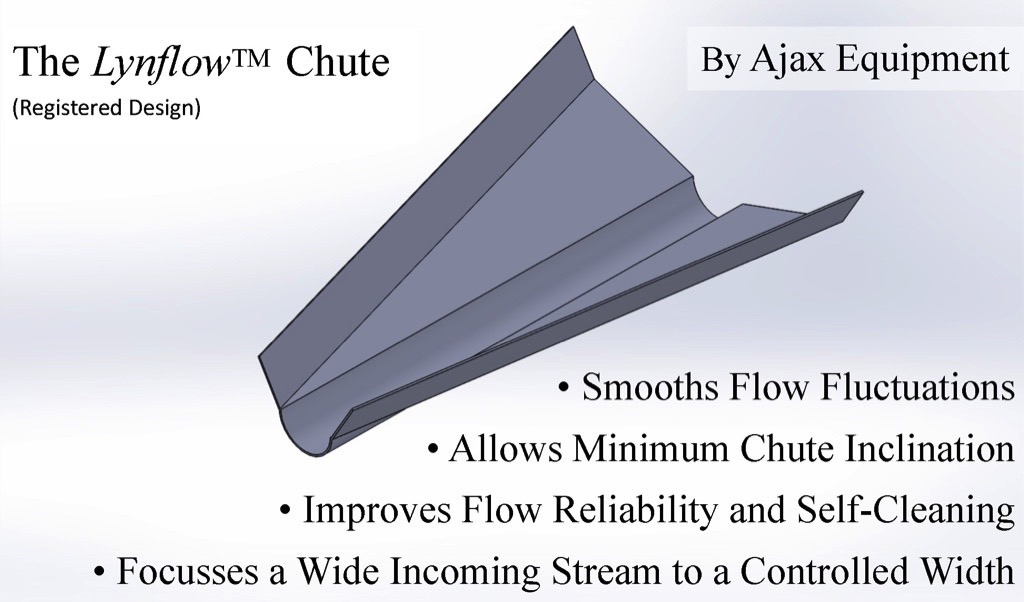

The performance also demanded complete reliability, self-clearing slip, smoothing of the flow irregularities to a steady stream and focussing of the flow to a bed depth of at least 10 mm. At this bed thickness and appropriate flow stream width, the velocity of the flow stream needed to be less than 10 cm/sec, a virtual crawl.A conventional chute with tapered sidewalls focussed the material and slightly attenuated flow variations, but needed to be steep because of friction on the walls and internal shear losses to converge the product, which increased as the width reduced. A flared chute was used to focus the material to a central region. It did this well at an axial inclination less than the conventional chute because the convergence was brought about by the combined angle of the flare and the chute automatically centralised the flow. The chute also smoothed the flow undulations by spreading the surges into the central region over an axial length of the flow stream. However, whereas this formed a deeper central bed, the bed depth tailed off to a ‘feather’ thickness at each side that tended not to self-clear.The addition of a central trough transformed the performance of the chute. All the flowing material was focussed into a bed of uniform thickness and controlled width that was optimum for the detection device. Supply surges were spread out to differing axial locations in the central trough to smooth out irregularities of input. The combination of the flared surfaces with the chute inclination improved slip on the side surfaces and material in the deep central secured reliable flow at a lower inclination and slower flow velocity than was otherwise possible. The design was registered and forms part of the LynflowTM innovative designs of equipment that is marketed by Ajax Equipment. These chutes are custom made, based on the measure physical properties of the bulk material and the contact surface to suit the specific application. They can be made at any scale and optimum material of construction for the duty.In summary, LynflowTM chutes:

The performance also demanded complete reliability, self-clearing slip, smoothing of the flow irregularities to a steady stream and focussing of the flow to a bed depth of at least 10 mm. At this bed thickness and appropriate flow stream width, the velocity of the flow stream needed to be less than 10 cm/sec, a virtual crawl.A conventional chute with tapered sidewalls focussed the material and slightly attenuated flow variations, but needed to be steep because of friction on the walls and internal shear losses to converge the product, which increased as the width reduced. A flared chute was used to focus the material to a central region. It did this well at an axial inclination less than the conventional chute because the convergence was brought about by the combined angle of the flare and the chute automatically centralised the flow. The chute also smoothed the flow undulations by spreading the surges into the central region over an axial length of the flow stream. However, whereas this formed a deeper central bed, the bed depth tailed off to a ‘feather’ thickness at each side that tended not to self-clear.The addition of a central trough transformed the performance of the chute. All the flowing material was focussed into a bed of uniform thickness and controlled width that was optimum for the detection device. Supply surges were spread out to differing axial locations in the central trough to smooth out irregularities of input. The combination of the flared surfaces with the chute inclination improved slip on the side surfaces and material in the deep central secured reliable flow at a lower inclination and slower flow velocity than was otherwise possible. The design was registered and forms part of the LynflowTM innovative designs of equipment that is marketed by Ajax Equipment. These chutes are custom made, based on the measure physical properties of the bulk material and the contact surface to suit the specific application. They can be made at any scale and optimum material of construction for the duty.In summary, LynflowTM chutes:

- Focus a wide incoming flow stream to a controlled width or optimum depth.

- Improves flow reliability and self-clearing.

- Smooths inflow irregularities.

- Allows minimum chute inclination for reliable flow and self-clearing.

■