Re: Cost Of Steelmaking

The question is beyond the scope of these forums. Metals refining embraces several disciplines & bulk handling is only a minor cost contributor to the process. ■

Cost Of Steel Making

I am doing some research about various method of steelmaking plant in two cases:

1- investment cost

2- operating cost

so that I can choose the best economical solution for producing steel from iron ore.

please inform me:

1- about your experiences for advantages and disadvantages of two basic method BOF and DRI.

2- References which I can compare cost of these methods numerically.

thanks in advance

Bof steel making and DRI are not competing technologies .

Bof is a process for refining liquid steel, you can feed DRI in a BOF as a coolant , and as a source of iron and carbon.

If you are to use a Bof as a way to produce steel from Iron Ore , you might be thinking on a Corex or one of its derivates , like Hismelt.

let me know more details and i will be glad to orient you. Check the page from Innova technologies , ex HYL, or contact one of the sales reps, the sdame can be done with Midrex from Kobe and Hismelt from Rio Tinto.

.

Marco ■

Iron And Steel Making

assume a plant as below:

1- capacity: 1.4 million ton per year

2- iron ore: 45%

3-production: steel

what is the best way for iron making and steel making?

thanks

href="http://vaporizers.net/no2-vaporizer/" target="blank">NO2 VAPORIZER

Attachments

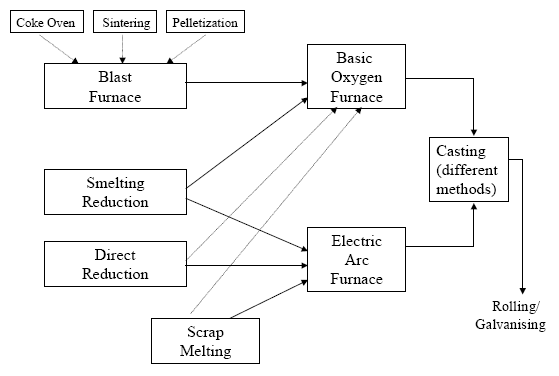

steel makingJPEG:forum_attachments/file_container/steel making.jpg (BMP)

■

Cost Of Steel Making

Lest put everything into perspective.

If you are located in an oli producing region that has excess associate gas you might be able to consider ome of the many direct reduction proeceses available that use Natural gas .

as natural agas varies in price significantly , and conveying it adds a significant cost , you need to be near.

From the gas based direct reduction proceses pelletizing adds a significant cost to your iron ore so you might want to consider a procesws that require no pelletizing , thenm you neeed toi consider what to do with the additional slagg.and th energy required to melt it.

so here you are , the location is paramount. if you are in a very cold region like Russia , the cold weather will affect some of the components of the HYL direct reduction process that in turm will affect your plant availavility .

Ideally , in the long run you do not want to mess with natural gas , unless some exdtrahordinary discovery is made , the gas price will just go up, so you might want to use goal or coal gassification nprocess , the balst furnace will give you a good bet cost wise for a large plant , you will have to solve some pollution issues ion the coke generation unit, but thet would not be unsurmountable.

So a Midrex plant with hot discarge direct into the furnace and coal gassification might be the ideal long term solution for a a cold region without oil prodiction with large amounts of assosciate gas

For other locations a HYL plant with direct Furnace hot discharge and coal gassification would be my selection.

for a larger plant , a blast furnace has no competitors .

Now you have to make your numbers , or pay for somebody to make them .

If yo are a student , you will have to do your homework. check the price od the pellets , the transport cost (beware some iron ores , advertise themselves as natural pellet ), you have to chek whether that ore is compatible with yopur selected process , the HYl process, mass flow withouth internal moving pieces has stringent requirements in regards of feed material solids flow characteristics.

Then you need to considfer the cost of gas/coal in your location , and the availavility us that gas in your plant site .

now you have to consider what are you going to do with your product , what is the steel product you will supply and who and where are the customers .

and you need to considerc the finantial terms as well.

afre that to plan your return on investement you need to consider your learning curve .

Do you hace large personell rotation , the curve will be longer .

So first . location , raw materials , energy , you.. clients waste disposal.

then process energy , labour (including training and learning curve) and enviromental cost

then finantial cost .

beware , steel used to be one of the least volatile investments ....

I believe the rules have changed . One million tons more in a saturated market has to mean , somebody has to close , the ones with the larger unit cost will become extint sooner. ■

Blast Furnace Or Dri

thanks for your guidance. but I have some questions:

1- for a larger plant , a blast furnace has no competitors . is 1.4 milion ton per year is a large plant? is there any figure for large plants?

2- composition of iron ore:

Magnetite, 55.8%Fe, 0.08%P, 1.18%S (high grade)50% of mine content

Magnetite, 33.5%Fe, 0.08%P, 1.17%S (low grade)50% of mine content

what is the best way for reduction of iron for above specification? can we use blast furnace? what is the solution for high sulfur?

3- would you please inform me the best consultants in this field both DRI(maybe MIDREX) and blast furnace?

4- where I can find the latest technologist of blast furnace?

thanks in advance

M6 ■

Re: Cost Of Steelmaking

At least in my experience , magnetite is not a good candidate for DRI . the christal is tight , although magnetite is excelent to produce pellets , for gaseous reduction is not the best choice . you can end up with unstable oxides. Can you oxidice it to a more porous oxide? using the reaction energy in the way.

If you are in india you will have to be sure that you have an abundant gas supply. if you have acces to somebody from the Birlas group you can ask about Grassim

Midrex consultant are all over the place , one choice would be Guenter Kazmeier ex Lurgy . or anybody from Voest or a user like Arcelor Mittal they have multiple Plants , I will look in my files to give you a name . although I do not believe they are using Coal gasification yet .

Innova Tec , Mr Pablo Duarte , has recently informed me that they are offering a coal gassification alternative for Midrex plants. He might be able to elaborate on this.

1.4 million tons would not be a large plant but it is if a large DR Plant for a single reactor , Contact Qatar steel they just started a mega module and would be more than happy to help you out. ■

Cost of Steelmaking

Dear Friends,

I am doing some research about various method of steelmaking plant in two cases:

1- investment cost

2- operating cost

so that I can choose the best economical solution for producing steel from iron ore.

please inform me:

1- about your experiences for advantages and disadvantages of two basic method BOF and DRI.

2- References which I can compare cost of these methods numerically.

thanks in advance

Zoloft Prilosec Nexium ■