Split?

What are the particle spectra at the spigot and overflow for each product that you classify? You are getting more in the overflow than at the spigot which sort of contradicts the idea of cycloning in the first place. How consistent is the airflow?

You produce 99.71% of sulphate but only 87% of sodium carbonate. What happened to the rest of the short supply?

How wet is the spigot product? Soda Ash is hygroscopic and you are mixing it with moist air as far as the diagram shows.

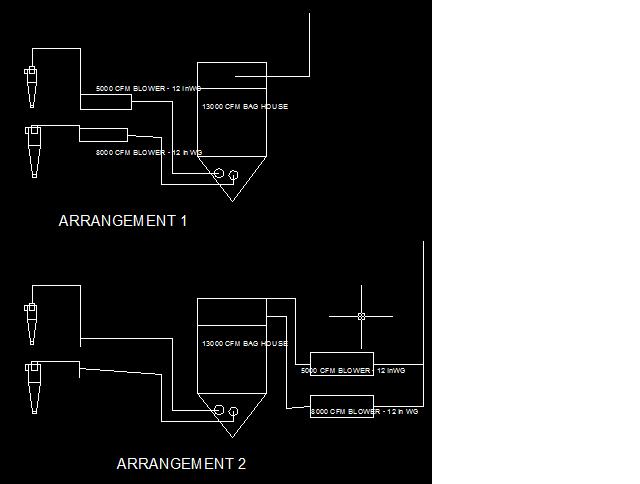

In the .pdf the baghouse inlets are the classical 'too low' type. You have to have the ID fans outside the product line. Wear and contamination spring to mind. How does the filter bag behave in arragement 1 seeing how there is no more suction downstream?

Why would someone build a plant before addressing these sort of questions? ■

Cyclone Efficiency

Your Arrangement 2 is the correct way. But, why two blowers? If you are handling hygroscopic materials, then moisture will be a big problem for your bagfilter.

You should get help from a competent, well-known bagfilter supplier.

Michael Reid. ■

Re: Cyclone Efficiency

Dear uditha, Michael

In a vacuum system, there will normally be no condensation as the temperature does not drop and due to the lower absolute pressure in the system, the RH drops and the air gets drier.

Applying cyclones for materials in the 75 micron range seems rather optimistic to me.

BR

Teus ■

Teus

Cyclone Efficiency

Uditha,

You are getting a bit less than 60% collecting efficiency from your cyclones. This is not good enough for product recovery. To get anywhere near a reasonable recovery (say 90%) with cyclones alone you will have to accept a very high pressure loss, say 2 to 3 kPa, depending.

The inlet load of 600 mg/cu.m is easily handled by a bagfilter so dispense with the cyclones.

I repeat, get the advice of a competent bagfilter supplier. This is not a difficult exercise for an experienced contractor.

Good luck,

Michael. ■

Crystally Unclear Beginnings

In a vacuum system, there will normally be no condensation as the temperature does not drop and due to the lower absolute pressure in the system, the RH drops and the air gets drier.

Applying cyclones for materials in the 75 micron range seems rather optimistic to me.

BR

Teus

Hi TT,

With soda ash the problem is not condensation. This stuff will suck water out of any air.

There are no mass balances in the thread start. I think this thread has been partly translated & resubmitted down the Homepage not too far from here. What say? ■

Efficecny

You are getting a bit less than 60% collecting efficiency from your cyclones. This is not good enough for product recovery. To get anywhere near a reasonable recovery (say 90%) with cyclones alone you will have to accept a very high pressure loss, say 2 to 3 kPa, depending.

The inlet load of 600 mg/cu.m is easily handled by a bagfilter so dispense with the cyclones.

I repeat, get the advice of a competent bagfilter supplier. This is not a difficult exercise for an experienced contractor.

Good luck,

Michael.

Thanks Mr. Michael and Mr. Tesus,

any way I will calculate cyclone efficency in lapple method (stairmand high efficency model ) , as per my calculation cyclone efficency is more than 95% , but practically as visuall I believe your calculation is more fair ?

thanks

uditha ■

Re: Cyclone Efficiency

Hi Louis,

I understand your remark that water vapor reacts also with the soda ash.

This problem is additional to the cyclone/filter issue.

Water vapor content of conveying air is more troublesome at low (or very low) solid loading ratios as the amount of air (water vapor) is high in relation to the soda ash amount and a higher soda ash percentage will bond.

This requires dried (de-watered) air, a closed air system or abandon pneumatic conveying.

The pneumatic conveying is not difficult, it is the chemistry of the product.

Take care

Teus ■

Teus

Cyclone Efficiency

Uditha,

Keep in mind that the bagfilter will always contain some residual dust. The hygroscipic nature of the dust will cause you problems even when the system is not working.

You may need to insulate the bagfilter and heat it to avoid blockages and blinding of the filter bags.

Get the advice of an experienced bagfilter contractor!!

Michael. ■

Re: Cyclone Efficiency

Dear Michael,

As Louis pointed out, that even the water vapor bonds with the soda ash, isolation and or heating will not prevent the accumulation of bonded water and soda ash in the filter over time.

The only way left is dry (de-water) the conveying air, if necessary in combination with a closed air system or abandon pneumatic conveying.

I think.

Take care

Teus ■

Teus

Primary Cleanning

Thanks Mr. Michel ,

you mean , bag house we need to insulate and supply heat flow once a day or convinent (calculated time) , earlier i was conatct several indian suppliers , their idea is filter media Glaze polypropylene (with skin coat ) is correct media , any way I was agry with you . because product is highly highgroscopic .

some dust collector engineers are setup cylone first bag house secondry cleaner , they said it will be reduce bag house dust load, but you and Mr. Tesus and other experties are not saying primary cleaner as cyclone, as my knowdlegde I know cyclone seprarotor will add high resistant to system (pressure drop ) , CFM will also not change hence bag house geometry will not change , but dust load will be reduce , becuase it will be increase bag life time Am I correct ?

Quartz silica processing factory , they have exsisting Japanese cartrige type dust collectors ,it was collect very well . but they need do further improvement , we pointed out under trap dust source points (20 numbers ). dust is highly abrasive , specific gravity also very high (2.76 ) , in this case they planning to put cyclone separators+ bag house ? do you think it also bad design ?

thanks

uditha ■

Re: Cyclone Efficiency

Dear uditha,

Your conclusion that the bag house geometry will not change, because of the CFM, is correct.

The filter area has to be designed for the same CFM.

In case of a cyclone before the filter, mainly the dust will enter the filter.

By applying a filter hopper, which takes over the function of the cyclone, the cyclone is not necessary anymore. (Although in some (rare) occasions, a cyclone is built in, in a filter receiver hopper).

From your description, it is not clear, whether you are referring to a filter cartridge or a pulsed dry air cleaned filter.

Each with its own characteristics.

Your concern about additional pressure drop is also justified.

Probably, your vacuum conveying system will be negatively influenced by an extra filter, as you are using a centrifugal fan as air mover.

Consulting a reputable and experienced manufacturer is the safest way, as they have the learning curve behind them.

Best regards

Teus ■

Teus

Cyclone Efficiency

Uditha,

The dust load is very low and you don't need a cyclone. Cfm stays the same without the cyclone, system pressure loss is less. Cyclones add an additional maintenance problem because of abrasion.

Here is a layout of a bagfilter (coloured green) in a mineral sands processing plant. The dust is very abrasive. The bagfilter has a "pre-separation" chamber with a hardened steel target plate opposite the inlet, bolted in place for easy maintenance. The velocity at the inlet is less than 15 m/s.

Get advice separately from filter bag manufacturers about the correct material. They have a very large data base of successful applications. They will advise you about surface treatments, hydrophobic coatings, foam coatings etc. Cartridge filters are not suitable for hygroscopic dusts.

It is normal for bagfilters to be insulated where high moisture is present in the conveying air, e.g., fluid bed dryers, galvanising plants. In galvanising plants, the hopper is heated to maintain the internal temp. above acid dew point. Without these features, the life of the equipment is very much reduced.

Regards,

Michael.

Attachments

ducting layout outside - iso1 (PDF)

■

Cyclone Efficiency

Hi

we fabricate high efficency (stairmand method ) two cyclones for detergent plant , product particle distribution as fallows.

ProductDiameterPercentage %

Micron

Sodium Sulphate

0-30 0.23

30-60 22.81

60-80 25.81

80-100 17.63

100-15011.66

150-200 8.72

200-40011.85

Soda Ash

0-45 4.223

45-53 10.99

53-75 54.077

75-150 18.344

PPT Silica

0-45 30.42

45-53 14.2

53-75 36.54

75-15013.745

Calcium Carbonate

0-45 19.97

45-53 5.601

53-75 54.339

75-15010.8545

average dust load 600 mg/cu m (PM 10)

after fixing cyclones (8000 CFM ) fairly higher amount scape to cyclone top, for bottom we collect around 3.5 KG (per 25 minit operation in one batch) , visuallly I believe around 5~7 kg escape top top ?

why it may be happend ?

any expert help me ?

regards

uditha ■