Re: Chain Conveyor Application

Submerged Chain Conveyors (SCC's) are commonly used for the continuous extraction of bottom ash from power station boilers. ■

Re: Chain Conveyor Application

Sir,

Thank u so much for the reply.

But the same can be carried out by jet pump also.

Why specifically Drag Chain Conveyor?? ■

Re: Chain Conveyor Application

I'm not knowledgeable on the intricacies of jet pumps, but imagine they do operate on a continuous extraction basis whereas SCC's do. ■

Ash Discharge

Hello Senior,

The question for ah discharge of either jet pump or submerged conveyor is where or for what purpose do you have for the ash ?

If its only to go to a ash lagoon, then pumping through a jet pump and pipes is ok.

If you want to use the ash for building blocks or cement addition then a scraper and truck or conveyor is the way to go.

We make many such situations for both.

We can specify / manufacture the pump and pipework , or the conveyor system. ■

Re: Chain Conveyor Application

Large boilers often produce lumps of bottom ash which resemble a small car in size & are very hot. SSCC's are then used because lumps that size & temperature cannot be pumped so easily.

Fly ash is used as a cement constituent. ■

Re: Chain Conveyor Application

The selection depends on a number of things.

SCC's and the like (there are a number of propriety designs on the market) lend themselves to stacking of the ash, which may save realestate for ash disposal. The use of SCC's (or the like) in lieu of water tubs / sluice jets also saves water.

There are pros and cons for capex / opex / maintenance for both sides, though practically here in AUS to the best of my knowledge all new powerstations are going the "SCC" route.

We have a number of units which were originally fitted with the sluice jet arrangement, though have been retrofitted with "SCC's".

Regards,

Lyle ■

Re: Chain Conveyor Application

SSCC's are Submerged Scraper Chain Conveyors & are the present norm for bottom ash removal. They generally have a lift of about 8m which is sufficient to load the bin where some drainage takes place before the ash is broken down for onward conveyance. SSCC's are built to move sideways from under the boiler during maintenance periods.

For comprehensive descriptions of ash disposal issues you should read an appropriate textbook covering large scale boiler operations & then consider your particular situation further. ■

Re: Chain Conveyor Application

Once saw a big one at ESCOM's Lethabo power station

EDIT

I was just thinking, how should you go about establishing the chain pull in a SCC?

In a normal "dry" conveyor it will be the weight of chain and material times a friction factor.

But if the chain and material is submerged surely it's a bit lighter due to the SG of the water therefore the chain pull should be a bit lower.

Comments anyone? ■

Chain Conveyor

Hello Amit,

To all sayed I only can add:

just send me a e-mail so I can reply with the questionnaire to get the needed data to make a technical and comercial offer

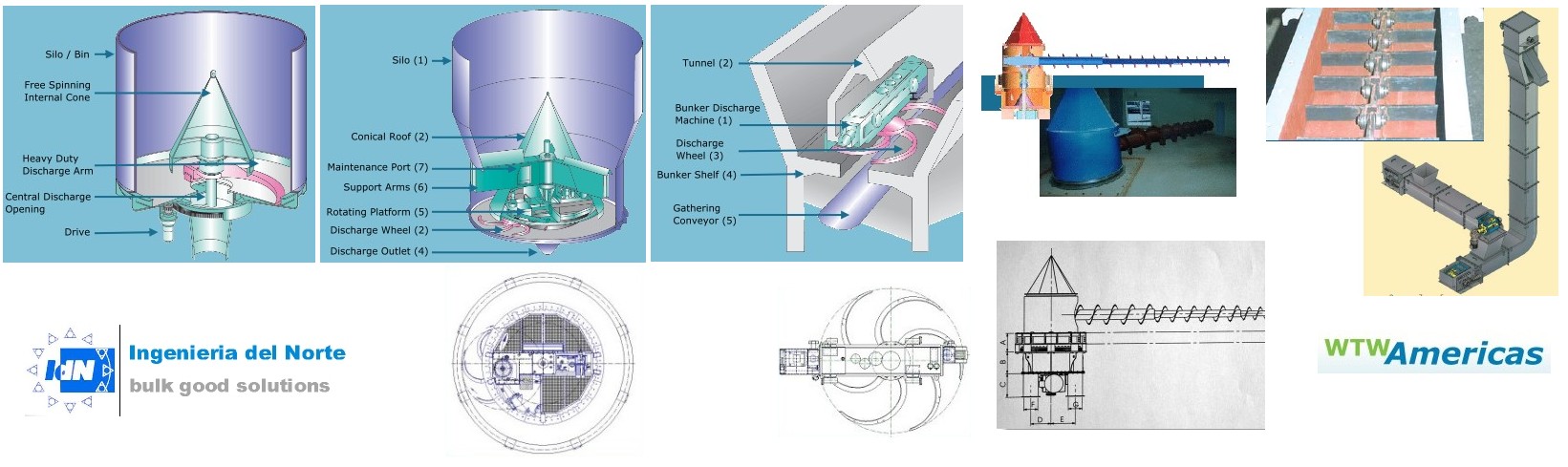

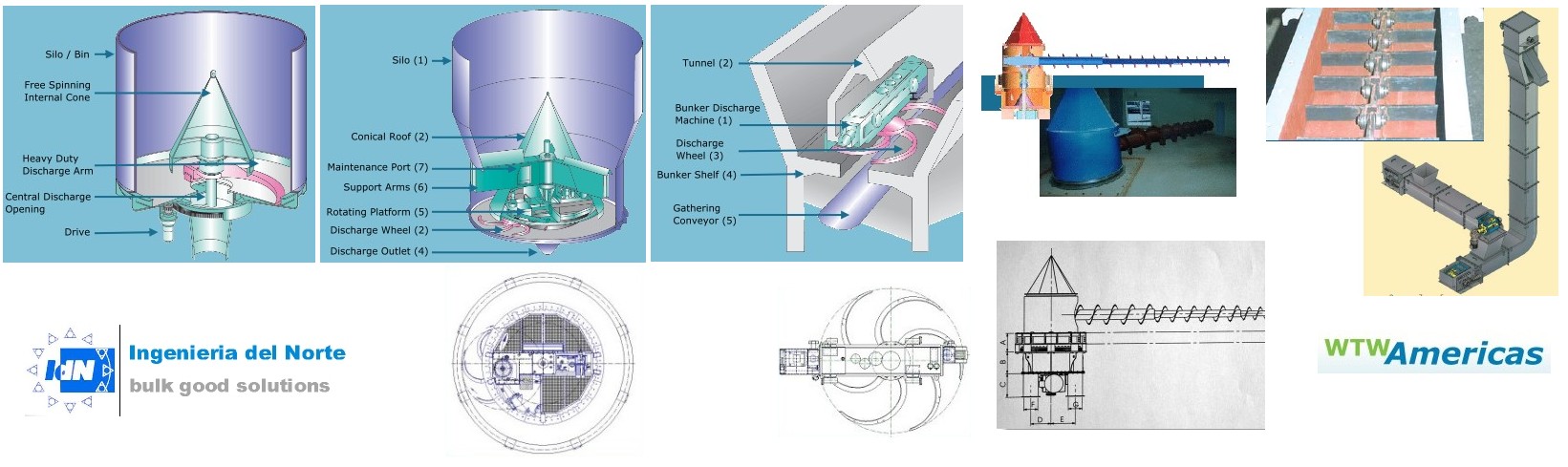

For you first and quick information just two pictures and a link

href="http://www.idn-filtracion.com.ar/idn-wtw.feeder.html" target="blank">www.idn-filtracion.com.ar/idn-wtw.feeder.html

I will contact you in case you are not in my area (Latin America)

Regards

dirk tannebaum

href="mailto:bulk.good.solutions.ar@gmail.com">bulk.good.solutions.ar@gmail.com

buenos aires - argentina

.

Attachments

idn-wtw_tkf-cadena-cajones_aplicaciones (JPG)

■

Load Case Load

EDIT

I was just thinking, how should you go about establishing the chain pull in a SCC?

In a normal "dry" conveyor it will be the weight of chain and material times a friction factor.

But if the chain and material is submerged surely it's a bit lighter due to the SG of the water therefore the chain pull should be a bit lower.

Comments anyone?

True: as long as there is water in the trough. Imagine the submerged scraper chain conveyor, SSCC, has been sidestepped from under the boiler & stands while the maintenance crew do their things aloft. Water will leak out & if the thing hasn't been cleaned then the gadget might have to start up dry to clean it out for maintenance on said gadget, the SSCC. So the chain pull must be adequate for dry working.

I must use that in future design reviews.  ■

■

Re: Chain Conveyor Application

I must use that in future design reviews.

But if I'd pulled it out sideways with a load of ash still in it, I'd be looking to get the back hoe of a JCB in there to drop the ash into a skip.  ■

■

Chain Conveyor Application

Sir,

We can dispos the ash from bottom ash hopper through Hydraulically operated gates to Clinker Grinder and from there ash will be fed to ash slurry sump through jet pump.

I wanted to know that in which case we can go for submurged drag Chain conveyor application in case of bottom ash disposal from hopper.

Regards,

Amit ■