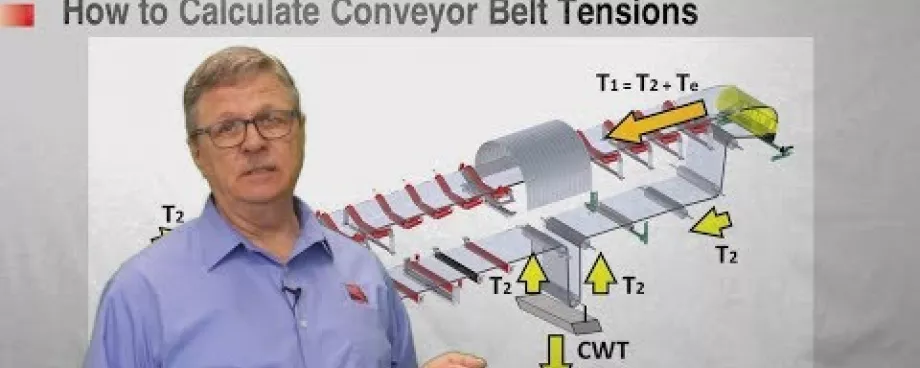

Common components on a typical bulk handling belt conveyor include head pulley, snub pulley, flat belt, tail pulley, carrying idlers, return idlers, belt plow, counterweighted take-up, belt cleaner, loading skirts, hopper feeder, and slider bed.

The CEMA Conveyor Design Manual provides this (historical method) equation to calculate effective belt tension.

Te = LKt (Kx + KyWb + 0.015Wb) + Wm(LKy + H) + Tp + Tam + Tac

These parameters enable the designer to calculate belt tension required to overcome:

- Friction

- Gravity

- Momentum

Some Friction components are:

- Tbc, the tension required to overcome belt cleaner drag

- Tsb, the tension required overcome skirt board drag

- Tyr, the tension required to overcome friction in the bearings of the return rollers as the empty belt travels over the return strand.

Gravity components include:

- Tb, the tension required to lift or lower the conveyor belt;

- Tm, the tension required to lift or lower material.

The Momentum component, Tam, is the tension required to accelerate the material on the belt from the initial velocity, as it hits the conveyor, to the terminal velocity, which is defined as the conveyor belt speed.

■