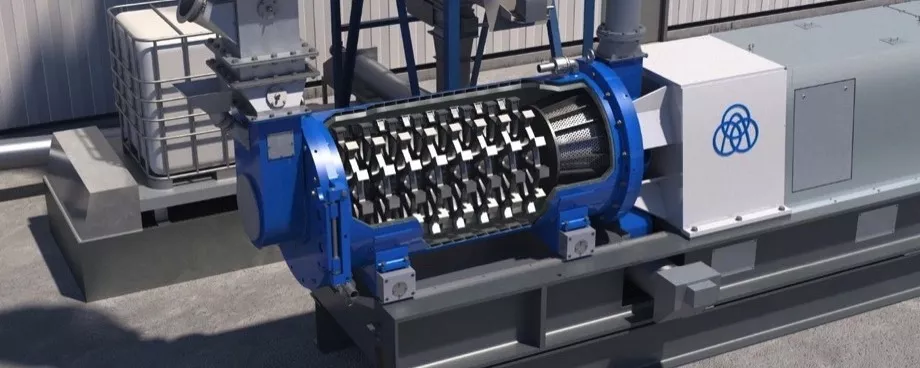

The primary purpose of the booster mill is to improve the clinker reactivity by generating a higher fraction of fines in the product. The system includes the polysius® booster mill and its ancillary equipment including material handling equipment, process gas management and the machine protection system (MPS). thyssenkrupp Polysius will also provide site services and technical support for optimization and maintenance for a duration of 2 years. Equipment deliveries are scheduled through late summer 2023 for a startup anticipated in the Fall 2023.

Xenia Schulze Bernd, Head of Innolab, considers polysius® booster mill as an enabler of existing cement grinding plants and concrete plants for clinker factor reduction. “As a full-range supplier for the cement and lime industries, our expertise covers all mill types. The aim is to support our customers in the long term and locally, starting with an audit of existing plants and a proposal for the optimum solution based on the future cement portfolio and targeted capacity increase. The polysius® booster mill is part of our comprehensive portfolio of services and digital solutions, alongside classifier upgrades, other mill types or spare parts only. We accompany the cement producer from the idea to the cement production. The unique opportunity to produce cements with our pilot mills enable our customers to prove the cement quality before investing."

Project Manager Matthew Burchfield adds: "This is a very important and interesting project for thyssenkrupp Polysius. This is the first booster mill system sold in the United States and one of the first Booster Mills worldwide. We are tasked with a very tight engineering and supply schedule. thyssenkrupp Polysius is working closely with Mountain Cement and their engineering teams. We look forward to a successful project.“

Cesar Millan, VP of Operations at Mountain Cement comments: “Mountain Cement is always seeking opportunities to reliably serve both our long-standing and new customer relationships. This project will allow us to do so by upgrading our facility’s efficiency and long-term sustainability, as well as further enabling our transition to Portland Limestone Cement. We look forward to partnering with Polysius in the successful implementation of this project.

Mountain Cement, located two miles south of Laramie, is Wyoming's only producing site of Portland Cement. The original plant was constructed by Monolith Portland Cement Company in 1927. Upgrades in both capacity and technology have been continuously made throughout the years making Mountain Cement an industry leader in process efficiency, product quality and environmental controls.

■