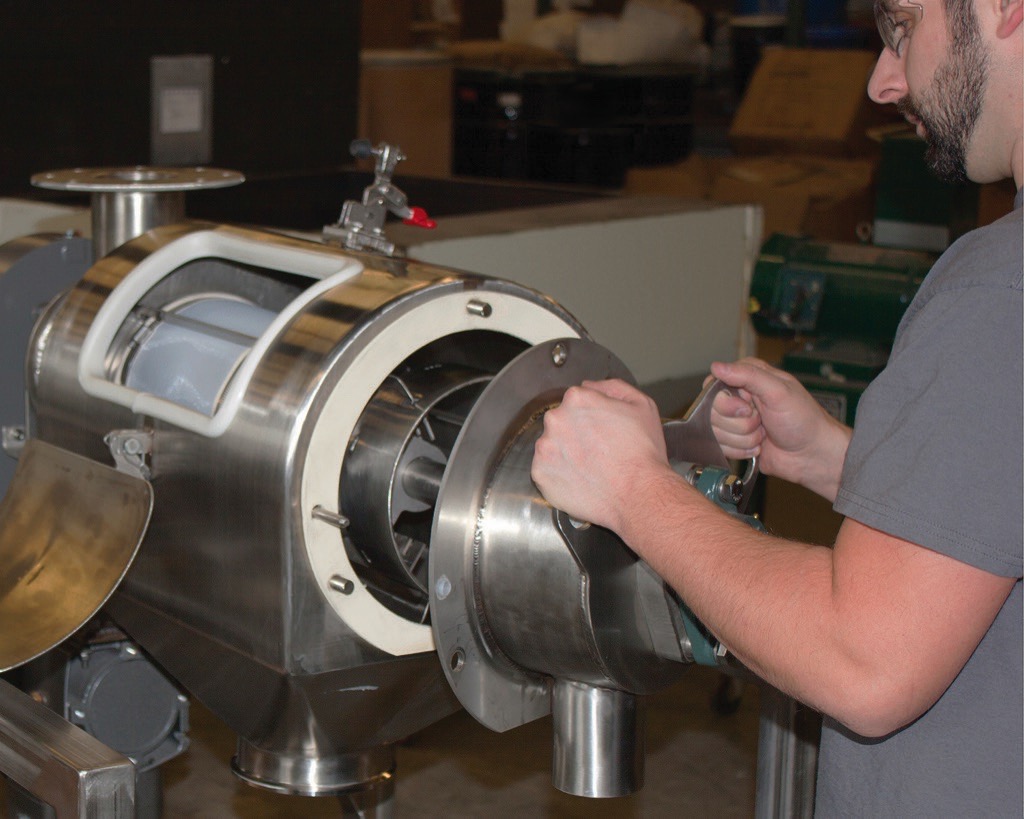

The clean, simple design features external bearings at both shaft ends which can be lubricated through external fittings. The bearing at the discharge end of the shaft is mounted on the outside of a discharge housing that can be removed with screw knobs for easy access to change, inspect or clean the screen and paddles. A hinged access door on the side of the housing allows visual inspection.Screens are available in a wide range of apertures to satisfy a diversity of sifting applications across the process and packaging industries. Depending on application, the shaft is driven by a 2.24 kW motor and rotates at approximately 500 rpm, offering vibration-free performance and high throughput rates with little or no product degradation. Constructed of #304 or #316 stainless steel, it is available finished to sanitary or industrial standards.

The sifter is available as a stand-alone unit or paired with any of the company's size reduction equipment including: lump breakers, screen classifying cutters, pin mills, attrition mills, rotary knife cutters, hammer mills and shredders; or mixing/blending equipment including ribbon/paddle/plow blenders, rotary batch mixers, rotary continuous mixers, fluidised bed mixers and variable intensity blenders. ■