Wamgroup - Product Range

Product Range

• Screw Conveyors & Feeders

• Bucket Elevators

• Chain Conveyors

• Renewable Energy

• Water Management

• Dust Collectors

• Valves

• Valve Actuators

• Solids Discharging Equipment

• Bag Emptying Equipment

• FIBC (Big Bag) Filling & Emptying Equipment

• Feeding & Metering Equipment

• Level & Pressure Monitoring & Safety Components

• Silo Safety Components

• Pneumatic Conveying System Components

• Rotary Feeders (Rotary Valves)

• Vibrators & Flow Aids

• Mixers, Blenders, Conditioners, Granulators

• Solids-Liquid Separation Equipment

• ATEX compliant products

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

Today WAM® is one of the largest Screw Conveyor manufacturers in the world and in a leading position for many applications.

This position has been achieved through a strong focus on quality of manufacture and continuous investments in manufacturing technology and product development.

Over the years Screw Conveyors for specific purposes have been developed. Cement Screw Conveyors and Feeders for concrete batching plants were the first to be industrialised in the early 1970s. Later came light-duty Flour Milling Screw Conveyors with synthetic maintenance-free intermediate bearings.

Heavy-duty Cement Screw Conveyors, as used in the concrete industry, are particularly robust and equipped with self-adjusting stuffing boxes.

Extra-heavy-duty Screw Conveyors, designed for continuous operation in cement, lime and gypsum processing, come with flanged shaft couplings for easy screw replacement.

Difficult materials with a high moisture content that have a tendency to stick to the centre pipe or flight in traditional screw conveyors, such as sludge or screenings, are successfully handled by Shaftless Screw or Spiral Conveyors with ultra-heavy-duty helicoid flighting.

The expertise that has been acquired over the years has enabled WAM® to apply their technology to virtually all conveying processes. It also has resulted in high-quality yet competitively priced Screw Conveyors.

As a result of their long-term expertise in screw feeding, WAM® have developed a comprehensive range of high-accuracy Screw Feeders for both micro-feed rates and large volumes. The range includes feeders with agitator tools, feeders with flexible troughs for gently massaging and blending the material, feeders for steep angle applications and many others.

WAMGROUP`s worldwide network of sales and service subsidiaries gives every customer the opportunity to buy locally and, at the same time, to enjoy service wherever the installation might be located.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

1 - Tubular Screw Conveyors

-CAO - Tubular Trough Screw Conveyors

-TP-TE - Heavy-Duty Tubular Screw Conveyors

-TU - Tubular Screw Conveyors

-TUS - Heavy-Duty and Extra-Heavy-Duty Tubular Screw Conveyors

-TX - Stainless Steel Tubular Screw Conveyors

2 - Trough Screw Conveyors

-CA - Trough Screw Conveyors

-CX - Stainless Steel Trough Screw Conveyors

3 - Shaftless Screw (Spiral) Conveyors

-SSC - Shaftless Spiral Conveyors

4 - Vertical Screw Conveyors

-VE - Vertical Screw Conveyors

5 - Screw Feeders

-DO - Screw Feeders with Agitator

-ED - Extracting Screw Feeders

-SU - Single Shaft Screw Feeders

6 - Micro-screw Feeders

-MBF - Micro-Batch Feeders with Agitator

-MBW - FLEXFLO Micro-Batch Feeders

-SPL - Micro-Feed Screws

7 - Screw Conveyors & Feeders (specific)

-BU - Tapered Twin Shaft Screw Feeders

-CLO / CLOS - Trough Screw Conveyors for Animal By-Products

-CMC - Screw Conveyors for Fresh Concrete

-EASYCLEAN® - Minimum-Residue Tubular Screw Feeders

-ES - Cement Screw Feeders

-ESV - Volumetric Cement Screw Feeders

-MSC - Trough Screw Conveyors for Flour Mills

-MT-HT - High-Temperature Screw Conveyors

-PR - Tubular Ribbon Flight Screw Feeders

-SVE - Vertical Screw Conveyors for Sludge

-UC - Tapered Single Shaft Screw Feeders

8 - Other Screw Conveyors

-SINTSCREW® - Engineering Polymer Screws

CONSEP® - Concrete Reclaimers

MU - Live Bin Bottoms

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Re: Wamgroup S.p.a.

Screw Conveyors & Feeders

1 - Tubular Screw Conveyors

CAO - Tubular Trough Screw Conveyors

Description

The modular CAO Tubular Screw Conveyor system is highly versatile offering numerous solutions for conveying powdery or granular materials. CAO Screw Conveyors are manufactured from carbon steel with a suitable surface finishing. They are made up from a tubular trough that is equipped with at least one inlet and outlet spout, an end plate at each tubular trough end, helicoid screw flighting welded on a centre pipe with a coupling bush at each end, two end bearing assemblies complete with adjustable shaft sealing unit, and a number of intermediate hanger bearings depending on the overall length of the screw conveyor. Furthermore, CAO Tubular Screw Conveyors are equipped with a gear motor that suits the application.

Depending on the material to be handled, CAO Tubular Screw Conveyors come in a light or medium-heavy-duty design.

Both types are available with ATEX, zone 22 certification.

Function

The light-duty version, CAO¿L, is mainly used for feeding and conveying flour and flour milling by-products. The medium-heavy-duty version, CAO¿P, is mainly used in animal feed milling with products such as cereals, meals and milling by-products. In general, CAO Tubular Screw Conveyors and Feeders are suitable for applications in which a minimum material residue and maximum conservation of the particle size of the material during handling is required.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

1 - Tubular Screw Conveyors

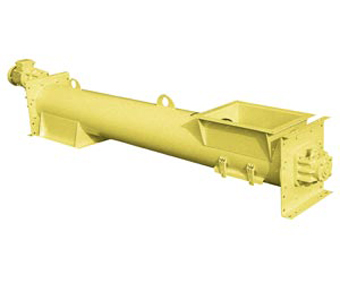

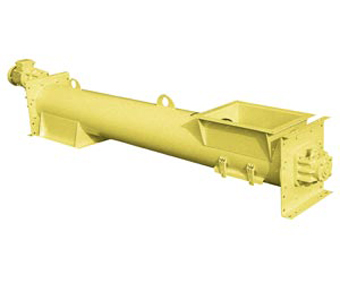

TP-TE - Heavy-Duty Tubular Screw Conveyors

Description

TP and TE-type Screw Conveyors have been conceived for medium-heavy-duty (TP) and extra-heavy-duty (TE) applications. They are manufactured from carbon steel with a suitable surface finishing. They are made up from a tubular trough that is equipped with at least one inlet and outlet spout, an end plate flanged on each tube end, helicoid screw flighting welded on a centre pipe with a coupling bush (TP) or flanged coupling (TE) at each end, two end bearing assemblies complete with adjustable shaft sealing unit, and a number of intermediate hanger bearings depending on the overall length of the screw conveyor. Furthermore, TP / TE Tubular Screw Conveyors are equipped with a gear motor and in most cases with an additional power transmission unit suitable for the application.

Function

TP / TE Tubular Screw Conveyors are used for both batch and continuous operation in applications where durability and easy replacement of those conveyor components that are subject to wear are among the main requirements.

TP Screw Conveyors are used in the same sectors as the TU-type if the throughput rate offered by the latter is not sufficient in order to meet the needs of the application (cement feeders or conveyors for cement, fly-ash, filler dust, silica fume in concrete production, hot and cold filler dust in asphalt production, plasters, sand, cement, additives in processing of premixed building materials, calcium carbonate, soda, sand, etc. in glass processing, sand and bentonite in foundries, and in many other industrial sectors).

Extra-heavy-duty TE Screw Conveyors, on the other hand, are almost exclusively used for continuous operation in cement, gypsum, and lime factories, as well as in the mining industry.

TP / TE Tubular Screw Conveyors are NOT suitable for food applications.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

1 - Tubular Screw Conveyors

TU - Tubular Screw Conveyors

Description

The modular TU Tubular Screw Conveyor system is highly versatile offering numerous solutions for conveying powdery or granular materials. TU Screw Conveyors and Feeders are manufactured in carbon steel with a suitable surface finishing. They are made up from a tubular trough that is equipped with at least one inlet and outlet spout, a welded flange at each tube end, helicoid screw flighting welded on a centre pipe with a coupling bush at each end, two end bearing assemblies complete with self-adjusting shaft sealing unit, a number of intermediate hanger bearings depending on the overall length of the screw conveyor. Furthermore, TU Tubular Screw Conveyors are equipped with a gear motor that suits the application.

TU Tubular Screw Conveyors come in a medium-heavy-duty design only.

TU Screw Conveyors are available with ATEX, zone 22 certification.

Function

The TU Tubular Screw Conveyor and Feeder system is highly versatile and offers a variety of standard solutions for handling of powdery or granular materials. Depending on the characteristics of the material different models of conveyors or feeders are available in applications like concrete production (cement, fly-ash, filler dust, silica fume), asphalt production (hot and cold filler dust), premixed building materials (dry plasters, sand, cement, additives), glass processing (calcium carbonate, soda, sand, etc.), foundries (sand, bentonite), and many others.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

1 - Tubular Screw Conveyors

TUS - Heavy-Duty and Extra-Heavy-Duty Tubular Screw Conveyors

The TUS Modular Screw Conveyor System has been developed to optimise availability from stock not only for mechanical but also fabricated equipment components. In this way delivery time for heavy-duty and extra-heavy-duty screw conveyors can be reduced considerably.

The modular trough design makes this model perform like a traditional tubular screw conveyor. At the same time it is accessible like a trough screw conveyor.

Description

The TUS Modular Screw Conveyor System covers the range of medium-heavy-duty and extra-heavy-duty applications that used to be the domain of TP-type (medium-heavy-duty) and TE-type (extra-heavy-duty) Tubular Screw Conveyors.

The modular design of the TUS-system offers additional options of a variety of trough profiles that the market has not seen so far.

TUS Screw Conveyors are manufactured from carbon steel with a suitable surface finishing. They are made up from a tubular trough that is equipped with at least one inlet and outlet spout, an end plate flanged on each tube end, helicoid screw flighting welded on a centre pipe with a coupling bush or flanged coupling at each end, two end bearing assemblies complete with adjustable shaft sealing unit, and a number of intermediate hanger bearings depending on the overall length of the screw conveyor. Furthermore, TUS Tubular Screw Conveyors are equipped with a gear motor and in most cases with an additional power transmission unit suitable for the application.

Function

TUS Modular Tubular Screw Conveyors are used for both batch and continuous operation in applications where durability and easy replacement of those conveyor components that are subject to wear are among the main requirements.

TUS Screw Conveyors are used in the same sectors as the TU-type if the throughput rate offered by the latter is not sufficient to meet the needs of the application (cement feeders or conveyors for cement, fly-ash, filler dust, silica fume in concrete production, hot and cold filler dust in asphalt production, dry plasters, sand, cement, additives in processing of dry premixed building materials, calcium carbonate, soda, sand, etc. in glass processing, sand and bentonite in foundries, and in many other industrial sectors).

The extra-heavy-duty TUS version substitutes the traditional TE-type. It is almost exclusively used for continuous operation in cement, gypsum, and lime factories, as well as in the mining industry.

TUS Screw Conveyors are NOT suitable for food-grade applications.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

1 - Tubular Screw Conveyors

TX - Stainless Steel Tubular Screw Conveyors

Description

The modular TX Tubular Screw Conveyor system is highly versatile. TX Screw Conveyors are manufactured in stainless steel with a suitable surface finishing grade appropriate for the application. Manufacture of the fabricated components is carried out on machines that guarantee a perfectly smooth surface due to which material residue is reduced to the minimum. TX Tubular Screw Conveyors are made up from a tubular trough that is equipped with at least one inlet and outlet spout, an end plate at each tube end, helicoid screw flighting welded on a centre pipe with a coupling bush at each end, two end bearing assemblies complete with adjustable shaft sealing unit, and a number of intermediate hanger bearings depending on the overall length of the screw conveyor. Furthermore, TX Tubular Screw Conveyors are equipped with a gear motor that is suitable for the application. Depending on the material to be handled TX Tubular Screw Conveyors come in a light or medium-heavy-duty design.

TX Screw Conveyors are available with ATEX, zone 22 certification.

Function

The TX Tubular Screw Conveyor system offers a variety of solutions for conveying or feeding powdery or granular materials. TX Tubular Screw Conveyors are suitable for applications in which any contamination of the material handled has to be strictly avoided and in which absolute cleanliness and perfect resistance to corrosion is required.

In particular, TX Tubular Screw Conveyors are used in environmental technology, in flour and animal feed milling, in food processing and packaging, in plastics and chemicals, as well as in the pharmaceutical industry.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

2 - Trough Screw Conveyors

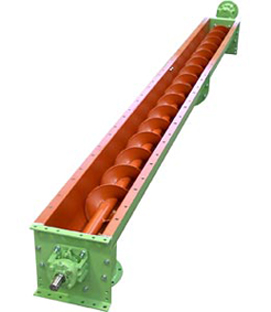

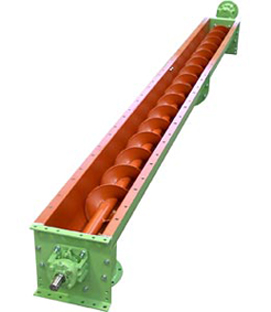

CA - Trough Screw Conveyors

Description

The modular CA Trough Screw Conveyor system is highly versatile offering numerous solutions for conveying powdery or granular materials. CA Screw Conveyors are manufactured from carbon steel with a suitable surface finishing. They are made up from a U or V-shape trough that is equipped with at least one outlet spout, an end plate at each trough end, helicoid screw flighting welded on a centre pipe with a coupling bush at each end, two end bearing assemblies complete with shaft sealing unit, a certain number of intermediate hanger bearings depending on the overall length of the screw conveyor, and bolted trough cover sections. Furthermore, CA Trough Screw Conveyors are equipped with a gear motor that suits the application.

Depending on the material to be handled CA Trough Screw Conveyors come in a light, medium-heavy, or extra-heavy-duty design.

All types are available with ATEX, zone 22 certification.

Function

The light-duty version, CA¿L, is mainly used to convey powders or granular materials in the production of pet-food, in the plastics industry, and in soap, washing powder and detergent processing. The medium-heavy-duty version, CA¿P, is mainly used in animal feed milling, in wood processing, in the chemical industry, and in environmental technology for both municipal and industrial applications. The extra-heavy-duty version, CA¿E, is mainly used in the cement / lime /gypsum, as well as in the mining industry.

According to the application various types of screws, inlet and outlet spout models are available.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

2 - Trough Screw Conveyors

CX - Stainless Steel Trough Screw Conveyors

Description

The modular CX Trough Screw Conveyor system is highly versatile. CX Screw Conveyors are manufactured in stainless steel with a suitable surface finishing grade appropriate for the application. The fabrication of the troughs is carried out on machines that guarantee perfectly smooth surfaces due to which material residue is reduced to the minimum. CX Trough Screw Conveyors are made up from a U or V-shaped trough that is equipped with at least one outlet spout, an end plate at each trough end, helicoid screw flighting welded on a centre pipe with a coupling bush at each end, two end bearing assemblies complete with adjustable shaft sealing unit, a number of intermediate hanger bearings depending on the overall length of the screw conveyor, and bolted trough covers. Furthermore, CX Trough Screw Conveyors are equipped with a gear motor that suits the application.

Depending on the material to be handled CX Trough Screw Conveyors come in a light or medium-heavy-duty design.

Both types are available with ATEX, zone 22 certification.

Function

The CX Modular Trough Screw Conveyor System offers a variety of solutions for conveying powdery or granular materials. CX Screw Conveyors are suitable for applications in which any contamination of the conveyed material has to be strictly avoided and in which absolute cleanliness and perfect resistance to corrosion is required.

In particular, CX Screw Conveyors are used in environmental technology, in flour and animal feed milling, in food processing and packaging, for plastics and chemicals, as well as in the pharmaceutical industry.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

3 - Shaftless Screw (Spiral) Conveyors

SSC - Shaftless Spiral Conveyors

Description

The SSC Shaftless Screw or Spiral Conveyor is an alternative concept to the traditional shafted screw conveyor. Material is conveyed by an extra-heavy-duty shaftless screw that slides on a low-friction, wear-resistant liner inside the conveyor trough housing.

The U-section troughs, which are longitudinally divided, are manufactured in carbon steel or in 304 L / 316 L stainless steel, including an appropriate surface treatment. Fabricated parts except the screw, which is ultra-heavy-duty, are of the medium-heavy-duty type. The cross section of the lower part of the trough is slightly wider than the side channels to allow for the liner to be inserted in the lower trough part. After complete assembly of the trough the liner is kept in place by the upper trough side channels. At one trough end there is a vertical or flush-type outlet. At the drive end the screw conveyor is equipped with an end plate holding the end bearing assembly with flanged shaft coupling with the screw. The drive unit installed suits the application.

The SSC can be loaded from above into the open trough (standard), or through an inlet spout included in a bolted trough cover (option), or from the side through a special side inlet in the loading zone of the trough (option).

Function

The Shaftless Screw (spiral) offers a larger volume capacity and the possibility of handling particularly difficult materials such as those that tend to become tangled up or those that present highly variable particle size. Construction material properties, oversize thickness, as well as a special manufacturing process make the spiral highly resistant and extremely durable. Due to the absence of intermediate bearings, obstacle-free material handling is guaranteed. The completely enclosed trough prevents any material leakage. Trough covers with appropriate gaskets enable odour-free operation and form a barrier to any atmospheric agents to enter the system. At the same time the conveyor offers maximum access to the inside for inspection and cleaning. Maintenance is reduced to the minimum due to a small number of components. There is a vast choice of liners depending on the specific material characteristics.

SSC Shaftless Screw (Spiral) Conveyors have been specially designed for handling of difficult heterogeneous materials like urban solid waste, screenings and floating matter, de-watered, thickened, conditioned sludge, packaged food, creams or pastes, waste from: meat, fish, fruit and vegetable processing. The main sectors of application are: wastewater treatment, sugarhouse rejects, fish industry, solid waste treatment, fruit and vegetable processing plants, beverage industry, pulp and paper, chemical industry, food industry in general, meat processing plants, abattoirs/slaughterhouses, restaurants, canteens, catering in general.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

4 - Vertical Screw Conveyors

VE - Vertical Screw Conveyors

Description

The VE Vertical Screw Lift System consists of a Horizontal Screw Feeder and a Vertical Screw Conveyor. The Horizontal Screw Feeder, which may feed material from a silo or hopper or simply convey it being fed by an upstream feeding device, consists of a U-shape or tubular trough in carbon steel with appropriate surface finishing. In any case the outlet zone consists of a short tubular section flanged at a right angle on the bottom section of the Vertical Screw Conveyor. A flange is welded at each end of the Horizontal Screw Feeder. The trough / tube contains a rotating screw with shaft coupling bushes at each end that are connected with the shafts of the two end bearing assemblies. The Horizontal Screw Feeder is equipped with one or more intermediate hanger bearings should its overall length require any. Furthermore, it is equipped with a drive unit suitable for the application.

The Vertical Screw Conveyor consists of a tubular housing complete with a tangential inlet in the bottom section which connects with the outlet of the Horizontal Screw Feeder, an inclined outlet spout in the top section, end flanges welded on each conveyor tube section, a rotating screw in one or more sections with shaft coupling bush at each end, a base bearing assembly complete with slide bush, and a number of intermediate hanger bearings should the overall height of the conveyor require any. The top-mounted drive unit with integrated end bearing assembly (from which the screw is suspended) and self-adjusting shaft sealing unit is suitable for the application.

The VE Vertical Screw Lift System is available in a medium-heavy-duty version only.

Function

The VE Vertical Screw Lift System consists of two units: a Horizontal Screw Feeder which receives material from a silo, hopper, or another feeder or conveyor, and a Vertical Screw Conveyor that lifts the material to a certain level. Material may be discharged into a weigh hopper, into one or more bins or silos, or into another conveyor or conveying system.

Fabricated components, screws, and bearing assemblies have been specially designed for this system to facilitate maintenance.

The VE Vertical Screw Lift System, which excels through high volumetric efficiency and excellent mechanical features, was patented in various countries in the 1980¿s.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

5 - Screw Feeders

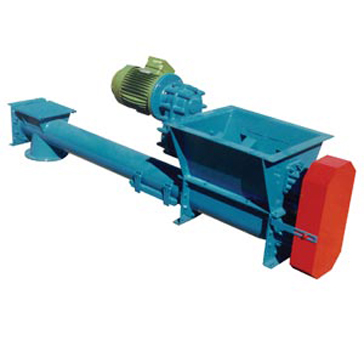

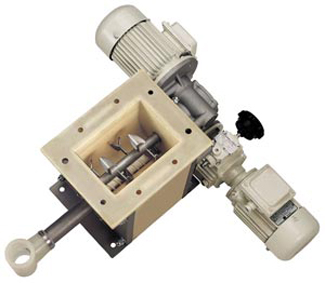

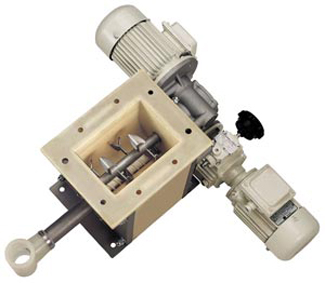

DO - Screw Feeders with Agitator

Description

DO Screw Feeders are SU-type Screw Feeders (see page) which are equipped with an additional inlet hopper including an agitator tool for better material discharge into the feeder inlet.

Performance & Technical Features - Benefits

• Complete SU-type standard screw feeder (see page on SU-type screw feeders)

• Agitator tool unit consists of flanged rectangular casing, folded blade-type agitator tool shaft, and separate WAM® gear motor

• Agitator tool facilitates loading of the screw feeder

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

5 - Screw Feeders

ED - Extracting Screw Feeders

Description

ED-type Screw Feeders consist of two parallel mounted screws of different diameters and of a flap valve integrated in the outlet spout.

The particular design of the ED Screw Feeder and a minimum clearance between screw flight and trough keeps material residue very low, guarantees high feeding precision and efficient cleaning of the inside screw feeder components. Two parallel screws also mean a wide feeding section that facilitates material discharge from the silo or hopper above.

Function

Manufactured either in carbon steel or stainless steel, ED Screw Feeders represent the ideal solution for feeding tasks in various industrial sectors.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

5 - Screw Feeders

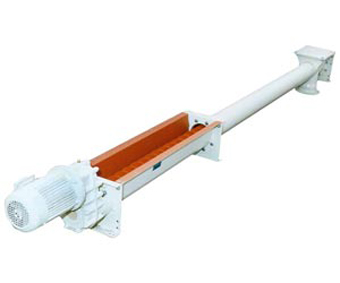

SU - Single Shaft Screw Feeders

Description

According to the cross section of the silo outlet, SU-type Single Shaft Screw Feeders are available with standard U-shaped or with flared V-section trough. In a light-duty version, SU-Feeders are used for flour and materials with similar bulk density and properties. For animal feed and similar products a heavy-duty version is available.

SU Screw Feeders are available with ATEX, zone 22 certification.

Performance & Technical Features - Benefits

• Powder coating

• Constant feed rates

• Modular design allows easy access and individual custom-design features

• Sturdy design

• Light or medium-heavy-duty helicoid flighting welded on centre pipe manufactured in carbon steel

• Light or medium-heavy-duty trough in modular flanged sections manufactured in carbon steel

• Open trough section with drilled trough flange according to WAM® standard; round outlet with drilled flange according to WAM® standard

• Robust cast iron body flanged end bearing assemblies with externally positioned bearing units and manually adjustable packing gland seals

• Splined or bolted shaft couplings

• Drive units mounted at inlet or outlet end

• Direct drives in a compact version, or with coupling transmission, or with chain or belt transmission

• Prevention of bridging, rat holing and segregation and improvement of material flow

• Maintenance-free intermediate cast hanger bearings with self-lubricating slide bushes

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

6 - Micro-screw Feeders

MBF - Micro-Batch Feeders with Agitator

The increase in cost of powders and handling of the same has resulted in more research into contamination-free feeding at highly accurate feed rates.

Our long established position in feeding and micro-feeding and our technical know-how and facilities allow us to satisfy a great variety of customer requirements. We take pride in having produced a competitively priced Micro-Batch Feeder of unsurpassable performance, with the additional benefit of being highly efficient and easy to clean.

Description

The MBF Micro-Batch Feeder for continuous volumetric feeding of powdery or granular materials consists of a steel-reinforced SINT® engineering polymer body (optionally body entirely manufactured in stainless steel), a horizontally mounted rotating agitator tool, a feeder screw beneath the agitator tool, a feeder pipe enclosing the protruding feeder screw, one drive unit each for agitator and feeder screw.

Tests on product flow and material stress have been carried out to establish optimum body geometry. Agitator and feeder tool geometry and materials have also been tested before choosing an optimal steel and engineering SINT® polymer composite.

MBF series Micro-Batch Feeders are supplied in food-grade versions with FDA-approval on request.

Function

MBF series Micro-Batch Feeders for powder and granular product feeding are particularly suitable for poorly flowing materials which tend to clog, along with adhesive products.

Fed through a bag opening hopper, a bulk bag discharger, or another feeding device, the agitator tool manages to keep the material flowing reducing at the same time the possibility of formation of lumps or bridges.

The size of the product particles is of utmost importance when choosing the type of feeder screw. For example, fine, heavy materials call for tapered screws with reduced pitch flights, while granular, lighter materials require standard pitch cylindrical screws. Poorly flowing products with cohesion or bridging problems are homogeneously fed into the feeding zone by the blending shaft which is shaped according to the product properties.

Depending on the user¿s individual requirements, MBF Micro-Batch Feeders can be supplied with alternative feeder screws and blending tools and with various accessories.

MBF Micro-Batch Feeders have been successfully operating in the following industries: food, building, plastics, chemicals, packaging, environmental technology.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

6 - Micro-screw Feeders

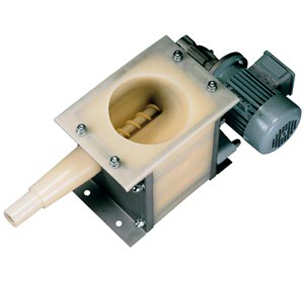

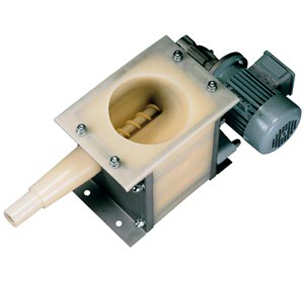

MBW - FLEXFLO Micro-Batch Feeders

Description

The MBW Micro-Batch Feeder for continuous volumetric feeding of powdery or granular materials consists of a SINT® engineering polymer FLEXFLO body with integrated feeder outlet pipe, a feeder screw and a drive unit.

Function

MBW series Micro-Batch Feeders for powder and granular product feeding are particularly suitable for free flowing and moderately flowing materials which do not tend to pack under pressure.

Fed through a bag opening hopper, a bulk bag discharger, or another feeding device, the FLEXFLO body in SINT® engineering polymer with its particular geometry ensures constant material flow and feeding through the feeder screw. To further facilitate material flow an additional pneumatic activator can be supplied on request.

Typically the MBW Micro-Batch Feeder is used in plastics processing and animal feed milling, as well as in environmental technology for polyelectrolyte feeding.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

6 - Micro-screw Feeders

SPL - Micro-Feed Screws

Function

SPL and SPS-type Micro-Feed Screws are auxiliary screws combined with a larger main screw feeder.

Before reaching the set feed rate the main screw feeder is stopped by a proximity switch to allow the Micro-Feed Screw, which is flanged beneath an opening in the pre-outlet section of the main screw feeder pipe, to feed the missing quantity of material with high accuracy through the outlet of the main screw feeder into the weigh hopper.

Performance & Technical Features - Benefits

• Low rotation speed (SPS)

• Screws in anti-wear material

• Screws with heavy-duty flighting

• No outlet end bearing (SPS)

• Connecting hopper between main and Micro-Feed Screw

• Wide range

• Possible to feed any kind of material including highly abrasive products

• High feeding accuracy

• Easy maintenance

• Reduced speed direct drives

• Screws with reduced diameter

• Full bore through outlet

• Easy inspection

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

7 - Screw Conveyors & Feeders (specific)

BU - Tapered Twin Shaft Screw Feeders

Description

The BU Twin Shaft Screw Feeder is equipped with a tapered inlet trough that follows the shape of the tapered inlet sections of the screws, enclosing them almost completely from below.

BU are manufactured from carbon steel. The upper trough flange is fitted to match the outlet of the bin / hopper.

Function

The BU Twin Shaft Screw Feeder is an option for users who require an efficient discharging feeder from bins or hoppers. The BU has been specially designed for handling of non homogeneous products (wood chippings, paper, etc.), materials from the flour milling industry (bran, flour, etc.), and bridging products (sawdust, soy, etc.).

BU Screw Feeders are available with ATEX, zone 22 certification.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

7 - Screw Conveyors & Feeders (specific)

CLO / CLOS - Trough Screw Conveyors for Animal By-Products

Description

Extra-heavy-duty CLO and CLOS Trough Screw Conveyors are manufactured from carbon steel with a suitable surface finishing (in general hot galvanised fabricated parts). Depending on the application, they are made up from troughs with different shapes and configurations. They are equipped with an inlet and an outlet spout, an end plate at the drive end for fitting of an end bearing assembly, an end plate for trough closure at the opposite trough end, shaftless extra-heavy-duty helicoid screw flighting flanged on the shaft of the only end bearing assembly. The screw slides on replaceable bars fixed on the trough bottom. The shearing effect between screw and bottom bars generated during material transport helps to shred fibrous material. Furthermore, CLO / CLOS Screw Conveyors are equipped with a gear motor that suits the application.

Function

Designed for continuous operation, CLO and CLOS Trough Screw Conveyors are used for conveying slaughtering by-products like bones (entire and ground), hooves, heads and fat.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

7 - Screw Conveyors & Feeders (specific)

CMC - Screw Conveyors for Fresh Concrete

Description

CMC Screw Conveyors are manufactured from carbon steel with a suitable surface finishing. They are made up from a U-shape trough with a wear-resistant rubber drop bottom. CMC has an outlet spout at one trough end, an end plate at each trough end, helicoid screw flighting welded on a centre pipe with a coupling bush at each end, two end bearing assemblies complete with shaft sealing unit, and a bolted trough cover. Furthermore, CMC Screw Conveyors are equipped with a gear motor that suits the application.

The inlet zone is equipped with adjustable mixing paddles.

Function

CMC Screw Conveyors are used in the precast concrete industry to convey fresh concrete from the compulsory mixer to the moulds as an alternative to belt conveyors that, unlike screw conveyors, bear the risk of segregation of the concrete. To keep the concrete homogeneous and to reduce the absorbed drive power the mixing paddles in the inlet zone are adjustable. By changing the angle of the paddles the concrete throughput rate can be altered. Due to the rubber drop bottom trough large aggregate particles that end up between screw and trough will not block the unit as the rubber will let them pass. The drop bottom can be quickly opened and closed for cleaning and easily replaced when worn out.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

7 - Screw Conveyors & Feeders (specific)

EASYCLEAN® - Minimum-Residue Tubular Screw Feeders

Description

EASYCLEAN® Screw Conveyors and Feeders, which are entirely manufactured in stainless steel, are a customised version of the modular TX Tubular Screw Conveyor System.

EASYCLEAN® Screw Conveyors consist of a tubular casing equipped with at least one inlet and outlet spout, one end plate at the drive end to carry end bearing assembly and drive unit, a tube cover plate complete with screw fixing locator for support of the screw at the end opposite the drive unit, a rotating screw with shaft coupling bushes at each end, a gear motor with integrated end bearing assembly complete with adjustable shaft sealing unit in accordance with the requirements of the application.

To satisfy the needs of the most demanding industrial sectors, EASYCLEAN® Screw Conveyors or Feeders come with a high finishing grade. Finishing of fabricated components takes place on machine tools that guarantee perfectly smooth surfaces in order to reduce material residue inside the screw conveyor.

EASYCLEAN® Screw Conveyors and Feeders are available with ATEX, zone 22 certification.

Function

The particular design shape and the total absence of nuts and bolts inside the EASYCLEAN® Screw Conveyor / Feeder allow quick and efficient cleaning of all the conveyor parts, as well as minimum material residue inside. To a great extent this is due to the small clearance between flight and outside tube which is obtained from a slightly eccentric position of the screw axis towards the bottom of the tube. The maximum play between flight and trough is less than 5mm (0.2 in). Furthermore, the end play of the screw between screw and end plate is 2.5mm (0.1 in). All the inspection hatches are supplied complete with a locking device that requires the use of a tool for unblocking and opening as required by the Directive 98/37/EEC and subsequent amendments. EASYCLEAN® Screw Conveyors are suitable as conveyors or feeders for powdery or granular materials in those applications in which quick access to the internal parts of the unit (e.g. for frequent cleaning) is essential.

EASYCLEAN® Screw Conveyors and Feeders are particularly used in the food industry, in plastics and chemicals processing, and, within certain limits, in the pharmaceutical industry.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

7 - Screw Conveyors & Feeders (specific)

ES - Cement Screw Feeders

In over thirty-five years the ES-type Screw Conveyor has become a synonym for cement feeding and conveying in concrete batching plants all over the world. In this period WAM® have supplied more than 200,000 units which have been operating ever since. After the turn of the new millennium it is hard to find a batching plant manufacturer anywhere in the world who would not appreciate the unrivalled technical features and quality of the ES. Apart from cement, ES-type Screw Conveyors are nowadays also used for filler and other materials similar to cement.

Description

As a customized version of the modular TU Screw Conveyor System, ES Screw Conveyors are manufactured in carbon steel with a suitable surface finishing and powder coating. They are made up from a tubular trough that is equipped with at least one inlet and outlet spout, a welded flange at each tube end, helicoid screw flighting welded on a centre pipe with a coupling bush at each end, two end bearing assemblies complete with self-adjusting shaft sealing unit (one of the bearing assemblies incorporated in the drive unit), a number of intermediate hanger bearings depending on the overall length of the screw conveyor. Furthermore, ES Screw Conveyors are equipped with a gear motor that suits the application.

ES Screw Conveyors are of the medium-heavy-duty type.

Function

ES Screw Conveyors are used for feeding or conveying of cement and filler dust in concrete batching plants, cold filler dust in asphalt mixing plants, as well as cement and similar materials in building materials processing plants.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

7 - Screw Conveyors & Feeders (specific)

ESV - Volumetric Cement Screw Feeders

Description

Designed for volumetric feeding of cement or similar materials, tubular ESV Screw Feeders are an evolution of the ES-type Screw Feeder (see page) which are equipped with a large inlet hopper including an IPM-type pressure switch (see page).

Function

The ESV Screw Feeder shuts down as soon as the IPM pressure switch signals lack of material inside the inlet hoppe

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

7 - Screw Conveyors & Feeders (specific)

MSC - Trough Screw Conveyors for Flour Mills

Description

MSC Trough Screw Conveyors are a customized version of the CA modular trough screw conveyor system. They are used in the flour milling industry, especially for conveying cereal grains, flour, and by-products such as bran. MSC Screw Conveyors are manufactured from carbon steel with food-grade surface finishing. They are made up from a U-shape trough that is equipped with at least one outlet spout, an end plate at each trough end, helicoid screw flighting welded on a centre pipe with a coupling bush at each end, two end bearing assemblies complete with shaft sealing unit, a number of intermediate hanger bearings with self-lubricating bushes depending on the overall length of the screw conveyor, and bolted trough covers. Furthermore, MSC Trough Screw Conveyors are equipped with a gear motor that suits the application.

MSC Trough Screw Conveyors come in a light-duty design only and they are available with ATEX, zone 22 certification.

Function

MSC Trough Screw Conveyors have been specially designed for handling powdery and granular materials in flour mills. Their design, their special finishing grade, and the vast range of options and accessories take the requirements of the flour milling industry into particular consideration.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

7 - Screw Conveyors & Feeders (specific)

MT-HT - High-Temperature Screw Conveyors

Description

Extra-heavy-duty MT / HT Trough Screw Conveyors or Feeders have been developed for medium-high temperature (MT series) and high temperature (HT series) applications. For this reason intermediate bearings are absent. They are manufactured either in carbon or in stainless steel with appropriate surface treatment. They are made up from a U-shape trough that is equipped with at least one outlet spout, an end plate at each trough end, helicoid screw flighting welded on a centre pipe with flanged coupling at each end, two end bearing assemblies complete with offset shaft sealing unit, and a bolted trough cover usually equipped with at least one inlet spout.

Furthermore, MT / HT Screw Conveyors are equipped with a gear motor that suits the application.

Function

Designed for extra-heavy-duty applications, MT / HT Screw Conveyors or Feeders satisfy the requirements for conveying or feeding of regenerated sand in foundries, coal power stations, or drying plants

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

7 - Screw Conveyors & Feeders (specific)

PR - Tubular Ribbon Flight Screw Feeders

Description

A customized development of the TU-type screw conveyor for hydrated lime in particular, the PR-type Tubular Screw Feeder has a ribbon flight screw and a special inlet, as well as an optional inlet hopper. Both inlet and fitted hopper are equipped with I100 fluidisation pads (see page). For process reasons this screw feeder type is usually equipped with a variable speed drive

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

7 - Screw Conveyors & Feeders (specific)

SVE - Vertical Screw Conveyors for Sludge

Description

SVE is a Vertical Screw Elevator fed by a horizontal screw feeder.

Function

Nowadays sludge handling technology requires increasingly the use of equipment and machinery like mixers, de-watering equipment, etc. To feed those machines or to unload them it is often necessary to lift the sludge to a higher level. The SVE system assures constant feed rates and further blending of the sludge. Along with these characteristics the SVE system offers various advantages.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

7 - Screw Conveyors & Feeders (specific)

UC - Tapered Single Shaft Screw Feeders

Description

The UC-type Tapered Single Shaft Screw Feeder is a customized light-duty version of the SU Screw Feeder (see page). The modular trough consists of a tapered feeding section, a central tubular section, and a U-trough-shaped conveying section.

Function

Mainly used in flour mills, the UC Tapered Single Shaft Screw Feeder has both a tapering inlet screw and casing to ensure even discharging an feeding of the material. Furthermore, material residue inside the inlet trough is reduced to the minimum

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

8 - Other Screw Conveyors

SINTSCREW® - Engineering Polymer Screws

Description

The SINTSCREW® trade-mark defines a wide range of screws (augers) for screw conveyors manufactured from SINT® engineering polymers. WAM®¿s technology in casting polymers of different types and quality has led to a great variety of design options.

Function

Know-how in SINT® engineering polymers in combination with an extraordinary manufacturing technology make these components particularly innovative and advantageous for a large number of applications. Depending on the characteristics of the application, screws having particularly elastic, anti-abrasive, or food-grade features, with constant or variable pitch, or with tapered shaft for homogeneous feeding of powdery or granular materials are available.

In many cases SINTSCREW® screws represent an alternative to traditional metallic screws.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

8 - Other Screw Conveyors

CONSEP® - Concrete Reclaimers

Description

CONSEP® is a Concrete Reclaimer used in ready-mixed concrete batching plants for recycling concrete washed out from truck mixers and in pre-cast concrete batching plants for recovery of concrete from the moulds.

Function

The solid aggregate particles (sand and gravel) having a particle size larger than 0.3mm (0.01 in) are separated from the wastewater by an inclined heavy-duty screw.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Wamgroup - Screw Conveyors & Feeders

Screw Conveyors & Feeders

8 - Other Screw Conveyors

MU - Live Bin Bottoms

Description

MU Live Bin Bottoms (Multiple Screw Feeders) are equipped with a modular trough which encloses up to 6 shafted helicoid flight or paddle screws, flanged external, fully protected end bearing assemblies complete with manually adjustable packing gland and shaft seal, a rectangular outlet spout covering the entire width of the unit, bolted end plates, splined shaft couplings for medium-heavy-duty, flanged shaft couplings for heavy-duty version.

Furthermore, MU Live Bin Bottoms are equipped with one gear motor per screw shaft or, depending on the application, with a drive unit driving more screws.

Function

MU Live Bin Bottoms are used to discharge difficult materials from polygonal hoppers / silos. In particular they are used for the extraction of biological or industrial sludge, paper scrap, wood chippings, sawdust, flour or bran in flour milling.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Bucket Elevators

Bucket Elevators

In more than 100 years RONCUZZI® has gained and consolidated a vast experience in the area of bulk solids handling. In this period RONCUZZI® has designed and supplied numerous plants and equipment of different types and capacities and for a variety of materials. Today the Company's unique know-how represents the foundation of a comprehensive Bucket Elevator range that is able to meet each and every user's requirements in terms of problem solution and reliability in time.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Bucket Elevators

Bucket Elevators

EC Bucket Elevators

Description

The EC version of Bucket Elevators has been specifically developed for vertical elevation of cereals and similar materials. Designed for the application in areas subject to the European explosion protection directive, ATEX, these Bucket Elevators are manufactured from extra-thick, hot galvanised carbon steel. The machines consist of a head and a foot section which include solidly mounted roller bearing units as supports for the bucket carrier belt, a variable number of anti-explosion trunkings equipped with ATEX-certified explosion panels, an intermediate trunking section for bucket assembly and inspection, along with all the other sheet-metal casings necessary for the enclosure of the machine. The particular design and the construction materials of the belt and buckets offer high conveying efficiency. The use of ATEX-certified antistatic, oil-repellent and self-extinguishing belts, along with buckets manufactured from high-density polyethylene (HDPE), as well as the presence of anti-skid belt sensors rotation control sensors provide a highly efficient state-of-the-art performance in compliance with the relevant standards.

Function

EC-type Bucket Elevators are used for vertical elevation of cereals and similar dry, powdery, non-abrasive, non packing materials that have a particle size between 1 and 3mm and a slide angle of less than 40 degrees. The material is introduced into a loading hopper which is included in the foot section. There the material is continuously picked up by appropriately shaped buckets which are fixed at an equal distance to an endless belt that rotates around a foot and a head roller wheel. The buckets are discharged through an outlet spout in the head section by centrifugal force after having passed the upper roller wheel.

EC Bucket Elevators are used in handling and storage plants for grain, cereals and other materials, as well as in different types of material processing plants.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Bucket Elevators

Bucket Elevators

EF Bucket Elevators

Description

The EF version of Bucket Elevators has been specifically developed for vertical elevation of flour and similar materials. Designed for the application in areas subject to the European explosion protection directive, ATEX, these Bucket Elevators are manufactured from extra-thick, hot galvanised carbon steel. The machines consist of a head and a foot section which include solidly mounted roller bearing units as supports for the bucket carrier belt, a variable number of anti-explosion trunkings equipped with ATEX-certified explosion panels, an intermediate trunking section for bucket assembly and inspection, along with all the other sheet-metal casings necessary for the enclosure of the machine. The particular design and the construction materials of the belt and buckets offer high conveying efficiency. The use of ATEX-certified antistatic, oil-repellent and self-extinguishing belts, along with buckets manufactured from high-density polyethylene (HDPE), as well as the presence of anti-skid belt sensors rotation control sensors provide a highly efficient state-of-the-art performance in compliance with the relevant standards.

Function

EF-type Bucket Elevators are used for vertical elevation of flour and similar dry, powdery, non-abrasive, non packing materials that have a particle size between very fine and impalpable and a slide angle of less than 40 degrees.

The material is introduced into a loading hopper which is included in the foot section. There the material is continuously picked up by appropriately shaped buckets which are fixed at an equal distance to an endless belt that rotates around a foot and a head roller wheel. The buckets are discharged through an outlet spout in the head section by centrifugal force after having passed the upper roller wheel.

EF Bucket Elevators are used in in flour milling, material handling and storage plants, as well as in different types of material processing plants.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Bucket Elevators

Bucket Elevators

EI Bucket Elevators

Description

The EI version of Bucket Elevators has been specifically developed for vertical elevation of fine aggregates and minerals. They have been designed to operate at low speed and are manufactured from extra-thick hot-galvanised carbon steel. The machines consist of a head and a foot section which include solidly mounted roller bearing units as supports for the bucket carrier belt, a variable number of trunkings, an intermediate trunking section for bucket assembly and inspection, along with all the other sheet-metal casings necessary for the enclosure of the machine. The particular design of the buckets manufactured from abrasion-resistant Nylon PA6 offers extended durability versus the highly abrasive materials handled.

The wide range of options and accessories enable a great variety of applications of EI-type Bucket Elevators providing highly efficient state-of-the-art performance in compliance with the relevant standards.

Function

EI-type Bucket Elevators are used for vertical elevation of fine aggregates such as carbonates, lime, limestone, sludge, sand, minerals and similar materials dry, powdery, abrasive, non packing materials that have a particle size between 0.4 and 1.8 kg/dm3 and a slide angle of less than 40 degrees.

The material is introduced into a loading hopper which is included in the foot section. There the material is continuously picked up by appropriately shaped buckets which are fixed at an equal distance to an endless belt that rotates around a foot and a head roller wheel. The buckets are discharged through an outlet spout in the head section by centrifugal force after having passed the upper roller wheel. EI Bucket Elevators are used in material handling and storage plants, as well as in different types of material processing plants.

EI Bucket Elevators are used in handling and storage plants, wastewater and sludge treatment plants, in ceramics processing, in the chemical and petrochemical industry, as well as in dry building material processing plants

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Chain Conveyors

Chain Conveyors

Chain or Drag Conveyors are an important cornerstone in the RONCUZZI product range developed from more than one hundred years of experience in bulk solids handling.

In fact, Chain Conveyors are amongst the most widely used conveyor types in many RONCUZZI installations for handling powdery or granular materials.

Thanks to their robust heavy-duty design, RONCUZZI Chain Conveyors meet every user¿s requirements in terms of reliability and durability.

TCG - Chain Conveyors

Description

Chain or Drag Conveyors are designed for conveying dry solids such as free flowing powders, granules, pellets and flakes.

The hot-galvanised flanged casing consists of a tail and a head section, as well as a number of modular intermediate sections. The tail and the head section contain drag and transmission roller. The design facilitates assembly and maintenance.

The drive unit is coupled on the drag roller by means of a direct geared motor or a chain transmission.

Depending on the characteristics of the material handled and on the throughput rate required, the conveyor chain may be manufactured from blank and bent links or forged with pressed links.

The chain guide is made of Polyzene® or manganese steel depending on the application.

Function

TCG Chain Conveyors have been especially designed for conveying cereals, flour or similar materials.

The product is dragged and conveyed by rectangular shaped flights along the bottom of the casing. The flights are fixed beneath a guided chain.

The conveyor enables material discharge in different points through intermediate outlet spouts equipped with electrically operated slide gates especially designed for this purpose.

Apart from various industrial processes, TCG Chain Conveyors are widely used in storage plants for cereals and similar products.

Applications

• Horizontal conveying with one or more discharge points

• Inclined conveying with one or more discharge points

• Material extraction from pits or hoppers

• Material extraction and conveying with variation of angle of inclination

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Renewable Energy

Renewable Energy

PAE - Hydrodynamic Screws

Low investment costs + low maintenance costs + high profit = high cost-effectiveness & short amortization

Description

RONCUZZI® PAE-type Hydrodynamic Screws are designed for the production of electric energy. The machine works thanks to the difference of energy potential between two different points in a water flow.

The water, thanks to the difference between two levels of natural flow, is used by a rotor (that generates energy) and then flows again into its channel. The limit of this equipment is reached with geodetic heights of more than 10 metres and flow rates higher than 5,500 l/s.

Function

PAE-type Hydrodynamic Screws can be used in many applications:

• Replacement of small turbines which require reconditioning;

• Replacement of damaged water-wheels;

• Clean water discharge in waste water treatment plants;

• Surplus water utilization in existing channels or weirs;

• Utilization of water power in long-term unused channels;

• Utlization of cooling water from electric power plants;

• Utilization of processing waste water (from paper mills, mills etc.).

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

wam_roncuzzi_coclee_pae_web (JPG)

■

Dust Collectors

Dust Collectors

Since the early 1980s WAM® have developed a unique range of compact Dust Collectors that meets the requirements of every user.

Today WAM® offers a comprehensive Dust Collector range for de-dusting and dust control for virtually all industrial applications.

Dust Collectors

- DRYBATCH® - Dry-Batch Concrete Plant Dust Collectors

- DUSTSHAKE R01 - Polygonal Dust Collectors with Shaker Cleaning

- HOPPERJET® - Hopper Venting Filter

- HOPPERTOP - Weigh Hopper Venting Filter

- SILOTOP® - Silo Venting Filters

- WAMAIR® - Polygonal Dust Collectors

- WAMAIR® Vacuum - Insertable Polygonal Dust Collectors for Negative Pressure

- WAMECO® - Clamped Round Dust Collectors

- WAMFLO® - Flanged Round Dust Collectors

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

wam_wameco-front-hopper-mou (JPG)

■

Re: Wamgroup S.p.a.

Dust Collectors

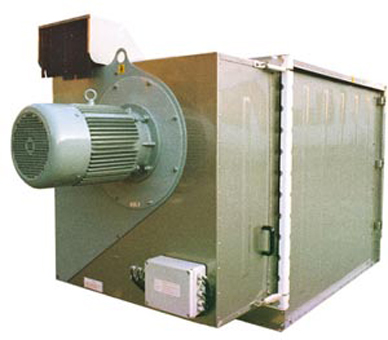

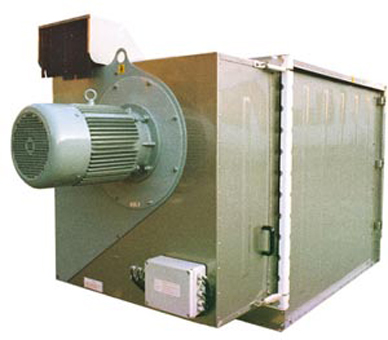

DRYBATCH® - Dry-Batch Concrete Plant Dust Collectors

Description

The polygonal shape DRYBATCH® Dust Collector is equipped with horizontally mounted filter elements, a compressed air jet cleaning system integrated in the access door and a suction fan.

Function

The DRYBATCH® Dust Collector has been specially designed for dust collection from the truck mixer inlet zone in dry batch plants during filling of the truck mixer

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Dust Collectors

Dust Collectors

DUSTSHAKE R01 - Polygonal Dust Collectors with Shaker Cleaning

Description

DUSTSHAKE R01 is a polygonally shaped SILO VENTING FILTER for silos which are filled by tankers.

Function

Dust is separated from the dirty air flow by means of a multipocket polyester filter element. Dust drops back down into the silo after elctromechanical shaking of the filter element

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Dust Collectors

Dust Collectors

HOPPERJET® - Hopper Venting Filter

Description

HOPPERJET® is a small footprint venting filter for installation on intermediate storage hoppers or weigh hoppers.

Function

HOPPERJET® is a compact venting filter for mechanically filled hoppers. Dust which is separated from the air flow by a single POLYPLEAT® or bag-type filter element drops back into the hopper after an integrated automatic reverse air jet cleaning system inside the weather protection cover has removed the dust particles from the filter elements.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Dust Collectors

Dust Collectors

HOPPERTOP - Weigh Hopper Venting Filter

Description

HOPPERTOP is a small cylindrical venting filter specifically for installation on weigh hoppers in concrete batching plants.

Function

HOPPERTOP is a compact venting filter for mechanically filled hoppers. Dust which is separated from the air flow by a single WAM® cartridge filter element drops back into the hopper after an integrated automatic reverse air jet cleaning system inside the weather protection cover has removed the dust particles from the filter elements..

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Dust Collectors

Dust Collectors

SILOTOP® - Silo Venting Filters

With almost 29,000 units working worldwide, since first going into production back in 1998, SILOTOP® has become the world¿s favourite solution for bin or silo venting.

After ten 10 years it was time for a makeover. The new model conserves the benefits of the previous version adding a few more.

Description

SILOTOP® is a cylindrically shaped dust collector for venting of pneumatically filled silos. The stainless steel body contains vertically mounted, POLYPLEAT® filter elements. The air jet cleaning system is integrated in the hinged weather protection cover.

Function

Dust separated from the air flow by special POLYPLEAT® filter elements drops back into the silo after an integrated automatic reverse air jet cleaning system inside the weather protection cover has removed it from the filter elements.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Dust Collectors

Dust Collectors

WAMAIR® - Polygonal Dust Collectors

Since start of production in 1990 WAMAIR® has represented the most versatile compact dust collector range available on the world market for industrial plant applications.

Description

WAMAIR® Dust Collectors consist of a polygonal shape 304 stainless steel casing, horizontally or vertically inserted filter elements, and a reverse air jet cleaning system integrated in the hinged access door. WAMAIR® Dust Collectors are either built in for venting applications or come as a stand-alone unit with dust collecting hopper. For suction, versions with an integrated fan are available.

Function

WAMAIR® Dust Collectors separate dust from the air flow by means of pocket or special POLYPLEAT® filter elements. Dust drops down after an automatic reverse air jet cleaning device inside the front inspection door has removed it from the filter elements.