Valves

Valves

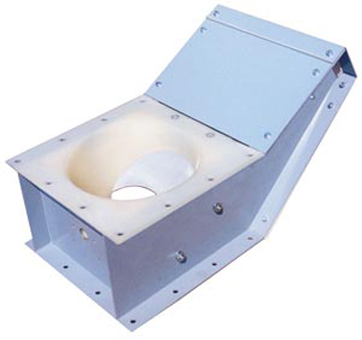

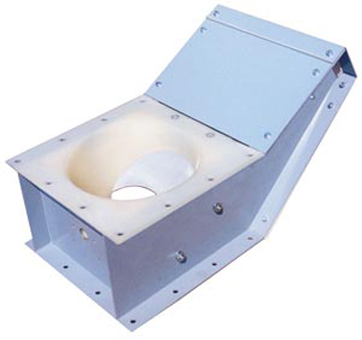

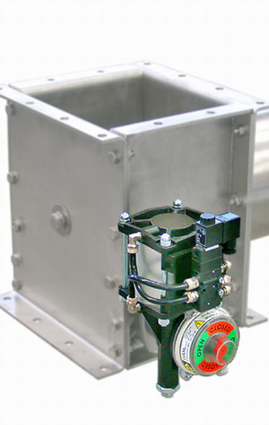

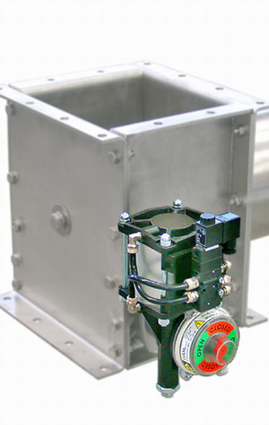

VDC - Double Dump Valves

Description

VDC Double Dump Valves consist of a robust casing and two alternately activated flaps, one installed on top of the other. The casing comes in carbon or stainless steel, whereas the flaps may be in carbon steel, stainless steel, Creusabro® or Hardox® anti-wear steel. The valve is activated either by gravity counterweights or by a gear motor with power transmission.

VDC Double Dump Valves are ideal for controlled discharging of powder or granular materials; they are mostly suitable for discharging dust from large de-dusting units and for heavy-duty applications in general, in virtually all industrial sectors. They are also used for systems that do not require continuous material flow.

Function

VDC Double Dump Valves have been developed to withstand high temperatures, for abrasive materials and for those with irregular particle size in bulk solids processes in which constant material flow is important. While most suitable for continuous heavy-duty applications, VDC Valves can also be used for light-duty batch-type operation due to their great cost-effectiveness.

Explosive, toxic, flammable and harmful materials are hazardous.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Valves

Valves

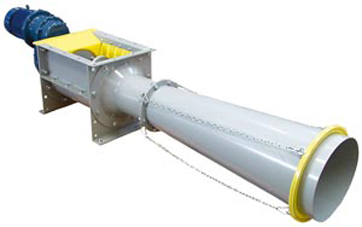

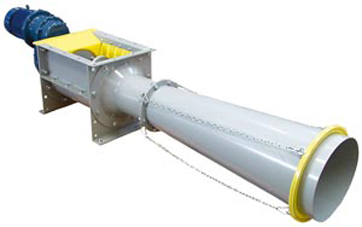

VDI - Inclined Feeder Valves

Description

The VDI Inclined Slide Valve is innovative as a whole. Its inclined blade forms an eye-shaped aperture with the asymmetrically tapered inner body. The wider the eye is opened, the more material flows through, the further it is closed, the more the material flow is reduced.

The inner body consists of a self-supporting cast in SINT® engineering polymer composite. The blade is manufactured from carbon or stainless steel. The Valve can be operated manually, electropneumatically or by gear motor. Intermediate blade positions instead of a complete opening are obtained through position sensors and made visible by an external indicator. To enforce material flow at low flow rates the dustproof VDI Valve can be equipped with an additional pneumatic hammer that imparts repetitive percussions to the internal valve body during operation.

VDC Double Dump Valves are ideal for controlled discharging of powder or granular materials; they are mostly suitable for discharging dust from large de-dusting units and for heavy-duty applications in general, in virtually all industrial sectors. They are also used for systems that do not require continuous material flow.

Function

The VDI Inclined Slide Valve adds to the simple function of material flow by gravity interception the ability to control the material flow. The particular asymmetrical geometry of the blade enables flow adjustment adding, within certain limits, volumetric feeding properties to the unit. VDI Valves can be mounted on the outlets of hoppers, tanks, silos, screw conveyors, and loading bellows. Due to the different blade options they are used in virtually every industry, food-grade applications included.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Valves

Valves

VFF - Silo Shut-Off Butterfly Valves

With more than 60,000 units operating and WAM®¿s long-term experience in the concrete industry, and due to its simple design and great performance, VFF Discharge Butterfly Valve have become the number-one product of its kind worldwide. Even though the VFF has been specifically conceived for cement discharging, it can be used for other dry non-packing materials too.

Description

The VFF Silo Discharge Butterfly Valve is manufactured from a single-piece fabricated carbon steel body lined with WAM®¿s polymer composite SINT®. Due to the four corner slots the integrated upper square flange shown in the top left photograph can be adapted to different sizes of silo outlet flanges. The valve disc is manufactured from surface-treated carbon steel.

Function

VFF Discharge Butterfly Valves are used in all types of building material processing plants wherever interception of gravity-fed dry materials is required. They are fitted beneath hoppers, bins, or silos. Due to their special design and to the engineering materials used, they have been for many years a particularly economic and efficient solution.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Valves

Valves

VFS - Butterfly Valves

With 350,000 units operating worldwide, WAM®`s VFS-type Butterfly Valves for powdery and granular materials represent one of the Group¿s most industrialized products.

Description

VFS Butterfly Valves consist of two high-pressure die-cast semi-bodies manufactured from aluminium alloy, a swivel disc in SINT® polymer composite or cast iron, and a pre-stressed elastomer seal.

For the food industry a version with stainless steel disc and an FDA-approved integral seal is available.

While V1FS has a top flange and a beaded bottom section suitable for the attachment of a flexible sleeve, the V2FS comes with an identical top and bottom flange.

Function

For closing bins, hoppers and silos containing powders or granular materials, VFS Butterfly Valves are among the most widely used equipment worldwide.

What used to be custom-built items for specific applications, have been turned by WAM® into a mass-produced industrial product with features that allow extremely versatile use.

VFS Butterfly Valves are used in all types of powder and granular material processing plants where interception of gravity-fed or pneumatically conveyed dry materials is required. They are fitted beneath hoppers, bins, silos, screw or other type conveyors, or to intercept pneumatic conveying ducts. Due to their special design and to the engineering materials used, they represent a particularly cost-effective yet most efficient solution.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Valves

Valves

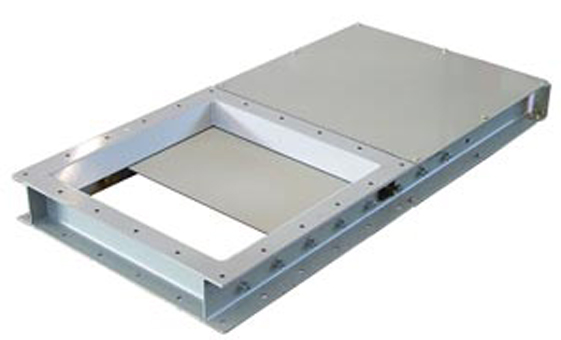

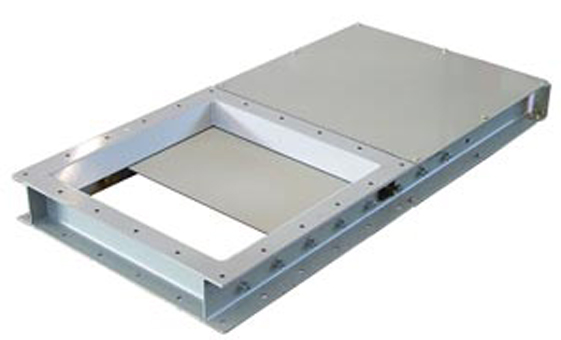

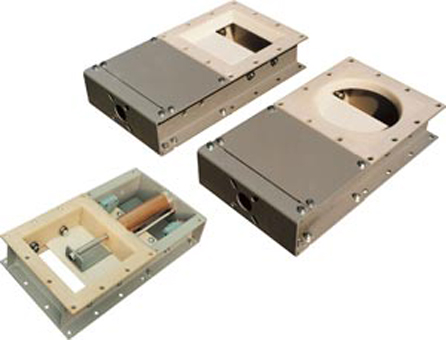

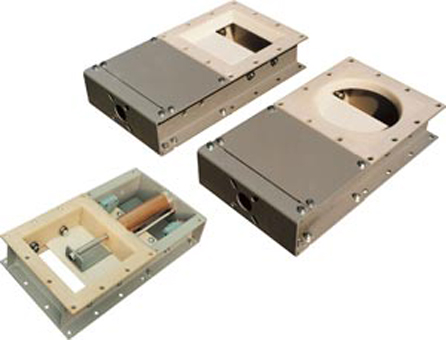

VG-VGR - Fabricated Slide Valves

Description

The VG-type Slide Gate Valve, which is entirely manufactured in carbon steel, ensures safe interception and excellent durability. The ideal equipment for heavy-duty applications, the VG Slide Gate Valve is available in larger sizes than the VL-type (see relevant page) and is equipped with two replaceable seals. In the VG version the Slide Gate Valves have a square cross section, in the VGR version a rectangular one.

Function

VG Slide Gate Valves are used in all those plant applications where interception of gravity material flow is required. The Valves are mounted on the outlets of hoppers, tanks, silos, mechanical conveyor, and on loading bellow inlets. VG Slide Gate Valves are suitable for virtually all industrial sectors including the food industry.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Valves

Valves

VL - SINT® Slide Valves

Description

VL-type Slide Valves consist of a two piece carbon or stainless steel frame, which is partly coated with WAM®¿s unique SINT® engineering polymer composite, and a sliding blade manufactured either in the same material or in carbon or stainless steel. The use of SINT® engineering polymer composites considerably increases resistance to abrasion compared to traditional valves.

In the VLQ version the valves have square, in the VLC version a circular opening. The VLS version with square opening has pneumatic actuator integrated in the frame.

Function

VL Slides Valves are used where flow of a bulk solid caused by gravity or transport has to be intercepted. Valves may be fitted to hopper or silo outlets, to the inlets and outlets of mechanical conveyors and to the inlet of telescopic loading spouts. For the outlets of conveyors in particular, the VLS version with integrated pneumatic actuator is a valid option due to ist compact overall dimensions.

The special geometry of the VL Slide Gate Valves and the different options of blade design enable their application in virtually every sector including the food industry.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Valves

Valves

VSS - Ball Segment Valves

Description

The VSS Ball Segment Valve consists of a carbon or stainless steel casing lined with SINT® engineering polymer which acts as a seal. Due to the combination of the seal and the smooth finishing of the closing segment, which is also manufactured in SINT® polymer, the valve is perfectly dustproof. The closing segment is adjustable in height to re-establish sealing properties after a certain period of operation.

Function

For intercepting material flow from bins, hoppers, silos, processing machinery, or pneumatic transport of materials with poor flowability, the use of an VSS Ball Segment Valve is often the most appropriate choice.

Unlike butterfly valves, Ball Segment Valves offer a free cross section in the open position. An unhindered material flow is the result. Viewed from the top, no other free flow valve offers any smaller overall dimensions.

VSS Ball Segment Valves are used virtually in all industrial sectors.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Valves

Valves

RV - RVR - Drop-Through Rotary Valves

Description

RV Drop-Through Rotary Valves with square inlet and RVR with a circular inlet consist of a tubular cast iron or stainless steel casing, a horizontally mounted rotor with a certain number of V-shaped cross section compartments, a drive unit and a casing cover opposite the drive end.

Function

RV and RVR Rotary Valves have been developed for maximum versatility in application. They are suitable for controlled discharging and feeding of powdery or granular materials from silos, hoppers, pneumatic conveying systems, bag filter houses, or cyclones.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Valves

Valves

RVC - Drop-Through Rotary Valves

Description

RVC Drop-Through Rotary Valves consist of a tubular cast iron or stainless steel casing, a horizontally mounted rotor with a certain number of oblique V-shaped cross section compartments, a drive unit and casing covers at both ends.

Function

Two compartments at a time of the continuously turning rotor are filled up with material through the inlet at the top of the Rotary Valve. After less than half a turn the material falls through the bottom opening through outlet with the same cross section opposite the inlet.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Valves

Valves

RVS - Blow-Through Rotary Valves

Description

RVS Blow-Through Rotary Valves consist of a tubular cast iron or stainless steel casing, a horizontally mounted rotor with a certain number of oblique V-shaped cross section compartments, a drive unit and a casing cover at each end..

Function

Two compartments at a time of the continuously turning rotor are filled up with material through the inlet at the top of the Rotary Valve. After less than half a turn the material falls through the bottom opening into an air stream passing through a pneumatic conveying pipeline connected with the bottom part of the Rotary Valve.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Valves

Valves

VAD - Diverter Valves for Pneumatic Conveying

Description

VAD Diverter Valves consist of an aluminium die-cast casing and a swivel flap that closes one duct or the other. The range suits common pipe standards used for pneumatic conveying. Internal sealing of the body is achieved through low friction gaskets.

Surface treatment is available to make the valves suitable for operation with different materials.

Function

VAD-type Diverter Valves are suitable for use in pneumatic conveying lines for handling any type of product in powder or granular form.

Through activation of the actuator direction of the material flow is changed. VAD-type Diverter Valves guarantee minimum pressure loss and contamination-free, pressure-proof operation.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Valves

Valves

VCP - Spring-Loaded Pressure Relief Valves

VCP Pressure Relief Valves are the last resort when abnormal pressure conditions endanger the silo structure. This is why sudden excess or suction pressure inside the silo must be dealt with instantaneously. Even though ideally a Pressure Relief Valve should never have to go into action, it must be efficient and reliable if needed.

With more than 70,000 units installed worldwide, VCP Pressure Relief Valves have given evidence of being totally reliable under the most different conditions.

Description

VCP Pressure Relief Valves consist of a cylindrical casing with a bottom flange to be connected with a spigot welded on the silo roof, a disc shape inner steel lid for negative pressure operation held in position by a central spring rod, an outside steel ring for excess pressure kept in position by three spring rods, gaskets, and a weather protection cover.

Function

In the VCP Pressure Relief Valve, helical springs keep the valve lids closed when the pressure value remains within the preset limits. The three outside spring rods keep the external ring-shaped lid firmly closed as long as the force generated by the pressure inside the silo does not overcome the spring force. Once the pressure exceeds the preset value the lid is pushed up and the pressure can escape. The smaller lid covers the central circular opening of the external lid from below. It is held in the middle by a single spring rod and is pressed onto the external lid by the normal air pressure inside the silo. In the event of suction pressure, the spring is compressed and allows the lid to drop. The air entering the silo from outside ensures rapid pressure balance and pushes the central lid back up into the "closed" position.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Valves

Valves

VM - Pinch Valves

Description

The body of the VM Pinch Valve is manufactured in aluminium alloy. The sleeves are made from fabric-reinforced material. The sleeve support bushes are either made from aluminium alloy, hardened carbon steel, or 304/316 stainless steel.

Function

VM-type Pinch Valves are used for interception of the material flow in pneumatic conveying systems, or other pipelines. In addition, they can be installed as a locking device for silo filling pipes.

In the open position the internal cross section of the Valve is identical with the connecting pipe diameter. By introducing compressed air or, especially with small valves, water under pressure through the threaded bore into the interior of the Valve, the internal flexible sleeve is reshaped in such a way that the passage is hermetically sealed. VM Pinch Valves equally handle pneumatically conveyed powders, granules, fibres, dense mixtures and liquids.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Valves

Valves

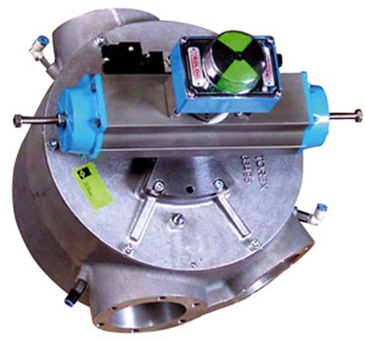

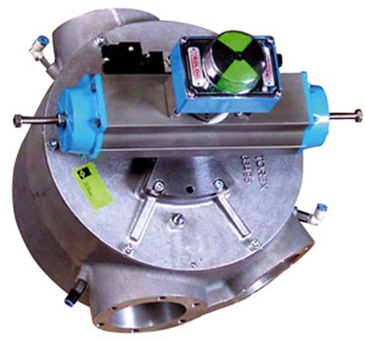

VAR - Drum-type Diverter Valves for Pneumatic Conveying

Description

The VAR Diverter Valve consists of a cast aluminium casing and cover, an inlet and two outlets. The rotating internal drum optionally closes one of two outlets which are connected with pneumatic conveying ducts.

The rotation of the internal drum is activated by means of a pneumatic actuator.

Perfect sealing is guaranteed by internal pneumatically inflatable seals.

Function

VAR Diverter Valves are suitable for conveying any type of powdery or granular material.

By means of the pneumatic actuator, which activates the rotating inner drum, the commutation of the tubular exit and, consequently, deviation of the material flow from one duct to another is obtained..

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Valve Actuators

Valve Actuators

As manufacturers of industrially manufactured valves, from the very beginning WAM® felt the need to develop Valve Actuators too. Today the customer can choose from a complete range of Manually or Electropneumatically operated, as well as Gear Motor Actuators.

These Actuators are mainly used for WAM® Valves, although application to other makes and types of equipment, such as diverter valves, dampers and valves for liquids, is possible.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Valve Actuators

Valve Actuators

AE - Gear Motor Actuator

Description

AE-type actuators are Gear Motor Actuators suitable for a 90° opening and closing of VFS-type Butterfly Valves and VSS-type Ball Segment Valves.

Function

AE actuators come with splined shaft coupling bush according to DIN 5482.

Swivel action makes limit switches (MIC 23 or LSM 0) obligatory.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Valve Actuators

Valve Actuators

AR - Gear Motor Actuator

Description

AR Gear Motor Actuators come with splined shaft coupling bush according to DIN 5482.

Function

AE actuators come with splined shaft coupling bush according to DIN 5482.

Swivel action makes limit switches (MIC 23 or LSM 0) obligatory.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Valve Actuators

Valve Actuators

CM - Manual Lever Actuator

Description

CM-type Actuators are manually operated Lever Actuators suitable for the opening and closing of VFF-type and VFS-type Butterfly Valves, as well as VSS-type Ball Segment Valves or DVA Valves.

Function

CM-type Actuators come with splined shaft coupling bush according to DIN 5482.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Valve Actuators

Valve Actuators

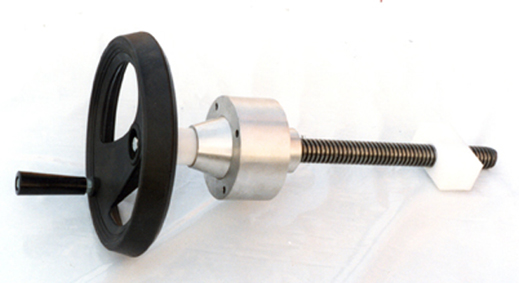

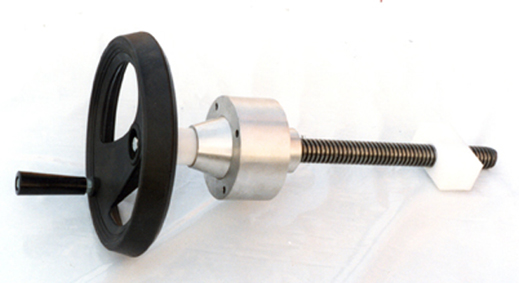

CMG - Hand Wheel Actuator

Description

The CMG-type Hand Wheel Actuators are suitable for the manual opening and closing of VLQ, VLC, VLR and VDI-type Slide Gate Valves.

Function

• Sturdy and compact design

• Interchangeable with other WAM® Actuators

• Durable

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Valve Actuators

Valve Actuators

CP - Piston Type Electropneumatic Actuator

Description

The electropneumatically operated rack and pinion-type CP Actuators are suitable for a 90° opening and closing of VFS-type Butterfly Valves, VSS-type Ball Segment Valves, and DVA-type Diverter Valves.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Valve Actuators

Valve Actuators

CRG - Gear Motor Actuator

Description

CRG-type Gear Motor Actuators are suitable for opening and closing of VLQ, VLC, VLR and VDI-type Slide Gate Valves.

Function

LSM 6 - type limit switches are obligatory for the opening and closing of the Slide Gate Valves.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Solids Discharging Equipment

Solids Discharging Equipment

Certain bulk materials cannot be stored in cylindrical silos with a tapered outlet cone because no flow aid would be sufficient to extract them. For some of those materials the outlet cross section of the silo must be increased. Others do not even allow the slightest wall angle in the outlet section and require polygonal shape silos with vertical or even negatively raked walls all the way down to the outlet. As a result, mechanical extracting and feeding devices must be adapted to the cross section of the outlet.

WAMGROUP offers a variety of equipment for discharging bulk materials.

The Conveyor Division of WAM® offers Single, Twin-Shafted Screw Feeders (see Screw Conveyors & Feeders) and Multiple Shafted Flood-Fed Screw Feeders (Live Bin Bottoms) in a customised standard design for various applications and for materials as different as flour, bran, wood chippings, sawdust, shredded paper or sludge.

EXTRAC®, specialists in extracting powders, granules and fibres, offer a wide range of vibrating Bin Activators.

TOREX® manufacture a range of Telescopic Loading Bellows (Loading Spouts).

WAMGROUP's unequalled expertise has been employed and applied over the years in developing and manufacturing a range of equipment so that standard products can be offered that suit specific applications.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

wam_zx-barge-hold-loading (JPG)

■

Solids Discharging Equipment

Solids Discharging Equipment

BA - Bin Activators

At times flowability of certain powders is so poor that discharge from silos assisted by flow aids like aeration pads, pneumatic hammers, hammer blasts or even air cannons is impossible.

In such cases a Bin Activator is the ultimate flow aid and extracting device for such materials.

Description

The BA Bin Activator is a device of tapered conical shape that due to vibration facilitates material flow from hoppers or silos. It consists of a seamless carbon or stainless steel cone manufactured on a sheet metal lathe, a seamless SINT® engineering polymer seal with integrated upper and lower flange, suspensions for connection of the Bin Activator with the silo, as well as one or two electric vibrators.

Function

To fit the BA Bin Activator, the silo cone has to be shorter than usual, leaving a wide outlet section. A flange supplied before or together with the Bin Activator is welded to the silo outlet on site. Special suspensions and a seamless flanged SINT® engineering polymer seal form a flexible connection between silo and Bin Activator. One or two electric vibrators fitted to the unit generate vibration of the Bin Activator every time the feeding device beneath the silo is started for material extraction. During operation the Bin Activator describes a gyratory movement which is transmitted to the material inside the silo. The result is smooth material flow through the Bin Activator outlet into the connected feeder.

BA Bin Activators are used in various industrial applications to facilitate discharging of powdery or granular materials from silos or hoppers. The use of this equipment ensures optimum feeding of the material and causing `mass flow` inside the silo and avoiding bridging or rat holing phenomena.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Solids Discharging Equipment

Solids Discharging Equipment

BELLOJET® ZA - Tanker Loading Bellows With Integrated Dust Collector

Description

BELLOJET® ZA Loading Bellows are used for efficient, dust-controlled loading of dry, dusty bulk solids into tankers. The spouts are provided with inner tapered cones to contain the flow of material and an outer double bellow to provide for dust removal. At the lower end of the Loading Bellow, a polymer-coated SINT® cone with special sealing properties is provided for connection to the tanker.

The BELLOJET® dust filtration system, that includes eight cartridges to provide an overall surface area of 10m2 (108 sq ft), is equipped with a 2.2 kW (3.0 HP) fan.

Function

BELLOJET® ZA Telescopic Loading Bellows are suitable for continuous loading at a maximum flow rate of 250m3/h (147 cfm) of bulk material.

The outlet can be equipped with an anti-spillage device which acts as a dustproof stopper as the Loading Bellow is being raised. The equipment features an electric winch.

The fan of the BELLOJET® dust filtration system increases the efficiency of the filtering elements. Due to an after-shutdown-cleaning-cycle, the filter elements are always in perfect condition at the start of each new loading.

First the Loading Bellow is lowered from the stand-by position towards the inlet spout of the tanker. As soon as the bellow outlet cone has settled on the inlet spout of the tanker, the slack cable switch mounted outside the transmission box stops lowering of the bellow. The limit switch inside the transmission box stops both full extension and contraction of the bellow. Material loading is started by opening the silo outlet valve.

During the filling of the tanker, the polymer SINT® coating of the outlet cone acts as a perfect dust seal. At the same time the filter fan continuously sucks dust through the external bellow into the integrated filter cartridges in the upper section of the unit and exhausts excess air. A slack cable switch activates further extension of the bellow as the tanker lowers under the increasing material weight. A level monitoring device installed in the centre of the outlet cone signals maximum material level in the tanker compartment and orders immediate closing of the silo outlet valve. Contraction of the bellow back to stand-by position starts after a delay of approximately ten seconds in order to allow the filter to evacuate the remaining dust. Once the bellow is fully contracted, the cable limit switch inside the transmission box stops operation. The preset after shut-down cleaning cycle now provides for additional pulse jet cleaning of the filter cartridges for another ten minutes.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Solids Discharging Equipment

Solids Discharging Equipment

BELLOJET® ZC - Open Truck Loading Bellows With Integrated Dust Collector

Description

BELLOJET® ZC Loading Bellows are used for efficient dust controlled discharging of dry, dusty bulk solids into open lorries / trucks. The spouts are provided with inner tapered cones to contain the flow of material and an outer double bellow to provide for dust removal.

Function

BELLOJET® ZC Telescopic Loading Bellows are suitable for continuous loading with a maximum flow rate of 250m3/h (147 cfm) of bulk material. At the lower end of the Loading Bellow, a special dust skirt seal is provided for settling on the truck skip or stockpile. The Loading Bellow is operated by an electric winch.

The fan of the BELLOJET® dust filtration system is equipped with a 2.2 kW (3.0 HP) fan that increases the efficiency of the filtering elements. Due to an after-shutdown-cleaning-cycle, the filter elements are always in perfect condition at the start of each new loading.

The dust filter includes eight cartridges to provide an overall surface area of 10m2 (108 sq ft).

First the Loading Bellow is lowered from the stand-by position towards the truck skip. As soon as the bellow outlet feet have reached the skip, the slack cable switch mounted outside the transmission box stops lowering of the bellow. The limit switch inside the transmission box stops both full extension and contraction of the bellow. Material loading is started by opening the silo outlet valve.

During the filling of the truck the filter fan continuously sucks dust through the external bellow into the integrated filter cartridges in the upper section of the unit and exhausts excess air. The level sensor mounted under the dust skirt makes the loading bellow lift progressively maintaining the skirt constantly in contact with the stockpile. Contraction of the bellow back to stand-by position is started by the operator via remote control. Once the bellow is fully contracted, the cable limit switch inside the transmission box stops operation. The preset after shut-down cleaning cycle now provides for additional pulse jet cleaning of the filter cartridges for another ten minutes.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Solids Discharging Equipment

Solids Discharging Equipment

DLP - Lump Breakers

Description

The DLP Lump Breaker consists of a square cross section casing with upper and lower flange, two horizontal rotating shafts equipped with chopping knives, a grid to hold back lumps, four end bearing assemblies with integrated adjustable shaft sealing unit, an appropriately sized drive unit complete with power transmission.

Function

The DLP Lump Breaker is the ideal device for breaking up material lumps which have formed during material handling or processing but are soft enough to be broken up.

The quick rotation of the special chopping knives through a fixed grid carry out the job. The presence of two rotor shafts results in high throughput rates.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Solids Discharging Equipment

Solids Discharging Equipment

MINIFILL® ZM - Loading Bellows for IBCs and Drums

Description

MINIFILL® ZM Loading Bellows are suitable for dust-free loading of bulk solids into drums or IBCs.

Function

The compact overall dimensions of MINIFILL® ZM make it the perfect choice where space is limited. Due to the double bellows chute design, the suction fan rate can be increased when operating with very fine dust. Two pneumatic cylinders power the unit. The lifting stroke can be 500, 750 or 1,000mm (1.6, 2.5 or 3.3 ft)..

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Solids Discharging Equipment

Solids Discharging Equipment

MU - Live Bin Bottoms

Description

MU Live Bin Bottoms (Multiple Screw Feeders) are equipped with a modular trough which encloses up to 6 shafted helicoid flight or paddle screws, flanged external, fully protected end bearing assemblies complete with manually adjustable packing gland and shaft seal, a rectangular outlet spout covering the entire width of the unit, bolted end plates, splined shaft couplings for medium-heavy-duty, flanged shaft couplings for heavy-duty version,

Furthermore, MU Live Bin Bottoms are equipped with one gear motor per screw shaft or, depending on the application, with a drive unit driving more screws.

Function

MU Live Bin Bottoms are used to discharge difficult materials from polygonal hoppers / silos. In particular they are used for the extraction of biological or industrial sludge, paper scrap, wood chippings, sawdust, flour or bran in flour milling.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Solids Discharging Equipment

Solids Discharging Equipment

ZG - Tanker Loading Bellows

Description

ZG Loading Bellows are used for efficient, dust-controlled loading of dry, dusty bulk solids into tankers. The spouts are provided with inner tapered cones to contain the flow of material and an outer double bellow to provide for dust removal.

At the lower end of the Loading Bellow, a polymer-coated SINT® cone with special sealing properties is provided for connection to the tanker.

Function

ZG Telescopic Loading Bellows are suitable for continuous loading with a maximum flow rate of 250m3/h (147 cfm) of bulk material.

The outlet can be equipped with an anti-spillage device which acts as a dustproof stopper as the Loading Bellow is being raised. The equipment features a manual or an electric winch.

A spigot on the header can be connected on site to an external de-dusting filter.

First the Loading Bellow is lowered from the stand-by position towards the inlet spout of the tanker. As soon as the bellow outlet cone has settled on the inlet spout of the tanker, the slack cable switch mounted outside the transmission box stops lowering of the bellow. The limit switch inside the transmission box stops both full extension and contraction of the bellow. Material loading is started by opening the silo outlet valve.

During the filling of the tanker, the polymer SINT® coating of the outlet cone acts as a perfect dust seal. The slack cable switch activates further extension of the bellow as the tanker lowers under the increasing weight of the material. A level control device installed in the centre of the outlet cone signals maximum material level in the tanker compartment and orders immediate closing of the silo outlet valve. Contraction of the bellow back to stand-by position starts after a delay of approximately ten seconds in order to allow the external filter to evacuate the remaining dust. Once the bellow is fully contracted, the cable limit switch inside the transmission box stops operation.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Solids Discharging Equipment

Solids Discharging Equipment

ZH - Open Truck Loading Bellows

Description

ZH Loading Bellows are used for efficient, dust controlled discharging of dry, dusty bulk solids into open lorries or trucks. The loading spouts are provided with inner tapered cones to contain the flow of material and an outer bellow to provide for dust removal

Function

ZH Telescopic Loading Bellows are suitable for continuous loading with a maximum flow rate of 250m3/h (147 cfm). At the lower end of the Loading Bellow, a special dust skirt is provided for settling on the stockpile. The equipment is available with electric or manual winch. A spigot on the header can be connected on site to an external de-dusting filter.

First the Loading Bellow is lowered from the stand-by position towards the truck skip or stockpile. As soon as the bellow outlet has reached its destination, the slack cable switch mounted outside the transmission box stops lowering of the bellow. The limit switch inside the transmission box stops both full extension and contraction of the bellow. Material loading is started by opening the silo outlet valve.

Once the bellow is fully contracted, the cable limit switch inside the transmission box stops operation.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Solids Discharging Equipment

Solids Discharging Equipment

ZN - Tanker Loading Bellows

Description

ZN Loading Bellows are used for efficient dust controlled loading of dry, non-dusty bulk solids into tankers. The ZN loading spouts are provided with a single telescopic bellow chute.

At the lower end of the Loading Bellow a sealing cone is provided for connection to the tanker inlet.

Function

ZN Loading Bellows are suitable for discharging non-dusty bulk solids. No dust suction inlet and no material level control system inside the tanker is provided. Its compact overall dimensions make ZN the perfect choice for use where space is limited. Available only with handle winch complete with transmission.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Solids Discharging Equipment

Solids Discharging Equipment

ZQ - Telescopic Loading Bellows for large capacities

Description

ZQ Loading Bellows are used for efficient discharging of powders or granular materials into ship or barge holds or open stockpiles.

The loading bellows are equipped with internal cones for better channelling of the material flow and external bellows for dust extraction.

Function

ZQ Loading Bellows are suitable for continuous duty reaching a maximum capacity of 1,800 m3/h (1,060 cfm).

At the lower end they are equipped with a skirt which prevents dust emission during discharging.

Bellows retraction is controlled by an electric winch.

The unit can be connected to a central dust collector on site via a lateral flanged spigot in the upper head.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Solids Discharging Equipment

Solids Discharging Equipment

ZX - Ship and Stockpile Loading Bellows

Description

ZX Loading Bellows are used for efficient, dust controlled discharging of dry, dusty bulk solids into ships, barges, or stockpiles. These loading spouts are provided with inner tapered cones to contain the flow of material and an outer bellow to provide for dust removal.

Function

ZX Telescopic Loading Bellows are suitable for continuous loading with a maximum flow rate of 850m3/h (500 cfm) of bulk material. At the lower end of the Loading Bellow, a special dust skirt is provided for settling on the ship hold or stockpile. The equipment is available with an electric winch only.

A spigot on the header can be connected on site to an external de-dusting filter.

First the Loading Bellow is lowered from the stand-by position towards the ship hold or stockpile. As soon as the bellow outlet has reached the ground, the slack cable switch mounted outside the transmission box stops lowering of the bellow. The limit switch inside the transmission box stops both full extension and contraction of the bellow. Material loading is started by opening the silo outlet valve.

Once the bellow is fully contracted, the cable limit switch inside the transmission box stops operation.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Bag Emptying Equipment

Bag Emptying Equipment

The EXTRAC® Division of WAM® has been specialising in the development and manufacturing of Bag Emptiers for many years.

Today¿s range offers Manual Bag Openers and Automatic Bag Splitters in various versions including a wide range of options and accessories which makes this equipment suitable for applications virtually in all industries.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Bag Emptying Equipment

Bag Emptying Equipment

COM - Waste Bag Compactors

The COM Waste Bag Compactor has been developed to meet the requirement of efficiently reducing the volume of emptied bags as they are expelled from special bag emptying machines. At the same time the COM Bag Compactor offers the smallest possible footprint. In this way removal of waste bags is more efficient and time-saving.

Description

The COM Bag Compactor for torn empty bags consists of a mild steel or 304/316 stainless steel trough with appropriate surface finishing. The U-profile trough is longitudinally split in half to facilitate replacement of the SINT® liner that helps introduction and further compression of the broken bags. The Bag Compactor is equipped with a suitable direct drive unit. At the drive end the compactor is equipped with an end plate fixed to the end flange of the trough for assembly of the end bearing complete with flanged shaft coupling for the bag compacting screw. The other trough end is connected with a tapered pipe that facilitates the progress of the compacted broken bags. At the end of this steel pipe a polyethylene tube for disposal of the waste bags can be fitted.

Function

The COM Waste Bag Compactor receives entire empty bags or bag fragments from a bag emptying device compacting the bags to approximately one eighth of their original volume. Collected in a polyethylene hose that is periodically cut and closed, the waste bags can be easily disposed of.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Bag Emptying Equipment

Bag Emptying Equipment

NST - Belt Conveyor

Description

The NST Belt Conveyor is supplied as a bag feeding accessory for RSA-type Automatic Bag Splitters.

Function

The bags are placed on the conveyor belt following the instructions in the Operation & Maintenance Manual of the RSA Automatic Bag Splitter. The design guarantees perfect grip of the bags and an optimum feed position into the RSA inlet.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Bag Emptying Equipment

Bag Emptying Equipment

RSA - Automatic Bag Splitters

The RSA Automatic Bag Splitter is an efficient system for opening of large quantities of different types of bags containing powdery or granular materials.

Description

The RSA Automatic Bag Splitter is made up of a splitting unit consisting of a trough that encloses an extra-heavy-duty splitting screw complete with an appropriate gear motor and of a screening unit consisting of a horizontal cylindrically shaped rotating screen also complete with a drive unit. On top of the screening unit a suitable fan-operated dust collector can be integrated. Alternatively the RSA is supplied with connecting spigots for a central de-dusting unit.

Function

The RSA Automatic Bag Splitter is used for splitting and emptying of single or multiple layer bags made from paper, polyethylene, polyethylene-lined paper, interwoven plastic, or polyethylene-lined interwoven plastic.

The bags are loaded manually or via belt conveyor into the inlet which is covered by a dust collecting hood. The bags drop from the belt on an extra-heavy-duty shaftless screw. Thin bags will burst open just through the impact. Bags with multiple layers or those made of elastic plastic material are pulled in by the slowly turning screw and ripped open through a scissor effect between screw and trough. This effect is increased due to a replaceable panel with integrated cutters applied to the inside of the trough. As it cuts them open the screw conveys the broken bags and their content into the revolving screen. Interwoven plastic bags are cut open by a multiple cutting disc kit mounted on top of the inlet port. The bag contents fall through the screen mesh into a collecting device mounted on the outlet of the machine. Through rotation and a slight vibration of the screen (due to its patented design) the bags are completely emptied. Paddles applied inside the screen drum repeatedly lift up the empty bags. In this manner the bags are liberated from remaining material. The inclination of the paddles helps the bags move towards the screen outlet where they drop into the built-on COM-type bag compactor (see COM).

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Bag Emptying Equipment

Bag Emptying Equipment

RSM - Manual Bag Emptiers

The RSM Manual Bag Opener represents the ideal solution for the emptying of bags containing powders or granules in a completely dust-free environment.

Description

The RSM Manual Bag Opener consists of a grille with a rest fitted to its front, The grille is mounted on top of a hopper which is supported by four feet. A fabricated hood with protection door fitted to its front covers the hopper and grille. RSM Bag Openers are manufactured in high-finish-grade materials and come with or without integrated de-dusting filter unit. In the version with integrated dust filter the filter elements are cleaned pneumatically by reverse air jet.

Function

The operator puts the bag on the rest and pushes it on to the grille. He then slits the bag open with a vertical cut and shakes it empty. While the bag content may be discharged through a hopper or by BINSWEEP®, a special rotary discharging device, into any type of feeder, the built-in fan operated, air jet cleaned dust collector filters the dust generated during emptying. The empty bag is dropped in the chute on the side which leads into the optional COM-type Waste Bag Compactor (see COM).

Manual RSM Bag Openers are designed to minimize material residue. They are suitable for numerous customizations and satisfy a large number of applications due to their modular component design.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Fibc (Big Bag) Filling & Emptying Equipment

FIBC (Big Bag) Filling & Emptying Equipment

The EXTRAC® Division of WAMGROUP, specialists in extracting powders, granules and fibrous products, develop and manufacture a range of Dischargers and Fillers for Flexible Intermediate Bulk Containers.

RBB - FIBC Filling Systems

Description

RBB-type FIBC Filling Stations consist of a steel frame and a bag filling unit including an inflatable seal that impedes dust leakage during the filling process.

Function

RBB-type FIBC Filling Stations enable efficient filling of bulk bags. The empty FIBC is attached to the four tensioners in the upper corners of the frame. Then the bag inlet is pulled over the loading spout of the station. The filling procedure starts as soon as the seal around the bag inlet is inflated. Once the FIBC is filled up it will be lifted by a forklift truck and transferred to its further destination once the FIBC has been removed from the steel frame.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Fibc (Big Bag) Filling & Emptying Equipment

FIBC (Big Bag) Filling & Emptying Equipment

SBB - FIBC Dischargers

Description

SBB-type FIBC Dischargers consist of a steel frame complete with a material discharge hopper and an upper mobile cross bar for lifting of the filled up bag by forklift truck into the Discharger..

Function

SBB is a modular system for discharging Flexible Intermediate Bulk Containers (Big Bags) in different configurations depending on the application. Easy introduction of the FIBC into the support frame and dust-free discharging along with a variety of options make SBB extremely user-friendly.

The four loops of the FIBC are attached to the hooks of the detached cross bar that has previously been laid on top of the FIBC. The cross bar with the attached FIBC is then picked up by a forklift truck and introduced into the frame of the SBB Discharger. Once the FIBC has settled on the rubber seal of the discharge hopper the outlet closing rope of the FIBC can be pulled open through the inspection hatch of the discharge hopper.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Feeding & Metering Equipment

Feeding & Metering Equipment

Over the last decades WAMGROUP have developed a range of Flow Control and Metering Feeders.

WAMGROUP associates TOREX® are in fact manufacturers Loss-In-Weight Screw Feeders, Weigh Belt Feeders, and Deflection Flow Meters.

DCC - Loss-In-Weight Screw Feeders

Description

DCC Loss-In-Weight Screw Feeders consist of a micro-screw feeder in a food-grade polymer body with stainless steel guards and feeder pipe and an optional electronically operated scale pan mounted on load cells.

Function

Wherever powders or granular materials have to be continuously fed and metered, DCC-type Loss-In-Weight Screw Feeders offer exceptional operating versatility due to a highly precise metering performance and excellent user-friendliness.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Feeding & Metering Equipment

Feeding & Metering Equipment

DCN - Weigh-Belt Feeders

Description

The DCN series of Weigh-Belt Feeders are light compact gravimetric machines. They can be used as continuous feeders (handling a predefined flow of material) or as “batch” feeders (unloading a predefined mass of material). Both operating modes are controlled by electronic instruments which control the belt speed depending on the signal read on the load cell.

Function

The DCN 0350 model is suitable for dry, free-flowing powders, sand, atomized clay and granules. It is available in three sizes: 350, 500 and 800, to be selected on the basis of the feed rate required.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Feeding & Metering Equipment

Feeding & Metering Equipment

LAMBDA - Deflection Flow Meters

Description

LAMBDA is an electronic feed rate measuring device for fine, dry and free-flowing materials.

It consists of a closed carbon or stainless steel casing with upper flanged spigot and lower flange connection, as well as an internally mounted inclined plate with a rear mounted load cell and an optional hardware module including software for visualization of real-time data readings.

Function

LAMBDA operates through deflection of the material flow onto the inclined plate linked to the off-centre load cell. The measuring unit connected with the load cell continuously reads the feed rate.

Throughput measuring and batch metering may occur either continuously or for finite quantities of materials with a maximum particle size of 10mm ( in) and good flowability properties. LAMBDA is particularly useful where space is limited and weighing needs to be carried out in the shortest time possible.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Level & Pressure Monitoring & Safety Components

Level & Pressure Monitoring & Safety Components

WAMGROUP offers a vast range of components for Level Measuring and Monitoring for powdery and granular materials stored in various types of bins or silos.

Furthermore, different models of Pressure Relief Valves for abnormal pressure conditions in bins or silos are available.

While WAMGROUP associates TOREX® are specialized in Level Measuring and Monitoring Equipment (Level Indicators and Probes; Pressure Signalling Devices and Pressure Indicators), the Valve Division of WAM® offers different models of Pressure Relief Valves for the re-establishment of normal pressure conditions inside bins or silos.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Level & Pressure Monitoring & Safety Components

Level & Pressure Monitoring & Safety Components

ILS - Continuous Level Measurement Devices

Description

ILS is a Continuous Level Measurement system for any kind of powdery or granular material stored in silos or containers.

Function

The feel weight of the ILS-system moves, microprocessor-controlled, down into the container. Upon impact on the bulk material it is pulled back to its upper stop position. By capturing the distance that the feel weight has moved the material level is measured.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Level & Pressure Monitoring & Safety Components

Level & Pressure Monitoring & Safety Components

ILT - Rotary Level Indicators

Description

ILT-type Bin Level Indicators have been designed for electric signalling by rotary action of minimum or maximum material level inside bins, hoppers or silos.

Function

As long as material is present, the paddle of the ILT Bin Level Indicator does not rotate. As soon as the material level sinks below the paddle radius, rotation restarts activating other system components. The top or side-mounted indicators are commonly used for materials having a bulk density ranging from 0.5t/m (0.02 lb per cu in) to 2t/m (0.08 lb per cu in).

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Level & Pressure Monitoring & Safety Components

Level & Pressure Monitoring & Safety Components

ILV - Vibrating Level Limit Switches

Description

ILV-type Bin Level Indicators have been designed for electric signalling by vibration of a fork of minimum or maximum material level inside bins, hoppers or silos.

Function

The ILV device is used for level monitoring in all types of bins or silos and for all kinds of powders or granular materials.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Level & Pressure Monitoring & Safety Components

Level & Pressure Monitoring & Safety Components

IPE - Electronic Differential Pressure Meters

Description

The IPE-type Electronic Pressure Meter consists of a self-cleaning wear and temperature-resistant membrane, a body manufactured in aluminium alloy, an electronic card and assembly fittings (bolts and gasket).

Function

The IPE-type Electronic Pressure Meter, by means of an electronic reading device which is activated by the membrane, supervises the pressure rising inside bins or silos during the filling and purging of the tanker.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Level & Pressure Monitoring & Safety Components

Level & Pressure Monitoring & Safety Components

IPM - Differential Pressure Gauges

Description

The IPM-type Pressure Switch consists of a self-cleaning wear and temperature-resistant membrane, a body manufactured in aluminium alloy, a contact switch and assembly fittings (bolts and gasket).

Function

The IPM-type Pressure Switch, by means of a diaphragm switch, signals the excess pressure inside bins or silos during the filling and purging of the tanker. It is also used as a level indicator in hoppers.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

Level & Pressure Monitoring & Safety Components

Level & Pressure Monitoring & Safety Components

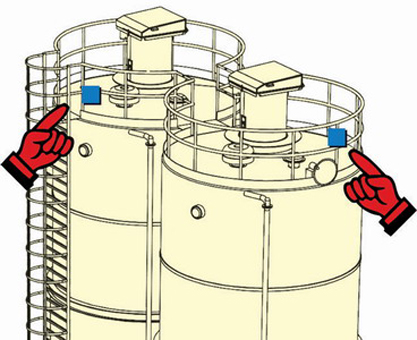

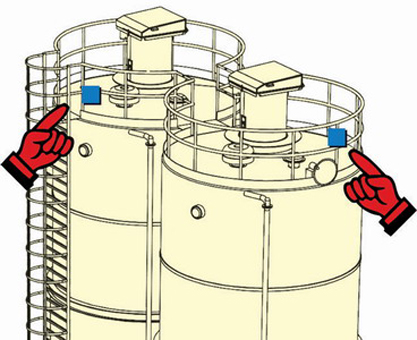

VCP - Spring-Loaded Pressure Relief Valves

VCP Pressure Relief Valves are the last resort when abnormal pressure conditions endanger the silo structure. This is why sudden excess or suction pressure inside the silo must be dealt with instantaneously. Even though ideally a Pressure Relief Valve should never have to go into action, it must be efficient and reliable if needed.

With more than 70,000 units installed worldwide, VCP Pressure Relief Valves have given evidence of being totally reliable under the most different conditions.

Description

VCP Pressure Relief Valves consist of a cylindrical casing with a bottom flange to be connected with a spigot welded on the silo roof, a disc shape inner steel lid for negative pressure operation held in position by a central spring rod, an outside steel ring for excess pressure kept in position by three spring rods, gaskets, and a weather protection cover.

Function

In the VCP Pressure Relief Valve, helical springs keep the valve lids closed when the pressure value remains within the preset limits. The three outside spring rods keep the external ring-shaped lid firmly closed as long as the force generated by the pressure inside the silo does not overcome the spring force. Once the pressure exceeds the preset value the lid is pushed up and the pressure can escape. The smaller lid covers the central circular opening of the external lid from below. It is held in the middle by a single spring rod and is pressed onto the external lid by the normal air pressure inside the silo. In the event of suction pressure, the spring is compressed and allows the lid to drop. The air entering the silo from outside ensures rapid pressure balance and pushes the central lid back up into the "closed" position.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1675-wamgroup.htm" target="blank">https://edir.bulk-online.com/profile/1675-wamgroup.htm

href="http://www.google.com/search?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk-online.com&btnG=Suche&lr=&aq=f&oq=" target="blank">http://www.google.com/search?hl=de&c...e&lr=&aq=f&oq=

Attachments

■

WAMGROUP S.p.A.

WAMGROUP S.p.A. - Corporate Profile

Since WAMGROUP Chairman and C.E.O., Vainer Marchesini, set up his first workshop back in 1969 as a one-man-operation to manufacture screw conveyors, the name WAM® has come to stand for innovation in bulk material handling technology and equipment supply.

Today, WAMGROUP manufactures and supplies a comprehensive product range including equipment for Bulk Material Handling, Dust Filtration, Waste Water, Mixing and Vibration Technology.

Strongly focused on the requirements of the market, WAMGROUP aims to produce market-oriented solutions and to turn them into a particularly user-friendly standard.

High quality and a price-performance ratio make WAMGROUP equipment the ideal choice for every project engineer and gives the customer the best deal available on the market.

Uncompromising dedication to R & D is the foundation of a vast product range and leads time and again to the development of custom-designed equipment from standardized modular components.

Highly rationalized and cost-effective CAD/CAM-supported production methods and logistics have been constantly improved throughout the years and now can be considered "state of the art".

The VISION 2000 quality management gives every WAMGROUP customer the assurance that the equipment he is going to use has been checked and tested in each phase of the manufacturing process.

WAMGROUP’s worldwide sales network including subsidiaries and distributors offers each and every user professional advice, smooth order management and a ‘round the clock’ spares service.

For major integration into overseas markets, in the 1990s WAMGROUP started to set up manufacturing and assembly plants for their major product lines in all continents.

At the beginning of the 3rd millennium WAMGROUP stands for particularly market-oriented structures and maximum synergies between the Group’s members.

More information on WAMGROUP1675 wamgroup.htm

Google Search - Websearch?hl=de&client=safari&rls=en&q=wamgroup+site%3Abulk online.com

Google Search - Images

WAMGROUP on the Portal ■