(From the archive of ”bulk solids handling", article published in Vol. 32 (2012) No. 1 , ©2012 bulk-online.com)Located at over 4000 metres above sea level in the Altiplano of the Andes Mountains, the San Cristobal Mine is the largest mine in Bolivia. The open-pit silver, lead and zinc mine's production process requires the transportation of 150,000 tonnes of rock, and the processing of 40,000 tonnes of mineral daily.In early 2010, Bolivian contractor Carlos Caballero responded to a bid request for a stockpile containment solution. Minera San Cristobal, in accordance with its principles regarding worker protection and protection of the environment and neighbouring communities, sought to prevent the release of dust from its stockpile into the environment, and protect the material awaiting transport to the mine's ore processing facility.

| Project Details | |

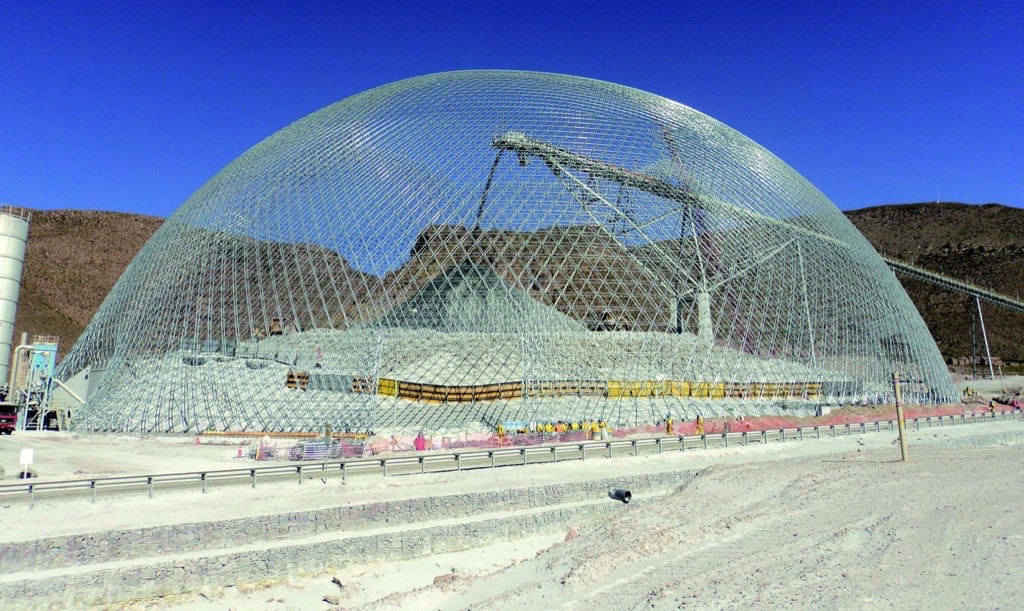

San Cristobal Mine Storage Dome

|

|

Caballero teamed with global storage company Geometrica to propose a customized containment solution for the mine. Following review of the proposal and visits to other bulk storage domes in South America by San Cristobal engineers, the project was awarded to the Caballero-Geometrica team. Caballero served as the main contractor and installer of the dome, while Geometrica, as a subcontractor, engineered, manufactured and supplied the dome. Key factors in the decision to employ this type of dome solution for the site included the team's extensive experience, the capability to build around an operating stockpile, and the capability to follow an irregular shape for the supports.

South American Record

The finished stockpile containment structure is a dome 140 metres in diameter and 59 metres in height anchored by concrete foundation – the largest dome of its kind in South America. The foundation, which accommodates a nine metre change in elevation over 140 metres, is fitted to the terrain. The dome is designed to withstand wind speeds of up to 150 kilometres per hour and an ice load of 110 kilogrammes per squaremetre.The Geometrica dome at San Cristobal Mine is made up of more than 88,000 galvanized steel tubes organized and inserted into aluminium hubs to form the structure. Local crews recruited by Caballero built the dome as deliveries arrived on site. Shipments consisted of containerised crates of parts, each holding two tonnes of structure, and organized by construction phase. The system requires no welding, as the prefabricated tubes slide easily into the aluminium hubs and hold fast. The precise yet simple assembly process allowed the mine to continue to operate in the midst of dome construction and made it easier to assemble the building in an environment subject to high winds.

Technical Details

A ventilation lantern is located at the top of the dome and additional armature on the side of the dome can support dust removal equipment. The interior includes a system for lowering the material-conveyor pulley for maintenance, and a catwalk circling the dome interior. Three 13×10 metre doors allow simultaneous access by up to two off-road vehicles to the interior of the dome. The finished building is clad in galvanized and painted metal sheets and translucent skylights provide natural light. Material is transported from the dome to the mine's ore processing plant via an existing underground tunnel.Geometrical and technical details of the storage solution include:

- Covered area: 15,493 square metres

- Surface area: 25,340 square metres

- Base diameter: 143 metres

- Height from base to apex: 59 metres

- Weight of structural dome elements: 523,400 kilogrammes

- Structural material: galvanized steel and aluminium

- Number of tubes: 88,329 pieces

- Number of connectors: 25,295 pieces

- Cladding: galvanized steel, painted steel and translucent panels

Worldwide Applications

In addition to creating the largest bulk storage dome in South America at the San Cristobal Mine, Geometrica has designed more than 15 bulk storage domes for mining projects located in the Andes, where construction challenges include rugged terrain, remote job sites and insanely high snow loads. Examples of recent projects include the Barrick Zaldivar Mine, the Mantos Blancos coppermine, both located in neighboring Chile, as well as Minera Aguas Tenidas in Spain. Hundreds of Geometrica structures have been built for clients and endusers around the world including BHP Billiton, Anglo-American, Barrick, Codelco, First Quantum, Fluor, Sumitomo, and other mining companies in locations ranging from the Sahara desert to the jungles of Borneo.Apart from the solutions for irregular shapes, the company offers containment solutions for automated, ring-shaped stockpiles and for spans of up to 300 metres. A precise design process, the ability to package and ship a complete structure by construction phase, and mechanical joints that do not require welding result in a durable structure that is easily built in a wide range of environments.

A Note from the Editor

For all statements in this article that refer – directly or indirectly – to the time of publication (for example “new”, “now”, “present”, but also expressions such as “patent pending”), please keep in mind that this article was originally published in 2012.

| About the Author | |

| G. MendezAdministrative ManagerGeometrica, Inc., USA |

■