That Simple.

This is hardly a bulk handling topic but while I'm here I can tell you that you need a locking device for the screw.

Your options are tab washers, split pins or lock wire. I lost my lock wire pliers many years ago but they are still available in specialised outlets including ebay. ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Spinning In The Fiberglass

New here!

I’m trying to do some root cause analysis for the following case and any help would be lovely!:

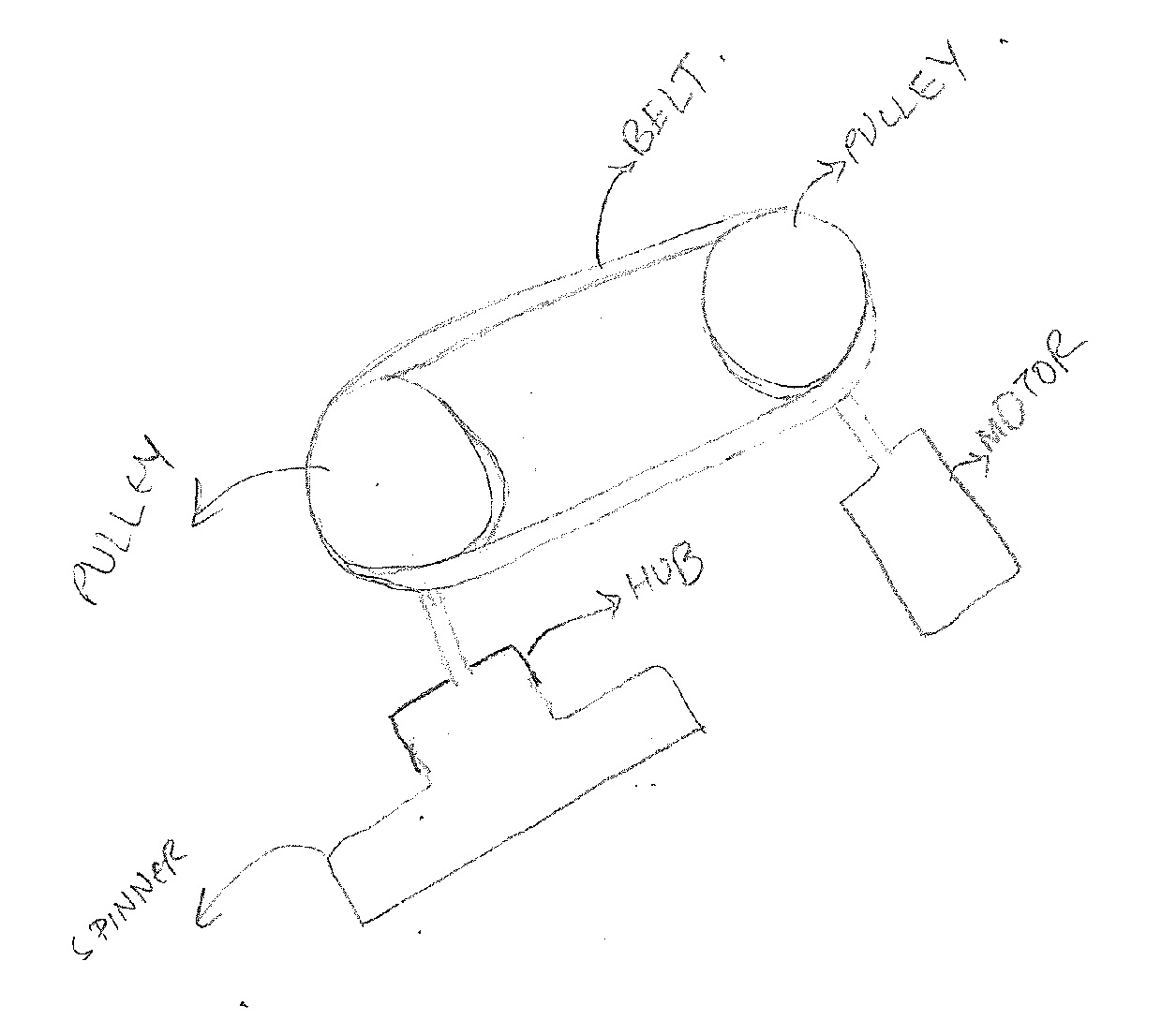

We have a spinner which we use for fiberizing molten glass into thin fine glass-wool (insulation) fibers. It’s circular in shape, with a diameter of about 30 cm. The spinner is spun around at 2-3000 rpm by a motor. It is connected to the motor by hub and belt/pulley as shown below. The spinner is screwed into the hub.

The problem is that in the past two months we have had cases where the spinner actually spun off the hub and fell into the hood underneath! This happened when the motor was stopped but once this also happened whilst starting the motor up. This is at all possible since the spinner is screwed into the hub in anti-clockwise direction and the motor actually runs in clockwise direction. Now, obviously there is relative motion between the spinner and the hub that’s causing the spinner to unscrew itself……as though the hub is jerking and the inertia of the spinner keeps it spinning clockwise and thus the spinner works itself loose. Leaving aside any thermal expansion effects that may be causing this problem (and of course the fact that perhaps the mechanics didn’t tightly screw the spinner into the hub), what other reasons could there be that are causing this relative motion? Could there be some electrical problem..? We don’t have any braking mechanism that suddenly stops the hub when we want to stop the spinner, but can electrical motors, once in a blue moon, do something random to generate a sort of brake on the hub when stopping or even starting up?.....(sorry i don't know much about electrical motors!)

KIND REGARDS

===========================================================================================

As you are using a belt speed reduction drive:

Are you using a thread locker like Blue Loctite???? IF NOT not good one bit!!!!!!!!!!!!!!!!!

what type of shaft to spinner mating surface is there???, Keyed hub and shaft with a woodruff

key and set screw?? did you use loctite on the set screw?

you need to give us more information!!!!

If the mating surfaces were damaged and then reassembled using the old parts that is not good either. ■

Inertia

Hello,

just adding to above posts:

Could you pin down, if there was some change 2 month before? E.g.:

a) Maintenance --> Thread of hub to spinner oiled / cleaned / application of some corrosion protection

b) Process changes --> Stopping times of motor / system decreased, brake installed / updraded / maintained

c) ...

You say you don't brake the spinner, but do you brake the motor? VSD, perhaps? Since 2 month?

If stopped from 2 or 3 krpm within a short time, the breakaway torque of the spinners inertia may be important. You know it, from your systems operation.

Reading & being no native speaker of English, I'd like to check on your wording: "Motor was stopped" means

And then finally I'd consider only one other possible root cause, electrics & control:

a) a (2-phase) short circuit of the motor, making it stop suddenly. But this should have shown up, latest in your electricians input.

b) if the motor is a reversible one, by control means --> pls. check, whether there's been direction reversions.

If correctly engineered, with the stopping time you can calculate a breakaway torque, add a solid margin and design a spinner twistlock device. I imagine you'd like to keep the possibility to unscrew the spinner, so a stopper plate below it could be your friend there. Thread glue is a solution as voted before, but you need to overcome the resistance when unscrewing. How often do you need to do this?

Last question: Your sketch show the conveyor going downwards, and pointedly so. Is this truly so, or did the paper move on the scanner bed and the conveyor is horizontal, or even moving upwards?

Regards

R.

Hot Potato.

There is the drag of molten glass to consider and the possibility of differential expansion of the materials involved. What happens to rubber belts in those conditions? As Leon says there is a lot more to it.

Quoting the Loctite instructions 'In rare instances where hand tools do not work because of excessive engagement length, apply localized heat to nut or bolt to approximately 482°F (250°C). Disassemble while hot.' So if you reach those temperatures your loctite etc. might loosen.

A spring pin might be a cheaper and better balanced remedy but you might get the pin walking out if there is significant imbalance elsewhere.

What have you done so far apart from failing to interrogate your fitters? ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Re: Help With Root Cause Analysis Of Spinner Working Itself Loo…

Thank you all for your replies. I will shortly be replying to all the posts!

Kind Regards ■

Help with Root Cause Analysis of spinner working itself loose whilst rotating

Hi everyone,

New here!

I’m trying to do some root cause analysis for the following case and any help would be lovely!:

We have a spinner which we use for fiberizing molten glass into thin fine glass-wool (insulation) fibers. It’s circular in shape, with a diameter of about 30 cm. The spinner is spun around at 2-3000 rpm by a motor. It is connected to the motor by hub and belt/pulley as shown below. The spinner is screwed into the hub.

The problem is that in the past two months we have had cases where the spinner actually spun off the hub and fell into the hood underneath! This happened when the motor was stopped but once this also happened whilst starting the motor up. This is at all possible since the spinner is screwed into the hub in anti-clockwise direction and the motor actually runs in clockwise direction. Now, obviously there is relative motion between the spinner and the hub that’s causing the spinner to unscrew itself……as though the hub is jerking and the inertia of the spinner keeps it spinning clockwise and thus the spinner works itself loose. Leaving aside any thermal expansion effects that may be causing this problem (and of course the fact that perhaps the mechanics didn’t tightly screw the spinner into the hub), what other reasons could there be that are causing this relative motion? Could there be some electrical problem..? We don’t have any braking mechanism that suddenly stops the hub when we want to stop the spinner, but can electrical motors, once in a blue moon, do something random to generate a sort of brake on the hub when stopping or even starting up?.....(sorry i don't know much about electrical motors!)

KIND REGARDS ■