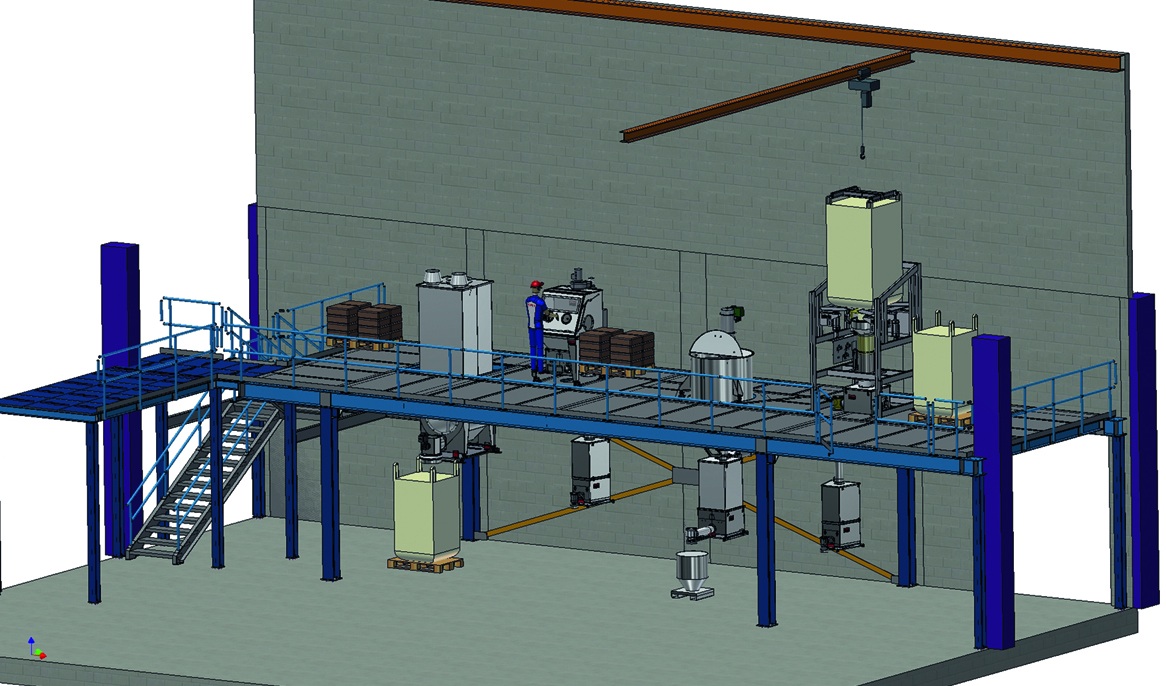

Simulation of the entire processThe reason for this radical change is the new feeder filling level and a 2-tonne overhead crane which can lift standard packaging like big bags, silos, drums and sacks. Overall there are four full test lines available but the Technical Center also provides space for smaller tests that do not require use of the filling level. In addition, there is a separate area with the hygienic conditions required for food and pharmaceutical applications. Continuous processes are the most common test requested, but batching applications can also be tested on a large and small scale in the Technical Center. “Batching is very interesting for high-precision applications,” Horst Vohwinkel explains. The new facilities enable engineers to conduct precision feeding tests during all phases of the feeding process thereby eliminating risk.“These new facilities enable us to make much better use of our resources. The individual testing lines can be retooled independently, which gives everybody extra time resources to play with“, the CEO stresses. Now that the entire process can be simulated, that gives customers added peace of mind, as they can test their projects in practice on a much larger scale.Some devices require feeding testsThe Duisburg facility provides testing opportunities that many customers can appreciate. As feeders have the capability to work with a wide range of different materials and feature many configuration options, testing is essential to some extent. “Our new FiberXpert fiber feeder is a very good example of this”, Horst Vohwinkel states. “It is compatible with a range of very different materials, but also needs to be specially adapted in each case.”The engineers at Brabender Technologie are convinced that the new facilities will be well utilized. Therefore, staff will be increased at the Technical Center to assist in achieving quicker lead times. Yet it’s not just customers and their processes that benefit. The company will now be able to devote more resources to its own research and development efforts with the extra time saved. Horst Vohwinkel therefore expects faster development lead times for product innovations and enhancements in the future.

Continuous processes are the most common test requested, but batching applications can also be tested on a large and small scale in the Technical Center. “Batching is very interesting for high-precision applications,” Horst Vohwinkel explains. The new facilities enable engineers to conduct precision feeding tests during all phases of the feeding process thereby eliminating risk.“These new facilities enable us to make much better use of our resources. The individual testing lines can be retooled independently, which gives everybody extra time resources to play with“, the CEO stresses. Now that the entire process can be simulated, that gives customers added peace of mind, as they can test their projects in practice on a much larger scale.Some devices require feeding testsThe Duisburg facility provides testing opportunities that many customers can appreciate. As feeders have the capability to work with a wide range of different materials and feature many configuration options, testing is essential to some extent. “Our new FiberXpert fiber feeder is a very good example of this”, Horst Vohwinkel states. “It is compatible with a range of very different materials, but also needs to be specially adapted in each case.”The engineers at Brabender Technologie are convinced that the new facilities will be well utilized. Therefore, staff will be increased at the Technical Center to assist in achieving quicker lead times. Yet it’s not just customers and their processes that benefit. The company will now be able to devote more resources to its own research and development efforts with the extra time saved. Horst Vohwinkel therefore expects faster development lead times for product innovations and enhancements in the future. Connecting customers onlineIn the Industry 4.0 era those responsible for the new Technical Center have not made any compromises in terms of networking – of course in compliance with data security requirements and non-disclosure agreements. All test results are shared with colleagues in Canada and China, where the same testing and analysis software are run. Customers can attend tests either via an online connection or in person.In the new building staff and customers have a direct view of “their” tests from the new meeting rooms. Windows overlooking the Technical Center make this possible. The experts can obtain privacy in these rooms to have meetings and discuss test results.“The new Technical Center is in many respects all about gains – our customers gain peace of mind and we gain a convenient, comfortable working environment. We are thus embarking on a new era of testing and experimentation at Brabender Technologie “, says Horst Vohwinkel in summary.Brabender Technologie is showcasing solutions for the plastics industry in Hall A6 – Booth A6-6213 at FAKUMA in Friedrichshafen, Germany, from October 17 to 21, 2017. ■

Connecting customers onlineIn the Industry 4.0 era those responsible for the new Technical Center have not made any compromises in terms of networking – of course in compliance with data security requirements and non-disclosure agreements. All test results are shared with colleagues in Canada and China, where the same testing and analysis software are run. Customers can attend tests either via an online connection or in person.In the new building staff and customers have a direct view of “their” tests from the new meeting rooms. Windows overlooking the Technical Center make this possible. The experts can obtain privacy in these rooms to have meetings and discuss test results.“The new Technical Center is in many respects all about gains – our customers gain peace of mind and we gain a convenient, comfortable working environment. We are thus embarking on a new era of testing and experimentation at Brabender Technologie “, says Horst Vohwinkel in summary.Brabender Technologie is showcasing solutions for the plastics industry in Hall A6 – Booth A6-6213 at FAKUMA in Friedrichshafen, Germany, from October 17 to 21, 2017. ■

Company News

Brabender Technology at FAKUMA 2017

Duisburg, Germany –