(From the archive of ”bulk solids handling", article published in Vol. 36 (2016) No. 6 , ©2016 bulk-online.com)Belt conveyors are efficient and reliable materials handling systems. A rubber belt with synthetic fabric or a steel cord carcass is typically the most expensive single component of a conveyor. The belt also plays a dominant role in the ownership cost and reliability of a conveyor [1]. While conveyor belts with more than 15 years of service life are not unusual, premature belt failure can also be caused by accidents, engineering or maintenance issues. The top cover, carcass and bottom cover are all subject to premature failure or damage. The top cover usually suffers from damage related to transport material or tramp metal. The belt carcass may suffer from steel cord breakage and carcass penetration. The belt bottom cover is not in contact with transport material, instead the bottom cover is in constant rolling contact with idlers and pulleys. As a result, premature bottom cover failure typically starts from the interaction between the belt and the idlers and pulleys. This paper discusses several scenarios of early belt bottom cover failure.

Cover Failure at Idler Junction

General Analysis

The conveyor belt bends at the junction between idler rolls. The bending creates compression in the belt’s top cover and tension in the bottom cover. The extent of this deformation depends on the idler arrangement, belt properties and belt loading.High tensile strain in the bottom cover, due to severe bending at the idler junction, can facilitate surface cracks. The surface cracks may develop from short lengths to long stretches and further coalesce to cause deep cover failure. An example of this idler junction failure is illustrated in Fig. 1. Some belt manufacturers’ manuals mention this type of failure, but without detailed analysis [2].

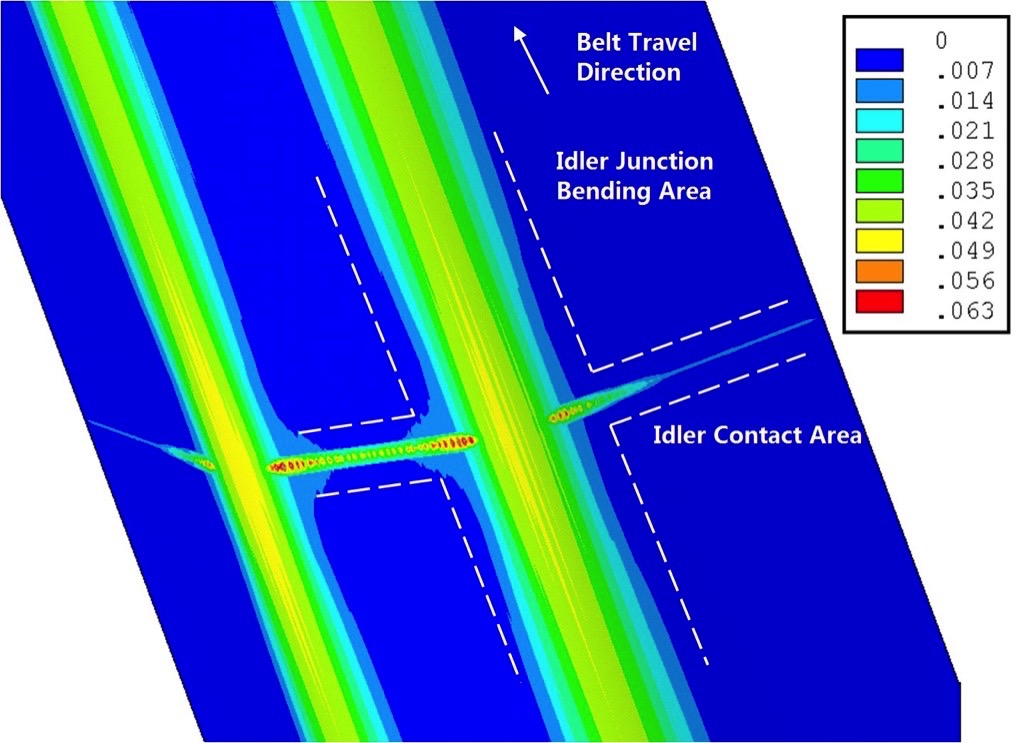

Fig. 2 shows a finite element analysis (FEA) of the deformation in a steel cord belt on three-roll trough (idler set not shown in the figure). The idler junction bending area is along the belt travel direction, symmetric along the belt centre line, and separates the belt’s contact between the centre roll and wing roll.

Deformation in the idler junction area is mainly due to bending. Deformation in the idler contact area is mainly compression from the material and belt load and shear from rolling resistance. The circles in the idler contact area are high pressure points directly under individual steel cords, which relate to a different type of bottom cover failure.Bending at an idler junction is affected by several factors: trough angle; belt thickness; cross-sectional loading of belt; material surcharge angle; idler spacing; and convex and concave curves. Increased bending is characterised by a smaller radius of the bending curvature, and less bending by a larger radius of the bending curvature. The following is a list of the main factors that influence idler junction bending.

- Trough AngleA steep trough angle like 60° increases the bending, compared to a shallow trough angle like 35°.

- Belt ThicknessA thicker belt reduces idler junction bending, as the bending stiffness is augmented.

- Material Cross-Sectional Loading and Idler SpacingThe combined weight of loaded material and belt is heavier than an empty belt. The weight of material is typically the major force and increases the idler junction bending. The bending strain in the idler junction is highest when the belt is right on top of idler rolls. The bending relaxes between idler stations. This relaxation is referred as the belt flexure [3]. By the same token, because idlers provide support to the belt, wide idler spacing increases the idler junction bending.

- Material Surcharge AngleThe material surcharge angle affects the idler junction bending. High angles create a heaped pile of material in the trough belt, which increases the material loading pressure at the middle of the centre roll and reduces the loading pressure around the idler junction and vice versa.

- Vertical CurvesAt vertical convex curves, a component of belt tension is added to the belt weight and material loading in the gravitational direction, pushing the belt against idler rolls, increasing idler junction bending. A concave curve reduces idler junction bending since the vertical component of belt tension is subtracted from the weight load.

- Idler Configuration

Fig. 3: Belt contacting idler edge

Fig. 3: Belt contacting idler edgeIn an inline idler arrangement, where all rolls are on the same plane, there is a gap between adjacent idler rolls. If the gap is wide enough and the belt’s idler junction bending is severe enough, the belt may contact the idler edge. Fig. 3 shows an example of a belt contacting the idler edge. When this scenario occurs, the idler edge acts like a knife edge, where the contact stress between belt and idler edge is very high. This leads to an excessive rate of cover wear. Well designed and manufactured inline idler sets should have an idler gap of less than 10 mm to avoid potential contact with the belt.

An improved design is the offset idler arrangement, where the rolls are staggered to create an overlap at the idler junction. This eliminates any potential contact between belt and idler edge. A large diameter idler roll reduces the contact stress between belt and idler, and the idler junction bending is reduced. For the same belt width, a five-roll trough arrangement reduces the idler junction bending, compared to a deep trough three-roll arrangement, as there are additional idler junctions that reduce the bending angle at each idler junction.The length of an idler roll can affect the idler junction bending. For a typical three-or five-roll trough, the idler length is equal. Non-equal roll lengths are often implemented in overland conveyors [4], one reason being is to change the load distribution between the wing roll and the centre roll to a more optimal level. The material cross-sectional loading capacity is also affected by the length of the idler roll. If the centre roll length is decreased, the idler junction bending increases.

Idler Junction Pressure Index

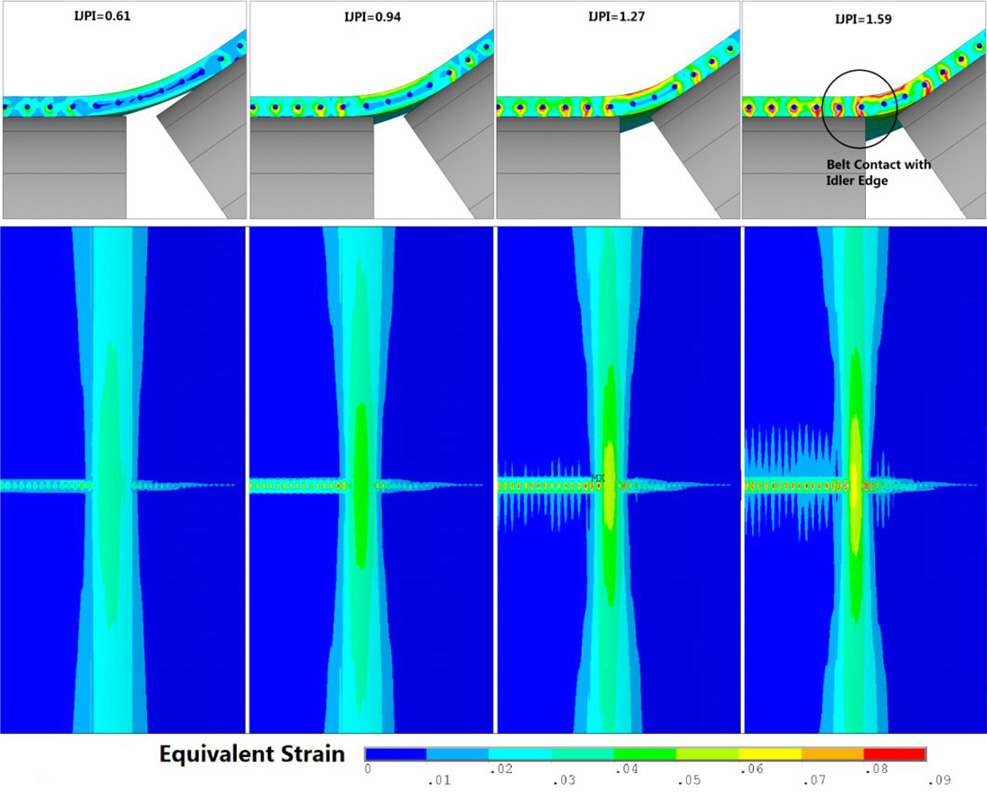

Conveyor Dynamics Inc. (CDI) developed the Idler Junction Pressure Index (IJPI) as a quantitative tool to measure the idler junction bending stress. The IJPI allows the designer to explore various conveyor and belt parameters like idler spacing; diameter; roll lengths; belt speed; belt thickness etc., to reach an optimal design while maintaining allowable idler junction bending. Higher IJPI values mean more bending deformation. As a general design criterion, the IJPI should not exceed 1.0~1.2 range. Fig. 4 shows a finite element model of the idler junction bending in a 1200 mm wide, 13.5 mm thick belt on a 35° degree trough. The material loading can be adjusted to achieve four different IJPI values, from low to high. It is obvious that the strain and idler junction bending increases with a higher IJPI value from 0.61–1.59. IJPI = 1 can be viewed as a relatively conservative limit. When a IJPI exceeds 1.2, the belt bending becomes severe. At IJPI = 1.59, the belt starts to contact the idler edge.

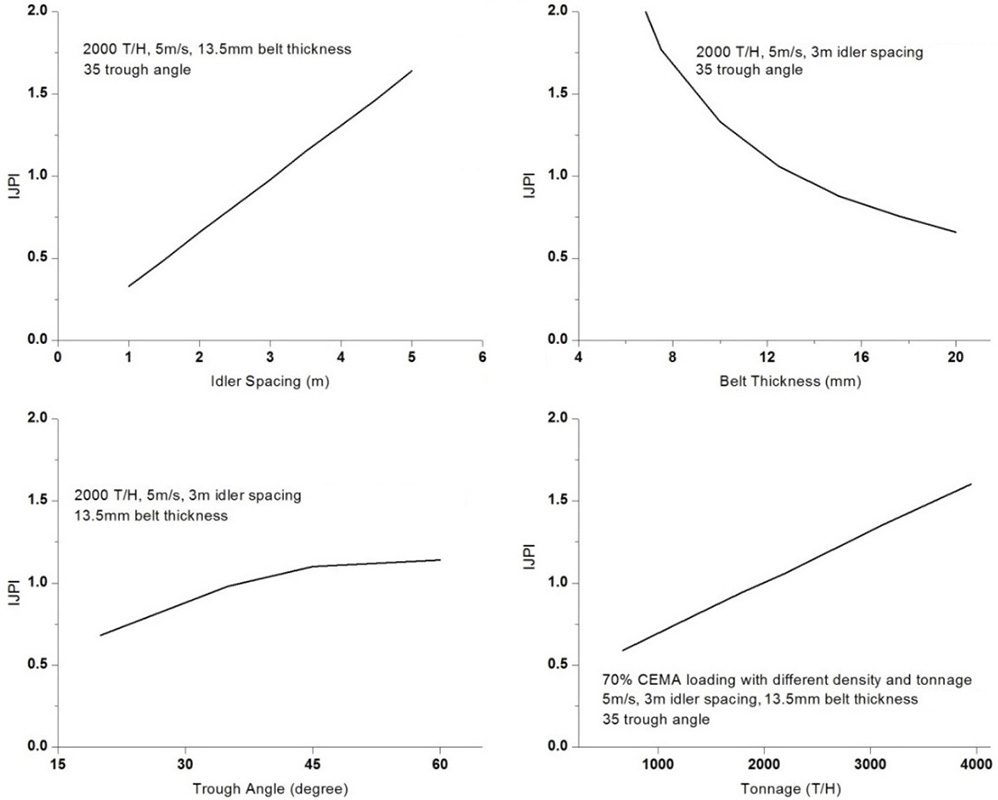

To illustrate the relationship of a IJPI to conveyor and belt parameters, Fig. 5 shows a different IJPI on the same 1200 mm wide belt, at 70% CEMA loading and 5 m/s belt speed, but with varying idler spacing, belt thickness, trough angle and tonnage. Some weight related factors, like idler spacing and tonnage, show a linear relation to the IJPI. Some bending related factors, like belt thickness and trough angle, show a non- linear relation to the IJPI. For example, the IJPI increases beyond a linear relationship with reduced belt thickness.

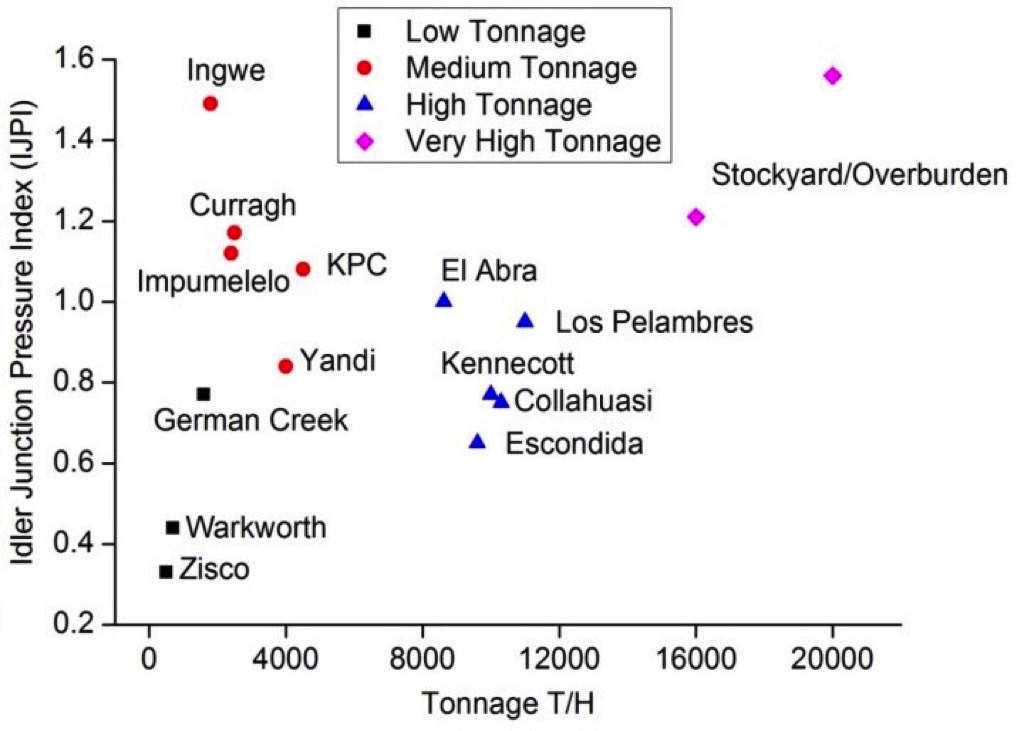

The design limit on a IJPI is derived from studying belt behaviour and service life on running conveyors. A high IJPI should be mitigated by design changes like reducing idler spacing, increasing belt thickness or increasing belt speed. Fig. 6 displays the IJPI of selected overland conveyor projects that CDI has worked on. Major system details of these conveyors are listed in Table 1.

| Project Name | IJPI | Tonnage[t/h] | Belt Speed[m/s] | Belt Width[mm] | Belt Thickness[mm] | Trough Angle[°] | Idler Spacing[m] | Conveying. Length[km] |

| Zisco(Iron Ore) | 0.33 | 500 | 4.5 | 750 | 14 | 25 | 5 | 15.6 |

| Yandi(Iron Ore) | 0.84 | 4000 | 5.5 | 1200 | 19 | 45 | 2.5 | 4 |

| Impumelelo(Coal) | 1.12 | 2400 | 6.5 | 1200 | 17 | 45 | 4.5 | 27 |

| Curragh(Coal) | 1.17 | 2500 | 7.5 | 1200 | 16 | 45 | 5 | 20 |

| Ingwe(Coal) | 1.49 | 1800 | 5 | 1050 | 14 | 45 | 4.5 | 8.9 |

| Los Pelambres(Copper Ore) | 0.95 | 11000 | 7 | 1800 | 42 | 30 | 1.5 | 12.8 |

| Escondida CV 102(Copper Ore) | 0.65 | - | 6.1 | 1600 | 36 | 35 | 1.5 | 3.8 |

| Overburden | 1.56 | 20000 | 3.15 | 2800 | 28 | 35 | 1 | 1…3 |

Some conveyors may have undergone modifications or upgrades, thus the parameters may not be current. There are four categories of conveyors: first is low tonnage conveyors (<1000 t/h). Due to the low tonnage, the IJPI is low as well, even with a thin belt and extended idler spacing at 5 m.The second category is medium tonnage conveyors between 1500 t/h and 4000 t/h. Conveyors in this category can have a wide range of IJPIs. This is due to the wide variations in system parameters like belt rating, idler spacing, belt speed, etc. For conventional conveyor design using short idler spacing, the IJPI is expected to be low. Conveyor design can also be optimised to reduce capital and operating cost, including reducing belt thickness and width, increasing belt speed and idler spacing, and utilizing a low rolling resistance belt to reduce power consumption. The IJPI is typically increased in an optimised conveyor design, compared to the conventional design with reduced idler spacing. It is the conveyor designer’s responsibility to make sure the IJPI is within the allowable limit.The third category is high tonnage overland conveyors which are operating in some South American copper mines. Although the tonnage is high, over 8000 t/h, the belt thickness is also normally increased by having large diameter steel cords and thicker belt cover to compensate for high belt rating and hard rock handling. Short idler spacing is usually specified to limit idler load and bearing size. For these conveyors, the IJPI is generally expected to be within design limits, until the belt becomes thin from significant cover wear.The fourth and final category is very high tonnage conveyors over 15000 t/h. This type of conveyor is located in large stockyards in bulk material handling ports or surface mining operations. They do not necessarily have long lengths or a high incline/decline angle, but are characterised by wide belt and very high tonnage. The IJPI can increase very quickly with a normal three-roll trough even with reduced idler spacing. Careful consideration of idler spacing and trough arrangement should be taken to limit the idler junction bending.

Accelerated Cover Wear from sliding Friction and high Normal / Shear Stress

In Fig. 2, the idler contact area shows high deformation areas (circles) lying under individual steel cords. The contact pressure is relaxed under the rubber gap between adjacent steel cords. Also, the contact pressure near the edge of the wing roll and centre roll is higher than the rest. Combining the two effects, the localized contact stress can be significantly higher than the average contact stress over the entire contact area.The contact stress is composed of shear and normal stress. The shear stress is originates from indentation rolling resistance. The normal stress comes from the belt and material weight. In addition, convex curves, whether created intentionally to change the belt direction or unintentionally by idler misalignment, apply part of the belt tension as a vertical load on the idler to further increase the normal contact stress and deformation. For a typical three-roll trough configuration, the pressure on the centre idler roll is higher than that on the wing roll.High normal and shear stress can potentially cause accelerated belt cover wear. One example is shown in Fig. 7. This particular belt was travelling at high speed with a heavy material load, so both normal and shear contact stress was high. The contact stress further increased around the idler edges and directly under individual steel cords. In Fig. 7, the spacing of the circular damage spots matches the spacing of steel cords in the belt, which is exactly the high stress area. If the bottom cover rubber’s mechanical property is not strong enough to withstand the stress or strain level, premature bottom cover belt failure will occur.

Tilting the idler arrangement forwards is adopted as a solution or precaution against belt mistracking. The rotational velocity of a tilted wing roll is at an angle (tilt angle) against the belt travel direction. The linear velocity of a wing roll can be separated into two components: one parallel to the belt travel, and the other aligned with the belt travel direction. The velocity component parallel to the belt travel is a rolling contact, which has very minimal wear on the belt. The velocity component, aligned with the belt travel direction, is a sliding contact. The sliding frictional force pushes the belt down and stabilizes it.However, the sliding friction also creates additional wear on the belt bottom cover in the wing roll contact area. By the same argument, backward tilting is not used because the direction of the frictional force is pulling the belt upward from both wing rolls, which leads to more belt mistracking. Fig. 8 shows the belt cover wear caused by the forward tilting of the wing roll.

The forward tilting of wing rolls can wear the belt bottom cover down to the steel cords. The high wear area also corresponds to the high contact stress area on the wing roll near the idler junction. The cover wear on the centre roll and belt edge area is much less pronounced. For short plant conveyors, belt cycle time is short and the belt top cover tends to wear very quickly. If belt mistracking creates frequent unplanned conveyor shutdowns, it is advantageous to use the forward tilting of idler wing rolls to improve belt tracking. However, such practice should be avoided for overland conveyors, when belt mistracking should be prevented by proper idler arrangement and good installation accuracy.

Cover Damage from Ceramic Pulley Lagging

Ceramic pulley laggings are chosen over rubber pulley laggings for their superior wear resistance and higher friction coefficient. Manufacturers provide different types of ceramic lagging tile designs. Certain ceramic lagging is designed to provide a greater friction coefficient between the belt and pulley, usually by introducing small, sharp-edged protrusions on the lagging surface. The protrusions are intended to penetrate into the belt bottom cover and provide greater resistance against the slipping motion of the belt. However, from analysis of classic contact mechanics [5], it is known that on a drive pulley, certain slipping is intrinsic to the interaction between belt and pulley. Aggressive ceramic lagging design, in combination with high tension ratio on a drive pulley, can potentially cause premature belt cover failure.Fig. 9 shows the wear marks on the belt bottom cover produced from ceramic lagging tiles, where the spacing of the white stripes (wear marks) match exactly the spacing of the ceramic lagging tiles. The abrasive wear on the belt cover can be identified in the lower left image. Ceramic lagging tile design affects the contact stress.

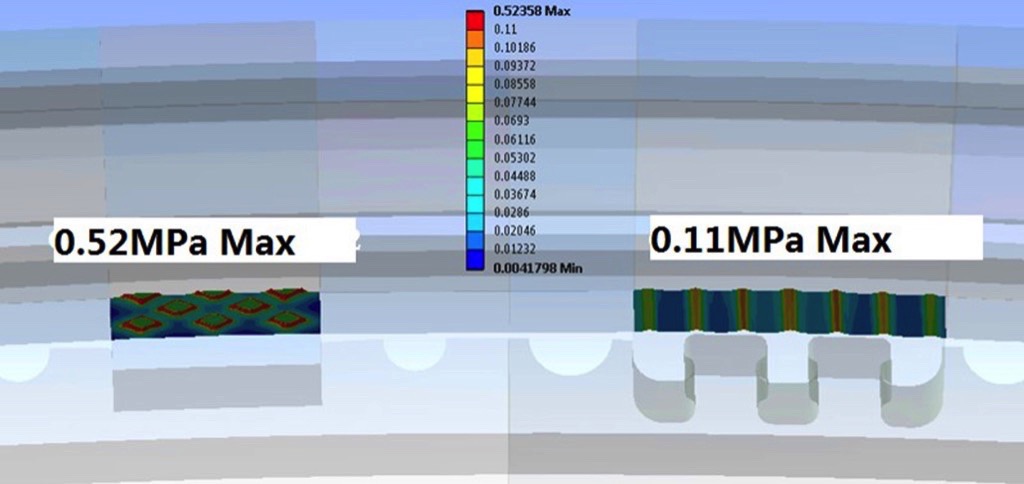

Fig. 10 shows two different ceramic lagging tiles: the left lagging tile has sharp protrusions and the right lagging tile has a wavy surface. Under the same contact condition (belt tension and pulley diameter), the contact stress is more than four times higher on the lagging tiles with sharp protrusions. Indeed, the higher contact stress can provide more ‘grip’ between the belt and pulley, but can also add to the possibility of belt cover damage.

Ceramic lagging tiles may dislodge from the pulley. Missing laggings create an irregular pulley surface. Sharp corners and edges of existing lagging tiles that are adjacent to the missing pieces are exposed to contact with the belt cover and lead to accelerated wear.

Fig. 11 shows such an example: the belt cover has a wear zone near the centre of the belt down to the steel cords, the location of which matches that of the missing lagging tiles on the pulley surface. Although a few missing lagging tiles may seem insignificant, the related belt damage may quickly escalate to a serious level in which the entire belt needs to be replaced. The wear is caused by localised cover rubber slip over the edges of ceramic tiles due to relaxation, between the lagged region and the region with missing tiles. Good inspection and maintenance practices are essential in preventing such belt damage.

Conclusion

Premature belt bottom cover failure is caused by improper contact behaviour between the belt and idlers or pulleys. The physical properties of cover rubber can certainly be enhanced to reduce cover wear, but good engineering and maintenance practices are also essential to prevent accelerated bottom cover wear.Idler junction failure is caused by excessive bending at the idler junction area, or direct contact with the idler edge. The idler junction bending is related to conveyor and belt parameters: trough angle; belt thickness; material cross sectional loading; idler spacing; material surcharge angle; vertical curves; and idler configuration. The idler junction pressure index indicates whether the idler junction bending has become excessive.High normal stress from heavy load and convex curves and high shear stress from high rolling resistance and belt speed can lead to early cover failure, especially near the boundaries of the contact area on wing rolls and the centre roll, where the contact stress is at its maximum. A forward tilting idler roll accelerates the cover wear by introducing sliding friction between the belt and wing rolls.Ceramic lagging tiles with sharp protrusions can cause local high contact stress and increase bottom cover wear. Good maintenance is required to locate and fix missing ceramic lagging tiles on the pulley surface to prevent belt cover damage.

Acknowledgements:

1. The author would like to thank the excellent team at Veyance Technologies Inc. for their support and collaboration, and ELB Engineering Services Limited for their initiative and coordination in bringing this paper to the Beltcon 18 Conference.2. This article is based on a presentation of the author during Belton 18, 5./6. August 2015 in Johannesburg, South Africa.

References:

- Nordell, L.: Overland conveyors designed for efficient cost and performance. Beltcon 12, Johannesburg, South Africa, 2003. IMHC.

- Veyance Technologies Inc.: Installation, maintenance and troubleshooting guide. Goodyear Engineered Products.

- Wheeler, C., Roberts, A., Jones, M.: Calculating the flexure resistance of bulk solids transported on belt conveyors. Particle and Particle Systems Characterization, Vol. 21 (2004), Is. 4.

- Steven, R.: Belting the world’s longest single flight conventional conveyor. Bulk Solids Handling, Vol.28 (2008), No.3.

- Johnson, K.L.: Contact Mechanics. Cambridge University Press (2003).

| About the Authors | |

| Yijun ZhangConveyor Dynamics, Inc., USA |

■