Hazemag Crushing Plant

Because of the high percentage of fines in the feed material, a HAZEMAG wobbler feeder has been installed upstream of the impact crusher to screen off the <60 mm material prior to the crushing process. This reduces the demands on the crusher and also eliminates abrasive fines from the crusher feed. The screening surface of the wobbler feeder comprises a number of rotating shafts spaced at defined intervals, through which spaces the fines can pass. Fitted onto the shafts are discs sized appropriate to the desired separation point. These discs are of triangular shape which support the conveying process and prevent jamming. For this particular application, a two-section feeder design was chosen, with a step in the direction of material flow (see Fig. 2), thus promoting the agitation and breaking up of the material and consequently improving the screening performance of the machine even further. The drive is effected via a central shaft which transfers power to the individual shafts. Each shaft is connected to its neighbour by roller chain, thereby ensuring synchronised shaft running. The drive is reversible, so that potential blockages can be cleared by changing the direction of rotation. Fitted underneath the shafts are rugged scrapers to eliminate possible clogging material. The side walls are fitted with replaceable wear liners.

The crushing operation is effected by one of HAZEMAG’s well-proven impact crushers, an AP-PMH 1615, which in addition to its rugged GSK-type rotor is distinguished by the hydraulically-actuated impact apron adjusting system which ensures that the aprons are retained in their set position during operation. On overloading or entry of tramp metal, the aprons can retract in a controlled manner, and then immediately return to their prescribed setting position. Thanks to this hydraulic system, a high degree of operational safety is maintained with a consistent product quality. Another feature worthy of mention is the hydraulically-actuated inlet chute plate; should an excessively-sized rock be wrongly fed to the crusher and become jammed in the inlet, the chute plate can be moved at the push of a button and with simultaneous raising of the impact plates, the offending rock released into the crusher. Such a device is particularly valued by plant operators because of its simplicity of operation and quick solution to the problem.

The capacity of the plant is 420 t/h, with approx. 100 t/h being removed by the pre-screening operation and by-passing the crusher. The whole project was designed by HAZEMAG & EPR GmbH, who also supplied the mechanical equipment. All the steel structures, etc. were supplied by an Italian company, Metalmec Sud of Barletta. The plant was recently put into operation, and not only represents a modern concept with state of the art technology, but is also distinguished by its advanced design.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8845-hazemag-group.htm" target="blank">https://edir.bulk-online.com/profile...emag-group.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=HAZEMAG+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

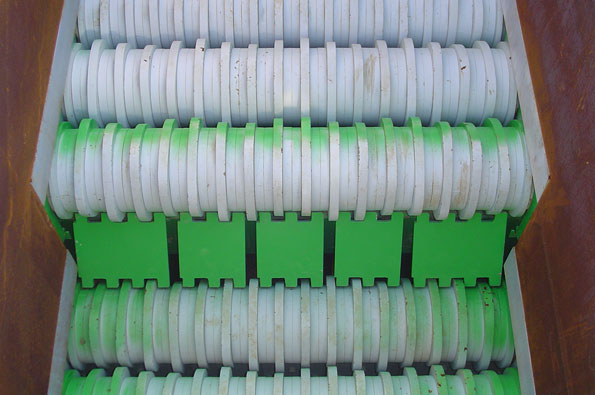

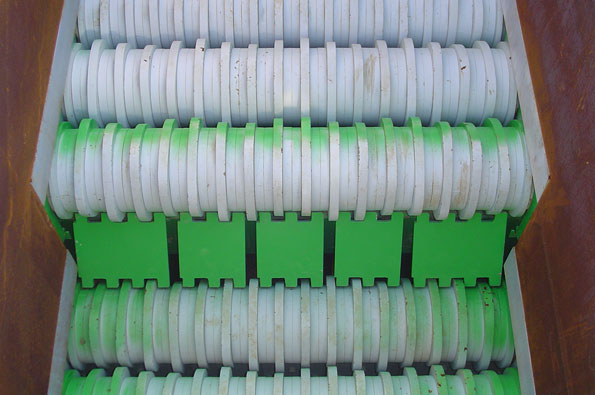

Fig. 2:

Stepped HAZEMAG Wobbler Feeder with cleaning scraper

Attachments

■

HAZEMAG Crushing Plant

HAZEMAG Crushing Plant with Wobbler Feeder

for Cementeria di Costantinopoli

For the Cementeria di Costantinopoli cement works in Italy, HAZEMAG & EPR GmbH has just built a new primary crushing plant. The plant design incorporated the very latest technology with one pre-screening stage, and was developed in close cooperation with the plant’s owner, Signore Dario Rabasco.

The quarried material is transported to a hopper, from where it is extracted by a 10-metre long heavy-duty apron conveyor, the chains and rollers of which are permanently lubricated and thus maintenance-free. The spillage material underneath the apron conveyor is collected by a lightweight scraper chain conveyor.

Fig. 1:

Primary crushing plant with HAZEMAG apron feeder,

stepped wobbler feeder andimpact crusher

Attachments

hazemag_1_2 (JPG)

■