Two independently-powered, high speed tulip-shaped intensifiers produce any shear necessary to assist with dispersion.

The unit achieves batch uniformity in ratios to one part per thousand, blends significantly faster than trough-style horizontal mixers, and handles a greater variety of materials, including thinner pastes.

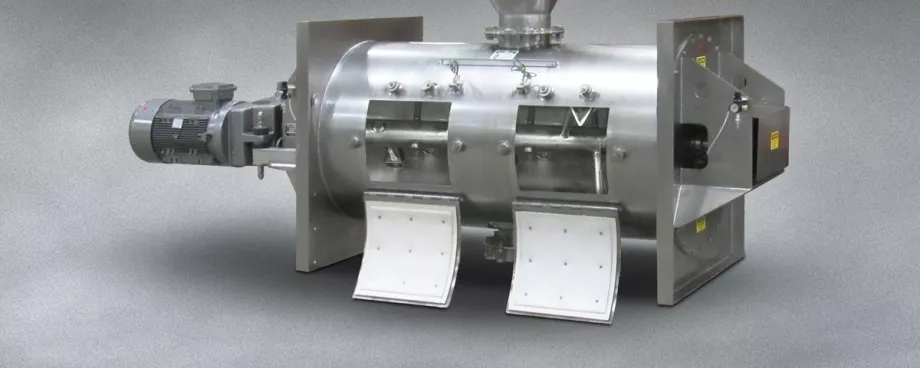

Constructed of #304 or #316 stainless steel and finished to sanitary standards, it is suitable for food, pharmaceutical, chemical, plastics or other applications in which clean-out is important to avoid cross-contamination.

It is equipped as standard with dual access doors on the side, a bottom discharge port, and air purge packing shaft seals. Optional are heating or cooling jackets, injection ports for liquid additions and various discharge and inlet configurations.

■