Re: Pulley Load Calculation

Hi Prakash,

Pulley loads can be found via CEMA.

The resultant load is depending on T1, T2 and the weight of the pulley (and you have to consider overhang loads of drive unit, holdback, etc.).

With the relevant wrap angle you can simple calculate the resultant force (i.e. with 180° wrap angle in horizontal position you can simple use the Theorem of Pytagoras).

Hope this helps. ■

Re: Pulley Load Calculation

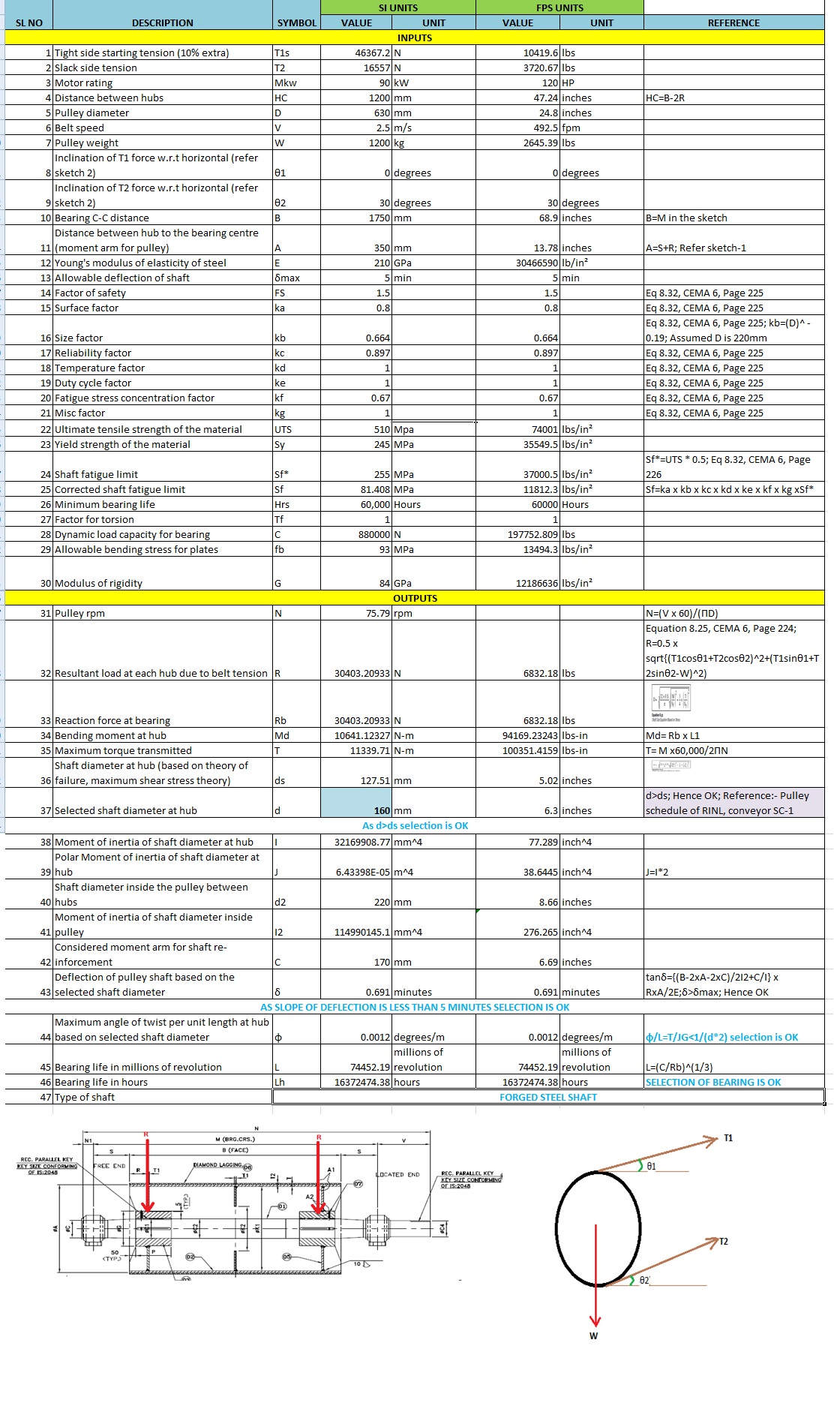

Pulley shaft calculation as per CEMA 06 is attached.Tresca's criterion (maximum shear stress theory) is used as basis for shaft design. ■

Fit For Purpose

Although the CEMA page is handy it does not find the tensions for you. Lines 1 & 2!

If you are still in the business you needed to calculate the tensions at your particular locations. When you do not know the prevailing tensions then it is a waste of time trying to design a shaft: or what? You shouldn't need a textbook, or CEMA, for that.

Regarding optimisation of shaft diameters and bearings: these are hopefully the same otherwise the shaft won't fit ,will it? So you only have to consider the adequacy of the largest drive shaft because the spares holding can then be reduced dramatically. Furthermore, if the sizes and locations of the drives are intentionally correct then there should be very little difference anyway.

With deference to some others: its not rocket science. ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Digging Away Again

Hello John,

it can be made one!

And then, it's a question of relativity ...

For a trial and error approach, such a pulley is beyond rocket science.

However, the datasheet only delivers the most basic design parameters, there's still detail engineering to be done.. and then comes manufacturing, installation, survival on site and so on.

As what concerns the example datasheet given: Don't you think it is design overly conservative (bearing life, deflection..)?

Regards

R. ■

Re: Pulley Load Calculation

Hello,

Somewhat old thread has already got revived. So let me also add some information. The query is about calculation of each pulley load on structure (it is also same as the forces acting on each pulley) and not about the calculation of belt tensions at each pulley. This implies that belt tensions calculation at each pulley is not the query.

Belt is entering on particular pulley at one point, and then the belt is leaving this particular pulley at some other point. Say belt tension is Ta at entry point and belt tension is Tb at belt exit point. The pulley load on structure is vector sum of tensions Ta, Tb and pulley self-weight (W). The tensions Ta and Tb direction is away from each pulley, along the belt. The direction of W is vertical. The vector sum resultant force acts radially at pulley centre. The calculation of such load is routine work.

The designer should consider highest value of Ta and Tb, occurring during starting or steady running or stopping. Consider that situation which gives maximum load. Do not mix-up tensions during steady running, starting and stopping, because these are occurring at different times. The vector sum can be done graphically or mathematically. The graphical method will be easier because the aforesaid forces can be easily plotted on pulleys installation arrangement drawing.

If these pulleys are on single base, then it will be found that total net force acting on base due to belt will be vector sum of belt tension at entry to group of pulleys, and belt tension at exit of group of pulleys. The vertical downward force will be weight of all pulleys. The internal stresses in the base structure would be in accordance with the resultant force on each pulley.

Ishwar G. Mulani

Author of Book: ‘Engineering Science And Application Design For Belt Conveyors’. Conveyor design basis ISO (thereby book is helpful to design conveyors as per national standards of most of the countries across world). New print Nov., 2012.

Author of Book: ‘Belt Feeder Design And Hopper Bin Silo’

Advisor / Consultant for Bulk Material Handling System & Issues.

Pune, India. Tel.: 0091 (0)20 25871916

Email: conveyor.ishwar.mulani@gmail.com

Website: www.conveyor.ishwarmulani.com ■

Allo Allo!

Listen very carefully, read the original thread and then tell the forum how you derive the pulley/shaft load if you do not know the tensions in the belt? ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Pulley Load Calculation

Dear all,

My objective is to find shaft load in which belt pulley is mounted and load being transmitted via belt.

In the case of two pulley belt drives ,the load to the pulley mounting shafts calculation can found by getting guidance in almost all text books(T1 &T2 relations). Where in my case 3 as well as 4 pulleys and one single belt transmit the power. Now i need to find each pulley shaft load what is the procedure to be followed?Any belt hand books dealing this?

Ref.books,ref.materials,sites are welcome

(From this i have to optimize the shaft diameter & bearings.)

Thanks

prakash ■