension at the end of conveyor but it didn't worked correctly. Now i want to know how i can solve the problem. I think that the position of tension is not correct. The chain conveyor used in the assembly line. the worker installed parts on the cart.

Thanks & Regards

Hadi Marvi ■