1. Introduction

As usually, the transport of the fine bulk solids, such as cement, raw meal, fly ash or coal takes place for complicated conveying line routings pneumatically. It means that the bulk solid is transported with conveying air through a piping line system. The occurring friction between bulk solid and the piping line wall, and the vertical lift of the bulk solid in vertical extending conveying lines create a pressure loss of the conveying air. Consequently, the conveying air must be provided for the product transport conveying air with a plant-specific pressure. Against this plant pressure, the bulk solid must be fed into the air flow of the conveying line. For this purpose different feeding systems are applicable.

In the past pressure vessel systems or screw pumps are used for this purpose. For more than half a decade, these systems are replaced by highly wear-resistant Ceramic rotary feeder type ZSV-H of the company KREISEL GmbH & Co.KG, Germany. The most important criterion for the use of KREISEL Ceramic rotary feeder is the energy saving during the plant operation and considerable wear resistance of the components. PPC in South Africa chose for their work in Hercules, as replacement of a screw pump a KREISEL ZSV-H 700 to save a power consumption of 130 kW for driving the screw pump.

2. Plant Description

Fig. 1 shows the technical process of cement grinding plant. The factory Hercules PPC operates a vertical roller mill for the cement grinding. The cement is deposited in subsequent baghouse. As a shut off valve below the baghouse the output rotary feeder is placed under each of the two hoppers. It guides the cement into an airslide, that transports the material to the distributor DV22.

Fig. 2a shows the installation of two screw pumps before the plant conversion. The airslide diverter feeds two feeding system Fig. 2b for pneumatic conveying:

- KREISEL ceramic rotary feeder (Fig. 2b, on the right)

- Standby screw pump (Fig. 2b, on the left)

Fig. 2a: The two screw pumps before modification

|

Fig. 2b: Stand-by pump (on the left) and new KREISEL rotary feeder (on the right)

|

With the help of pneumatic conveying the Duo-Cell silo and the packing plant are loaded. KREISEL ZSV-H has been installed so that it can load all three receiving points. The pneumatic transport proceeds over approximately 260 m with 53 m vertical routing. The conveying capacity is 150 tons per hour. The pressure generators can be used also by the ZSV-H operation. The ceramic rotary feeder and its pre-bin were fitted into the existing plant so, that no modifications on the building construction or the conveying line were necessary.

3. Commissioning of the KREISEL Ceramic Rotary Feeder

In December 2014 the KREISEL invited the plant engineers from PPC to Germany to represent the KREISEL Ceramic Rotary feeder. After detailed, constructive discussions, PPC decided to replace the screw pump through KREISEL Ceramic Rotary feeder. After 5 months of delivery time the rotary feeder was installed at the beginning of September 2015. Fig. 3 shows the KREISEL ZSV-H before the packaging at the factory in Germany.

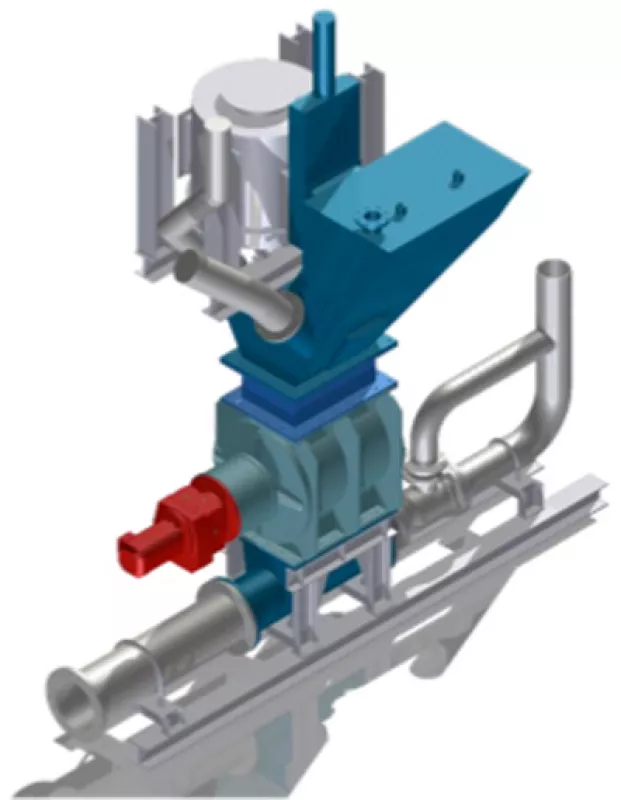

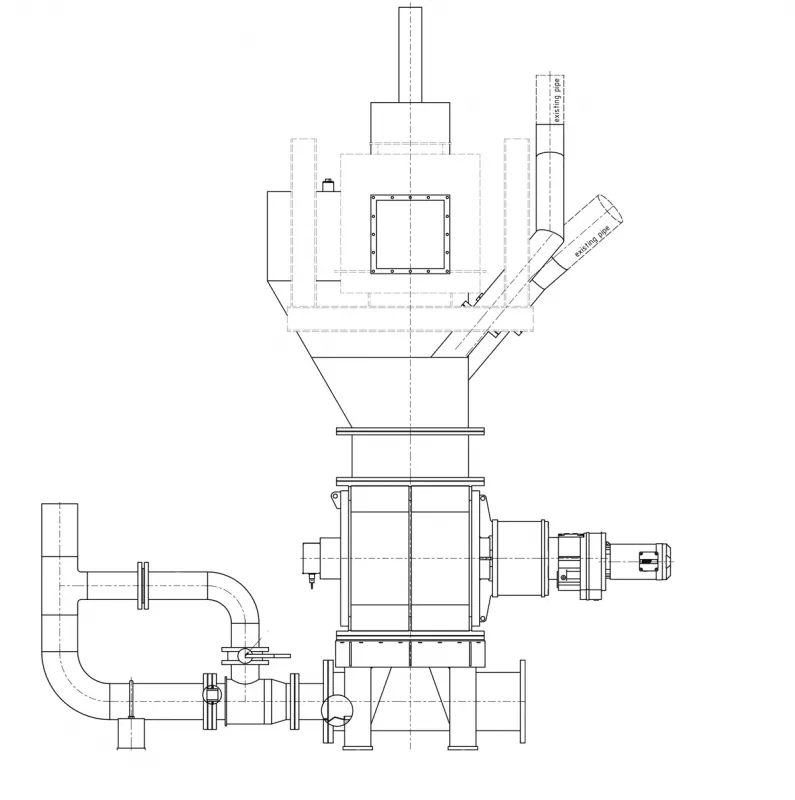

Kreisel engineered (see 3D planning extract Fig. 4) the integration of KREISEL ZSV-H in the existing plant configuration (see Fig. 5). For assembly, the existing support structures of the screw pump could be used. In a very short space of time the existing screw pump was dissambled and the Kreisel ZSV-H mounted. The plant planning was performed so that the air pipes of the pressure generators, the cement feed and the conveying capacity could be fastened optimally for the technical process.

The supervision of erection and commissioning were carried out by KREISEL. After mounting the commissioning was succeeded. After the half-day cold commissioning the warm commissioning followed. The grinding plant was started with 100 t/h. After a short time the plant capacity was increased to 110 t/h. This capacity was kept constantly overnight. Over the next two days of operation the grinding throughput was adjusted to the expected conveying capacity of the ceramic rotary feeder of 150 t / h. The conveying line back pressure was adjusted to about 1.1 bar (g). During the commissioning the increase of the grinding capacity resulted in the evaluation of the results that the ZSV-H could feed min. 180 t / h of cement into the existing conveying capacity. Due to the flow-technical development of the inlet geometry of the leakage air collector KREISEL reached maximum filling degrees in the rotary feeder. Leakage air is selectively removed and thus the maximum, constant capacity is possibly.

4. Comparison of the KREISEL Ceramic Rotary Feeder with Screw Pump

With KREISEL ZSV-H the KREISEL GmbH & Co.KG has a feeder, which reaches the contemporary customer demands with high precision. After decades of development and optimization the rotary feeders of KREISEL are already known across all industries and its reliability is proved. The ceramic lining of the product contact surfaces allows using this traditional product as feeder in pneumatic conveying systems with bulk solid. For a long time the wear, caused by flows, has been the reason not to use the rotary feeders as feeder for fine bulk solids. By using the latest ceramic elements the necessary requirements to feeders are exceeded.

KREISEL ZSV-H can not only bring their outstanding properties to the pneumatic conveying systems, but are better than the established input systems also in service life, maintenance and spare parts requirements. In the past time the usual argument for a high energy loss because of the escaping leakage air was invalidated by the use of side plates at the rotor and by the precision of the smallest gaps. A solid construction and the grinding of ceramic elements guarantee the smallest gap and define predictable leakage air quantities.

These can be compared with the energy loss of the nozzles, used in other systems. After the KREISEL ZSV-H has met the customer requirements of reliability and energy efficiency, the integration should be verified. Also here, the KREISEL ceramic rotary feeders show their thorough small footprint and low weight, and even satisfied safety officers without hesitation. Regulated space conditions and the static limits of the existing steel structure for loads and vibrations limits the room for maneuver of the manufacturers in a. On these points, the rotary feeder makes it only possible to implement the chosen customers transfer points.

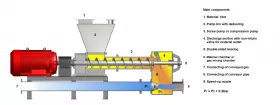

For the comparison of KREISEL ZSV-H with a screw pump, the functioning of the screw pump will be briefly explained with reference to the schematic diagram Fig. 6.

The bulk material falls through the inlet (1) in the pump surge bin (2). This is used to draw the sealing air and the air from the bulk solids. By high speed continuous compression screw (1000 rpm) the bulk solid is transported to the outlet. There occurs a strong compression of the bulk solid. This compression is supported by a check flap (4). The compression produces a high-density bulk solid plug, which is used for the sealing against the feed conveying line pressure. The solid bulk plug falls into the outlet area of the screw pump. There, it is gathered by the conveying air and transported into the conveying line. The conveying air needs to pass in the outlet housing a nozzle, or depending on the version, several nozzles. This nozzle produces a pressure drop of about 0.30 bar and serves the conveying air and fine bulk acceleration.

The differences between KREISEL Ceramic feeders and the screw pump are as follows:

Foreign bodies: If with the fine bulk solids accidentally foreign bodies, such as e.g. grinding ball remains are carried, so also these should pass through the feeder. Using the example of PPC the screw pump has a peripheral speed of >15 m/s, whereas the rotary feeder works with < 0.70 m/s. In screw pumps this can cause the breakage of the wear bushes or the end wing. In the rotary feeder, it is unlikely that these foreign bodies, especially in such a position, hit the rotor that it causes the clamps. As a rule, even the clamps cannot cause a damage of rotary feeder.

Fine bulk solid properties: The bulk solid properties of Blaine, grain size distribution, bulk density and moisture are necessary for the dimensioning of a screw pump. These parameters affect, in addition to the conveying line back pressure, the dimensioning of the motor. If these properties are changed by fluctuating processing conditions, this can lead to failure of the screw pump. Capacity losses, motor overloading and sealing problems are the results. Too fine or too coarse fine bulk solids can be fed only at low pressures (<0.5 bar), because the plug formation is insufficient. For the design of the rotary feeder, however, even the bulk solid density is crucial. The drive is exclusively determined by the dimensioning of the rotary feeder. In the plant PPC a 5.5 kW motor is installed at the rotary feeder. This absorbed capacity during the operation of less than 1 kW.