Re: Tubes Within Tubes

John

It certainly has food for thought. My biggest concern would be that enough air could be provided at the inside horizontal bends to support the lateral forces going around that bend. How do you increase the air flow at that location? There may be a way to do it - just not my area of expertise. Heat generated from the friction if not fully supported would be another concern.

Gary ■

Gary Blenkhorn

President - Bulk Handlng Technology Inc.

Email: garyblenkhorn@gmail.com

Linkedin Profile: http://www.linkedin.com/in/gary-blenkhorn-6286954b

Offering Conveyor Design Services, Conveyor Transfer Design Services and SolidWorks Design Services for equipment layouts.

Are Water Supported Conveyors Existing Some Where?

Dear Sirs,

My feeling is that the energy consumption of using air cushion will be much higher than that of existing rollers method.

It may cause heavy air & noise pollution.

Again, if air supply got disturbed, the conveyor belt will come into contact with stationary pipes / structures.

It can cause serious damages to belt, till the rubbing is sensed by operators or by any other advanced sensors.

I have read/heard long back that there are conveyors (or being designed) to run on stationary water tables, instead of carrying rollers and return rollers.

This is to eliminate and maintenance of rollers , to bring down the project cost and energy operating cost.

Ceramic lagging on drive pulley can avoid the slippage.

Kindly share your opinion, if you have come across such conveyors.

Thanks a lot & many regards,

S.Ganesh ■

Roller Support Does Not Seem Inevitable

Gary & Sridar,

Your concerns about rubbing are similar to my own. Seized rollers would also damage a belt. I imagine that it would be possible to sense fluctuating airflow and identify a section of pipe. Air consumption for these floating/cushioned belts is presumably proportional to length. I don't know the figures but if 100m of floating belt has a power discrepancy of x watts compared to a 100m of roller supported belt then 1km will have 10x either lost of saved. Some claim a slight saving.

When operating through curves it might be necessary to drill extra bleed holes on the inside faces. This becomes an exercise in CFD where I am as green as grass.

I haven't come across water supported belts but would have to assume they operate in straight lines unless there are intermediary rollers along the curves. Also they would be restricted to troughing.

It seems that less reliance on rollers is the aim: as it was in the preceding century. ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Down On Paper

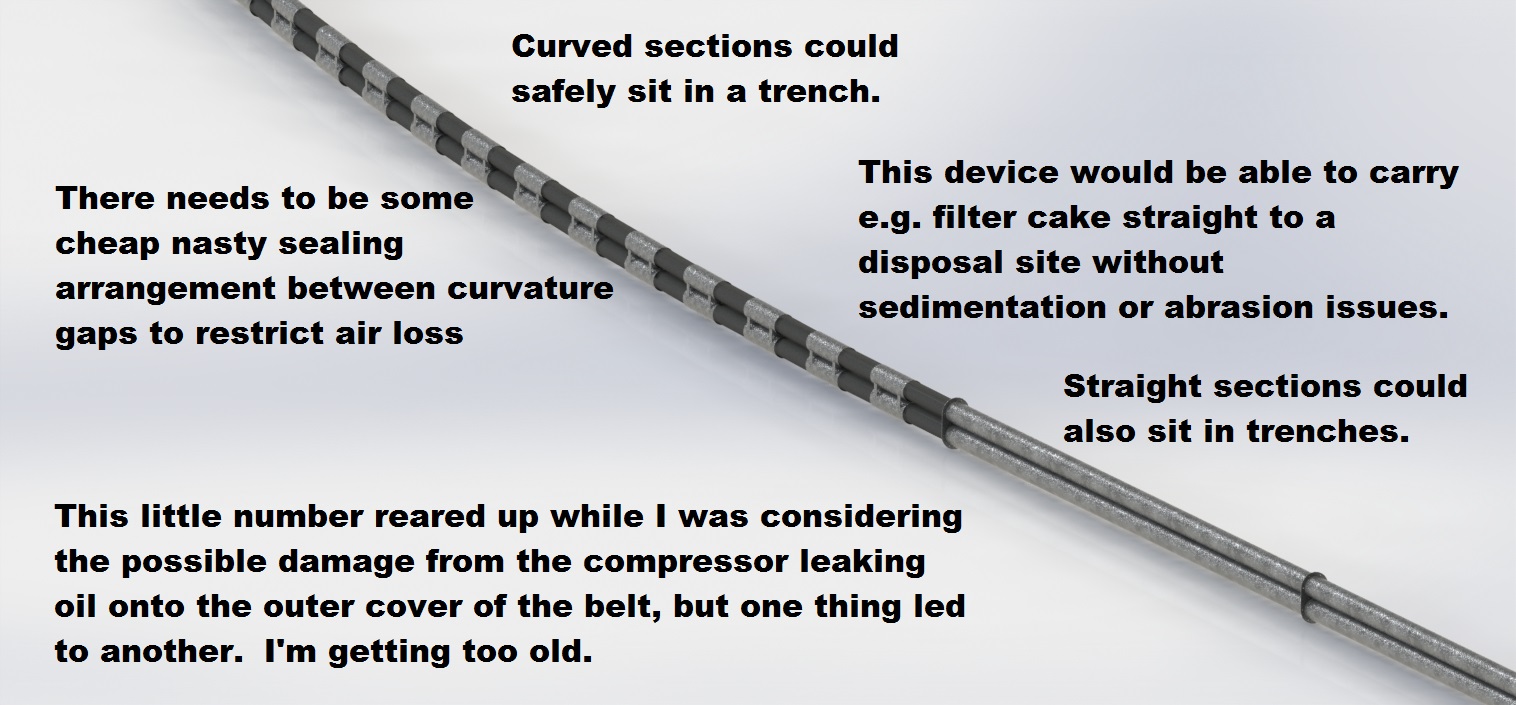

Here is a concept sketch.

href="https://forum.bulk-online.com/attachment.php?attachmentid=45174&d=1462609808" id="attachment45174" rel="Lightbox87548" target="blank">■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Waterways

Hello John,

why not adapt to Mr. Ganeshs input and use water to cushion the bulk transporting tube of the conveyor? The compressibility of water is much less than that of air, and pressurized water would imo still come in at lesser cost than air. For the support tubes, it's crucial to have removable tops, in case of any jamming / damage or similar. For the same reason (accessibility) I'd propose to avoid long (closed) support tubes.

Concluding from this another pro of your solution could be, that the transport of hot bulk may be directly feasible w/o intermediate cooling installations (bunkers etc.). So, this installation of yours could be part of a conventional tube conveyor: Just the feeding / cooling down section of it. To air / water-support bends is imo a very much demanding task both from raw physics (balance of forces, bending properties of the running tube under various load coonditions, pressure drop within piping system) as well from the technology to be applied (piping, pressurizing, nozzling).

Pls. don't forget one of Larry's favourite topics (not to say hobby ;-): the rotation of the tube and its control.

Kind regards

Roland ■

Re: Tubes Within Tubes

The water concept would limit some products from being conveyed or require extra special considerations. For example salt or any other product that is hygroscopic or prone to the moisture expediting corrosion. ■

Gary Blenkhorn

President - Bulk Handlng Technology Inc.

Email: garyblenkhorn@gmail.com

Linkedin Profile: http://www.linkedin.com/in/gary-blenkhorn-6286954b

Offering Conveyor Design Services, Conveyor Transfer Design Services and SolidWorks Design Services for equipment layouts.

Water Convert- Almost

Suppose we used piped water support for filter cake, and similar, transport. Any internal leakage would simply dilute the burden: wouldn't it?

The point about carrying waste this way is that the slurry pumps and mixers could be saved.

Does it matter the support tube is long or short. If the job stops it isn't going anywhere. A pipe blocked with material is still blocked whether there is a belt inside or not.

In many mineral processing operations there is at least as much crud being disposed of as there is ore being delivered, often more. That crud is often piped away and then there is much gnashing of teeth over pipe erosion. ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Tubes Within Tubes

Tube belt conveyors are an accepted system that can negotiate quite tortuous routes while transporting particulates in an enclosure. Many roller supports are used to guide the tube belt along the route. Could these rollers be replaced, or supplemented, by carrying the belt through rigid tubes fitted with accepted air cushion support technology? Both technologies are accepted and tubular support would incorporate weather protection and eliminate nip points. In hot climates the air cushion would serve as a cooling element. Curvature would be achieved by alternating shorter, eg 2m, lengths of support tube with similar unsupported lengths.

Support tube does not need to be steel. Air consumption is claimed to match rolling resistance in other conveying situations so there is no energy drawback in terms of length. There might even be an energy consumption reduction. Have any tests been undertaken?

What does the team think? ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com