1 Introduction

With a history of approx. 30 years, the pipe conveyor is a proven and well established means for transportation of bulk solids. Compared to conventionally troughed belt conveyors, the rolled-up and closed shape of the pipe belt creates a variety of specific advantages and disadvantages. A decisive advantage results from the topology-flexibility of pipe conveyors. In comparison to conventional conveyor belts, three-dimensional curves with significantly smaller curve radii and higher slopes can be realised. Because of the shape of the pipe belt enclosing the bulk material, immission and emission are impeded.

For a reliable operation of the pipe belt, the bending stiffness in transverse direction, depending on the belt construction, has a great importance. Form forces, resulting from the bending stiffness, keep the belt in its closed form. If these form forces are too small, the edges of the belt could collapse. A safe transport of bulk solids could not be ensured. If these form forces are too high, the pipe belt aspires to open itself between the idler panels.

In this case, the friction among the edges of the belt in the overlap leads to a higher running resistance and a reduced energy-efficient mode of the pipe conveyor. Moreover, a minimum bending stiffness of the belt is necessary, to ensure the required form stability of the belt and to prevent the belt from collapsing or buckling in curves. From the demands for a minimum running resistance, a good shaping behaviour and a high form stability, divergent requirements result with regard to the amount of the bending stiffness.

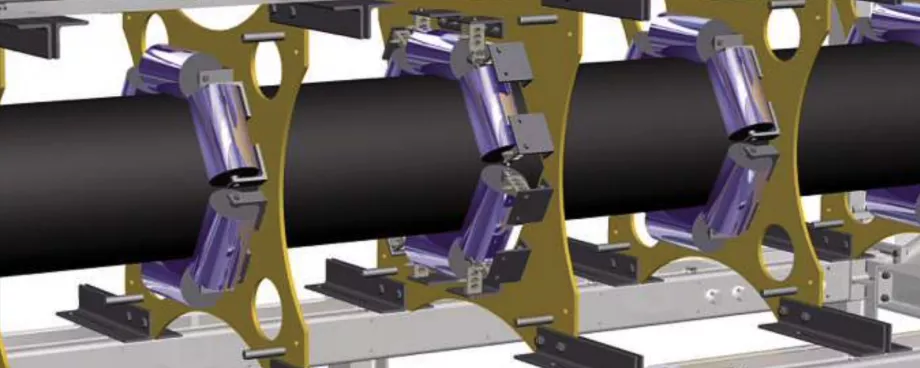

For this reason, in the context of a research project in cooperation between the Phoenix Conveyor Belt Systems and the Institute of Transport and Automation Technology (ITA), the distribution of the belt stiffness resulting from the belt construction and the minimal feasible curve radii was determined. For this purpose, a test rig was designed to examine the form forces of the belt dependent on certain belt and plant parameters (Fig. 1). Therefore, different belt constructions are investigated concerning their form stability at varied belt tensions and adjustable curve radii.

■