Product News

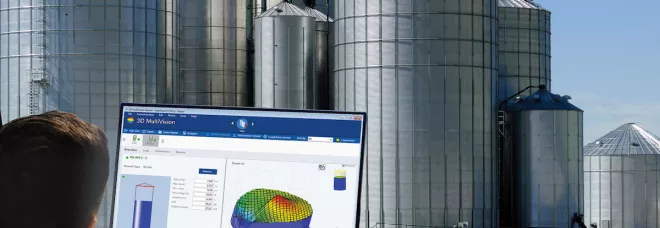

Binmaster 3D Level Scanner IECEx/ATEX approved for Global Market

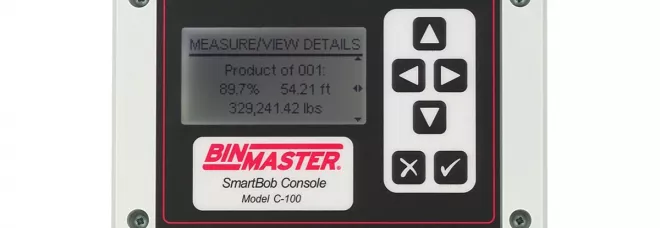

Lincoln (NE), United States – Accurate 3D level measurement for silos is in global demand. BinMaster answers with the launch of the 3D Level Scanner with IECEx/ATEX approvals opening world-wide possibilities for tough applications. BinMaster is the exclusive worldwide provider of this level sensor with multiple-point measurement…read more