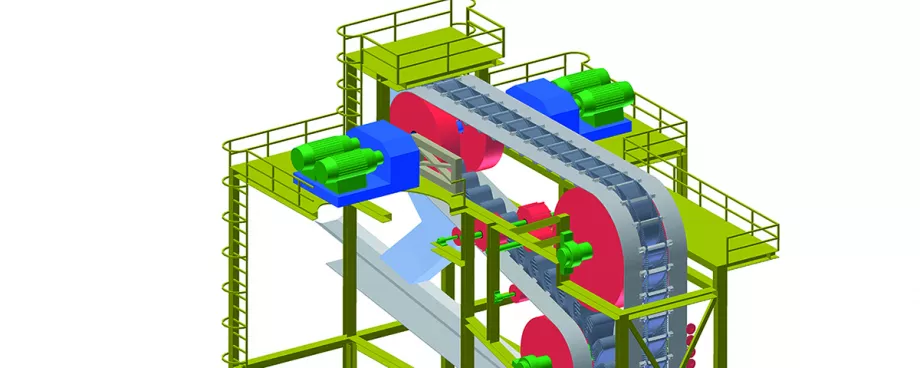

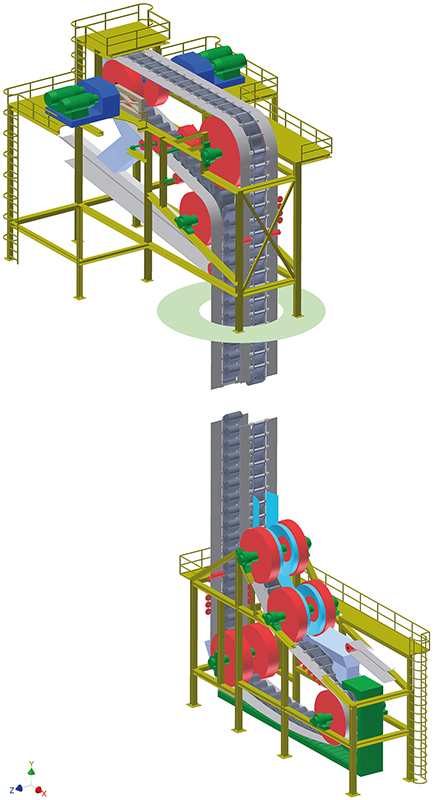

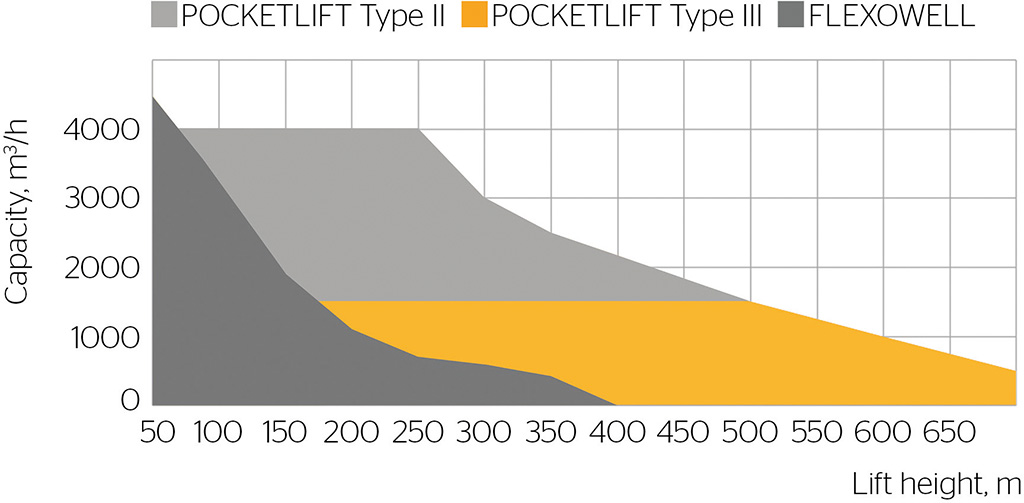

Space-saving, environmentally friend-ly and efficient: This characterizes ContiTech Conveyor Belt Groups Pocketlift. In terms of conveying height and capacity, this conveyor system is supposed to be the most advanced continuous conveying technology for the vertical transportation of bulk materials. With lifting heights of up to 700 meters (2300 feet) and capacities of up to 6000 metric tons per hour, it sets new standards in continuous vertical conveying. As shown at the White County Coal (WCC) mine in Carmi, IL, USA, this system is perfectly fitted for conveying bulk materials in mine shafts, allowing cost-effective and efficient mining operations.WCC was the world’s first mining company to use the trend-setting technology for vertical conveying in its own mine. Even today, it still operates the world’s largest Pocketlift installation. The company chose this system because it helped to double the conveying output in the mine without the need to sink a conveyance shaft with standard dimensions. Instead, the new shaft measures nearly 12 feet in diameter. Consequently new coal deposits could be accessed and transported without making large-scale investments or taking up a lot of space.The company has been using its shaft conveying system for more than a decade now and the technology has proven itself in daily use. Since 2002, the system has transported over 38 million metric tons of coal to the surface and has impressed people with its clear benefits versus a traditional skip hoist system. Whereas such transportation systems are made entirely from steel, this vertical conveyor is much more lightweight, comprising two narrow steel-cord belts connected by rigid triangular cross bars which also have a guiding function. The material is transported in fabric-reinforced rubber pockets bolted to the middle of the cross bars. The pockets can be installed and removed individually. This structure is much more compact than conventional conveyor systems and ideal for handling bulk materials in mining shafts. Thanks to the minimal space required in the vertical section, the system can also be used with very small shaft diameters. “Quite often, even an existing ventilation shaft can be used. This helps to reduce construction costs” says Friedhelm Litz, Innovative Products manager at the Contitech Conveyor Belt Group.

Another advantage for system operators: Pocketlift saves energy and, in turn, money too. Compared with conventional conveying systems, it needs a lower driving power. Skip hoist systems need to accelerate the materials to high speeds which result in power peaks and therefore in higher investments for energy supply. whereas the Pocketlift, due to the continuous mass flow, requires less driving energy. The cost per metric ton of bulk material conveyed are well below the average – energy consumption per metric ton and 100 meters (328 feet) of lift height stays below 0.3 kWh allowing mine operators to save on energy supply. Thanks to low noise emissions, the conveyor system has a very small impact on the environment.Pocketlift is a systematic enhancement of the tried-and-tested Flexowell technology. Flexowell conveyor systems are designed for horizontal, high-incline and vertical transport of bulk materials of all kinds – from coarse coal and ore, rock, granular sand, fertilizer to grain varying from ultra-fine, floury matter to lumps up to 16 inches in size. The advantages for system operators are low space requirements and fewer material transfer points as well as in the lower energy requirement and environmentally friendly handling.

A Success Story is continued

Every Pocketlift is a custom design, specially tailored to the application in question. For WCC, Contitech – in collaboration with its long-standing U.S. partner FKC-Ltd. has created a solution with a lifting height of 276 meters (905 feet). This system transports up to 1815 metric tons per hour. With 782 pockets, the conveyor belt has a total weight of around 100 metric tons and is extremely lightweight compared with conventional shaft conveyor systems. “Thanks to the Pocketlift technology, the head gear of the shaft could be reduced to a minimum,” explains Litz.

Even after more than a decade, WCC is still very pleased with its shaft conveyor technology. The company has already renewed the system after conveying 30.5 million metric tons with the first conveyor belt. Replacing a conveyor belt is a highly complex logistical task and it also entails downtime for the mine, so it is essential that it can be replaced as quickly as possible. Thanks to the easy handling of the Pocketlift-belt and excellent planning, the replacement of the belt in the White County Coal Mine took one week less than originally scheduled.In the meantime, many other mine operators have become aware of the benefits of Pocketlift. In addition to projects already completed in underground gypsum mining in Russia, Contitech is also in discussions with other mine operators around the globe. “The greatest challenge at present is how to transport coal through a height difference of 1000 meters. For this, we are intending to place two Pocketlift systems on top of each other,” says Litz. “And, I’m sure that Pocketlift is up to this challenge”.

A Note from the Editor

For all statements in this article that refer – directly or indirectly – to the time of publication (for example “new”, “now”, “present”, but also expressions such as “patent pending”), please keep in mind that this article was originally published in 2014.

| About the Author | |

| Mario TöpferHead of Technical Media RelationsContiTech AG, Germany |

■