Just like my dad used to say when I would show up with a rubber mallet when he asked for a hammer, “You need the right tool for the right job.” And flowmeters are exactly the right instrument for measuring the flow rate of many solid materials.

This simple fact has led to the development of several different versions of solids flowmeter. In this article we will discuss and evaluate these, so that you too will have the right tool for your industrial flow application.

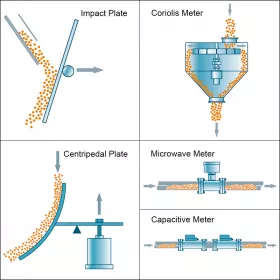

There are a handful of technologies used for metering the flow of solids:

- Impact Flowmeter – the most popular form of solids flowmeter, impact meters, as they are often called, guide the material through an infeed pipe or chute and create a specific trajectory for the material to strike a flat sensing plate. The amount of force the impact creates is measured by means of load cells or an LVDT (linear variable differential transformer). As the plate is deflected by the force of the material, the load cell or LVDT deflects and generates a signal, which is converted into a flow rate by an integrator (Fig. 2).

- Centripetal Flowmeter – this is a variation on the impact design. A centripetal solids flowmeter guides the material through a curved sensing plate, which is connected to one or more load cells. The material must be guided in parallel to the sensing plate as it enters the curve, and the tangential force exerted on the load cell(s) is transmitted to the integrator and then converted into a flow rate (Fig. 2).

-

Fig. 2: There are just a handful of working principles for solids flow meters.

Fig. 2: There are just a handful of working principles for solids flow meters.Coriolis Flowmeter – the solids coriolis flowmeter does not use the same principle as a liquid coriolis meter. In a solids application, material enters the flowmeter and is directed onto rotating vanes driven by a motor. The motor is connected to a torque arm, which is mounted to a load cell. As the amount of material fed into the coriolis meter increases, the torque on the motor increases. The load cell detects this increase and sends a signal to an integrator, which translates it into a flow rate (Fig. 2).

- Microwave Flowmeter – one of the lesser-used technologies, microwave or radar flowmeters, emits a 24 or 125 GHz microwave into the material flow in a pipe or chute. Based on the Doppler principle, the change in microwaves reflected back to the sensor is measured and transmitted as a 4 to 20 mA signal for scaling in a PLC system to become a flow rate. Microwave-based products can be used in pneumatically-fed systems, as the extra force of the material flow does not affect the measurement as is the case with the three technologies discussed above (Fig. 2).

- Capacitive Flowmeter – solids flow sensors using capacitance are based on two independent measurements. One is the change in capacitance from an empty pipe to a full pipe, which is proportional to the concentration of the material. The other is a velocity measurement, which uses two sensors to indicate the time it takes for the material to move from the first sensor to the second. The signals from these measurements are then fed into an integrator, which outputs a flow rate. Capacitive measurement can also be used with pneumatic systems (Fig. 2).

Flowmeter Technology: A Comparison

Of course, each technology has its own advantages as well as disadvantages. Following, you will find some of the more critical aspects to consider when trying to identify the best product fit for your particular application.

Impact Flowmeters: Two distinct Advantages

First, they can handle very low to very high flow rates. Second, material buildup on the sensing plate does not affect their accuracy or repeatability, as only the horizontal force of impact causes a deflection on the sensor. Any additional weight, e.g. if some material sticks, does not shift the output of the system.

The oldest of all of these technologies, impact meters have been in use for over 60 years. Impact solids flowmeters can be very compact – some are only 650 mm high, whereas others are suited for aerated gravity conveyor input and are 2500 mm tall. As the size of the unit increases, so does the cost. However, the enclosures are designed to be dust-tight and are very easy to clean and calibrate.

Centripetal Flowmeters: Higher Accuracy

Centripetal solids flowmeters take the accuracy prize. However, caution must be taken when applying this type of product. With the right material characteristics and flow, centripetal solutions can be extremely accurate. However, if the material is at all sticky – and begins to build up on the sensing plate – the signal of a centripetal flowmeter will begin to shift as the tangential force is measured. In addition, flow rates are limited with centripetal designs, but this technology also offers dust-tight enclosures and allows for easy calibration.

Coriolis Flowmeters: High flow and Accuracy, higher Power Usage

Coriolis solids flowmeters are a nice alternative for applications involving high flow rates and demanding high precision. Higher flow rates and precision seem to be the norm as process instrumentation evolves. The coriolis design is also tried and tested but it has some disadvantages. Abrasive materials can prematurely wear out the blades of the meter, which means that they must be replaced.

Large particle sizes can be a problem as they can jam or clog the discharge. The other disadvantage of a coriolis meter is that the unit is driven by a low-voltage motor. With all the other styles, typical instrumentation power supply (generally 230 VAC or less) is required for the device, whereas AC motors will need anywhere from 120 to 600 VAC.

Microwave Flowmeters: Low Cost but lower Accuracy

Microwave flowmeters are beginning to gain some ground as a low cost, low accuracy alternative to the large bulky units already discussed. A product that fits in your hand and that can be installed in less than an hour versus having to crane in a unit taller than you has its advantages. Calibration is quick and simple, and with no moving or rotating mechanical parts to worry about, it becomes very appealing. However, any process where accuracy is required will not benefit from this type of product.

Microwave units can also be used in systems involving gravity-fed solids, dense phase or dilute phase pneumatic conveyors. The microwave solids flowmeters generally look similar to a microwave level sensor.

Capacitive Flowmeters: Simple Installation, lower Accuracy

Capacitive flowmeters have also been on the market for some time. The use of two measuring principles helps increase the accuracy of the total flow measurement, but the device cannot handle higher volumes of material.

Installation is simple and straightforward, as it simply involves removing a section of pipe and installing the flowmeter. Calibration is also easy, but the accuracy is not as good as the large mechanical units.

Capacitive units can be used with gravity-fed or dense phase pneumatic systems and are also a very price-competitive solution compared to the large mechanical devices. The capacitive solids flowmeter is the most similar to a liquid-based meter, as it looks almost exactly like an electromagnetic meter.

Choices, Choices: How to decide?

Selecting the right product will come down to the age-old triple constraint: price, accuracy and fit. If you can afford to spend the money, you don’t have to sacrifice what you need for what you can afford.

Accuracy is based on what is demanded from your process. Fit comes down to how the product will perform with the variables of material density, flow rate, temperature, moisture content, particle size, installation space, pre-feed device, material compatibility. And it’s important not to forget about approvals for hazardous zones!

| Type | Accuracy [%] | Flow rate range [t/h] | Works in gravity-fed flow | Works in pneumatic-fed flow |

|---|---|---|---|---|

| Impact | ± 1 | 0.2 to 900 | Works well | Not recommended |

| Centripedal | ± 0.5 | 1 to 35 | Works well | Not recommended |

| Coriolis | ± 0.5 to 1 | 4 to 600 | Works well | Not recommended |

| Microwave | ± 5 | 0.1 to 20 | Works moderately well | Works moderately well |

| Capacitive | ± 3 to 5 | 20 to 50 | Works moderately well | Works moderately well |

To be an Expert, or not to be an Expert

I have been working with flowmeters for eight years and I consider myself to be well versed. I have colleagues who have been working with this technology for 35 years and they consider themselves to be experienced. However, I have yet to meet anyone who considers himself or herself a flowmeter expert!

There are just so many variables to consider, many of which can change over seasons or even with the daily change in weather. Unfortunately, there are no quick and easy answers. Understanding the application in great detail is a necessity when it comes to applying the right product and options.

My recommendation is to talk to your local supplier and provide him or her with as much information as possible. At Siemens, we provide you with an application questionnaire that asks you to enter all of the required data. We then generate a proposal for the application and also highlight anything that we may wish to investigate further. Our goal is to always ensure the best performance of our products in your application.

Sometimes you just need a Hammer

As I said earlier, solids flowmeters may not be the world’s most amazing piece of technology. However, they are an essential part of many industrial flow applications for the simple reason that nothing else can do their job.

Sure, for your day-to-day home repairs, you could purchase a top-of-the-line nail gun with laser accuracy and power enough to shoot nails hundreds of meters per second. Realistically, though, sometimes you just need a hammer. Similarly, sometimes you just need a solids flowmeter – the right tool for the job.

■