Plying And Folding

Hello,

Similar to sheet metal, there's cases where you need to adapt to the elastic / plastic behaviour of the material (e. g. minimum bending radii). Here, with a rubber belt, for a given transition length one doesn't want to apply the full bending angle all in one go, but rather make the belt come to its final shape (in trough) by a continuous transition. This gives the belt time to form into the required shape, and you need to consider that the belt is constantly shaped throughout its running around, troughing in, troughing out, and so on. If you want to flex a plate without breaking (rather than bending it), very much bigger radii shall apply than those for bending.

Your approach would apply the full bending angle and then let it wander from the belt edge towards the final location of the bend, diminishing very much the belt lifecycle.

Regards

R.

P.S. the headline should read: bending and folding ■

Relax

The sketch shows a wide centre roller followed by one a little bit longer. How does the belt create this cross section in the first place?

This just a drawn out transition. Do rollers of these dimensions actually exist in standard/preferred form?

Have you examined these proposed cross-sections for spillage potential?

It doesn't ring my bell. ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Re: Another Transition Idler Question

When calculating transition distance the 20° idler does not play in the calculation as the distance from the centerline of the pulley to the first 35° idler is used. This is the true transition distance. The 20° idler is there for support only as the transition occurs. You then need to look at the tension loads in the belt as this transition happens. The shorter the transition distance the higher the tension is as it flattens. Your sketch makes no sense to me as the transition highest loads are at the edge of the belt and does not follow the lines you show. The belt simply lays down from 35° to flat.

As John states you need to be concerned about spillage also and locate the point of where the minimal stresses in the belt are created with out losing the ability to maintain the flow and not spill off the sides.

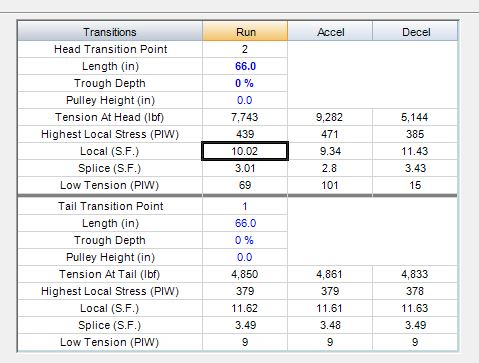

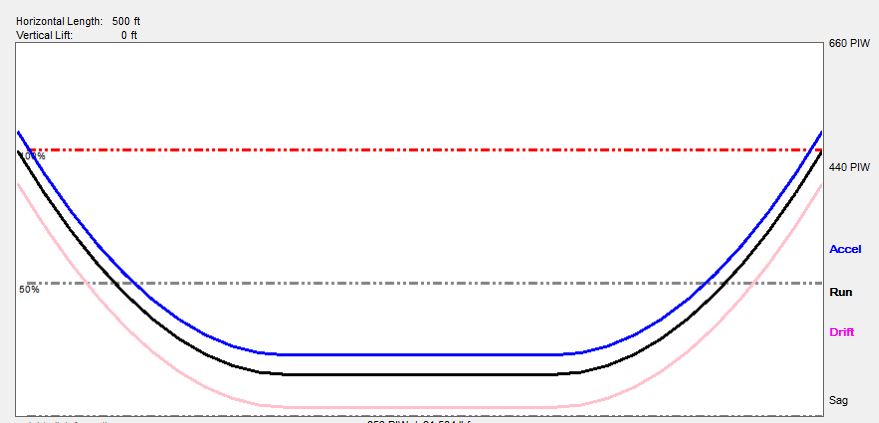

Typical tension diagram for a 48" belt transitioning with the pulley at the same height as the center roll. In order to not exceed the rated belt tension you would require that transition distance to be 66".

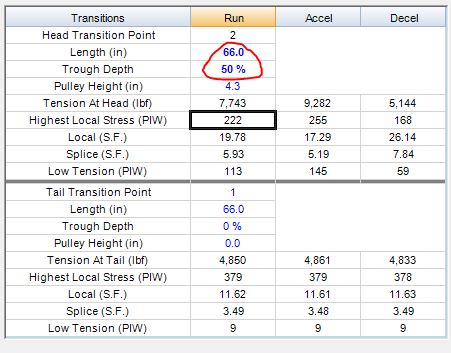

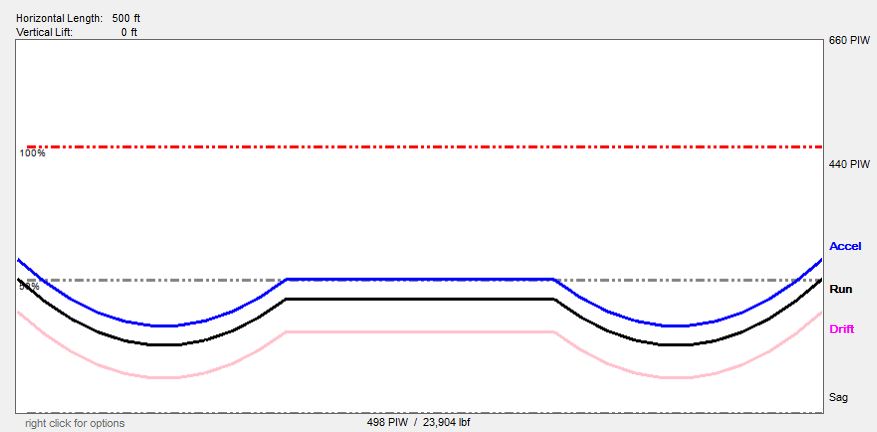

Now take the same conveyor and raise the head pulley 50% (half trough) and see what the effect on tensions will be.

Showing there are other ways to reduce this tension but you need to look at many aspects of the whole transition and shows your line of thinking just does not make any sense. ■

Gary Blenkhorn

President - Bulk Handlng Technology Inc.

Email: garyblenkhorn@gmail.com

Linkedin Profile: http://www.linkedin.com/in/gary-blenkhorn-6286954b

Offering Conveyor Design Services, Conveyor Transfer Design Services and SolidWorks Design Services for equipment layouts.

Response Thanks

Thank you all for the responses. It has given a couple of things to think about. I will drop back by in a couple of weeks.

Apologies for any lack of clarity with the artwork, it should have made appearance of properly spaced transition between pulley and an equal-roll idler with a wider center roll idler intermediate. ■

One In A Hundred

OK. We look forward to your reply. Most questioners don't bother to reply whether the comments have been favourable or not.

I'm glad to see you're not discouraged: you have an idea and want to see it through.

Best of luck. ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Re: Another Transition Idler Question

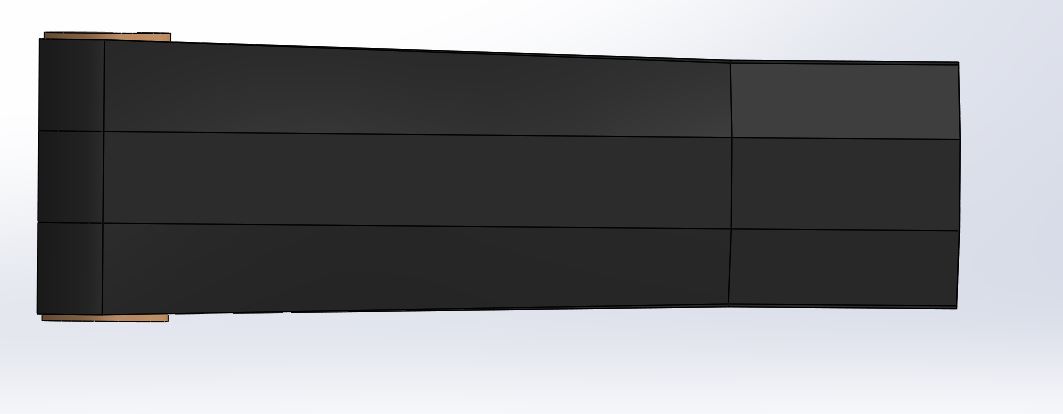

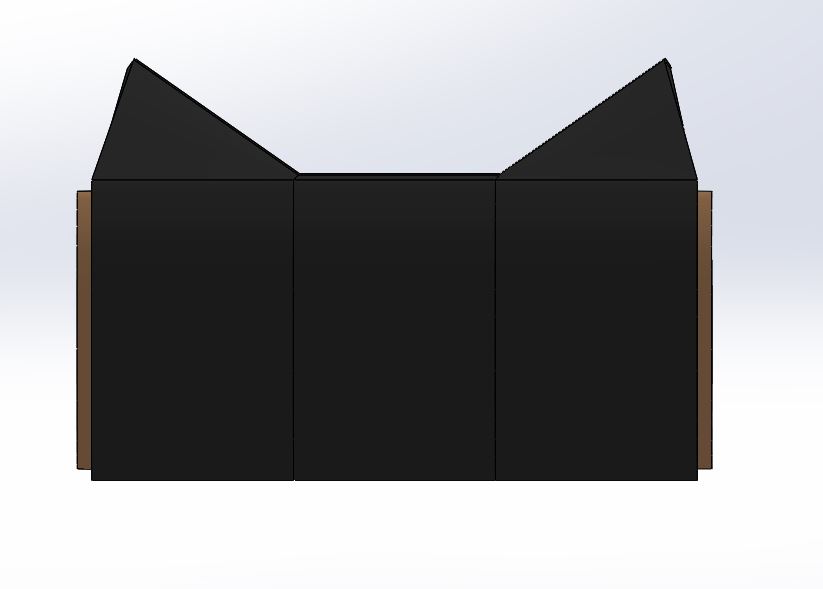

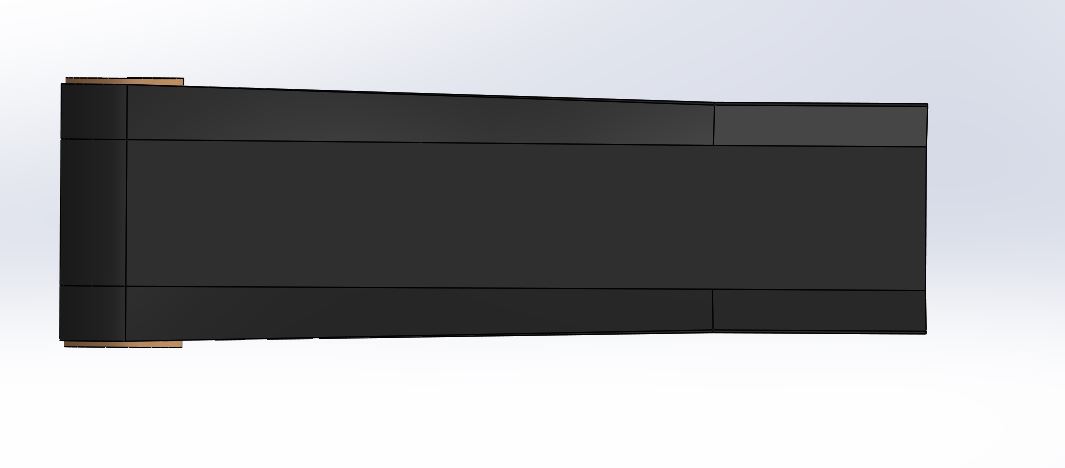

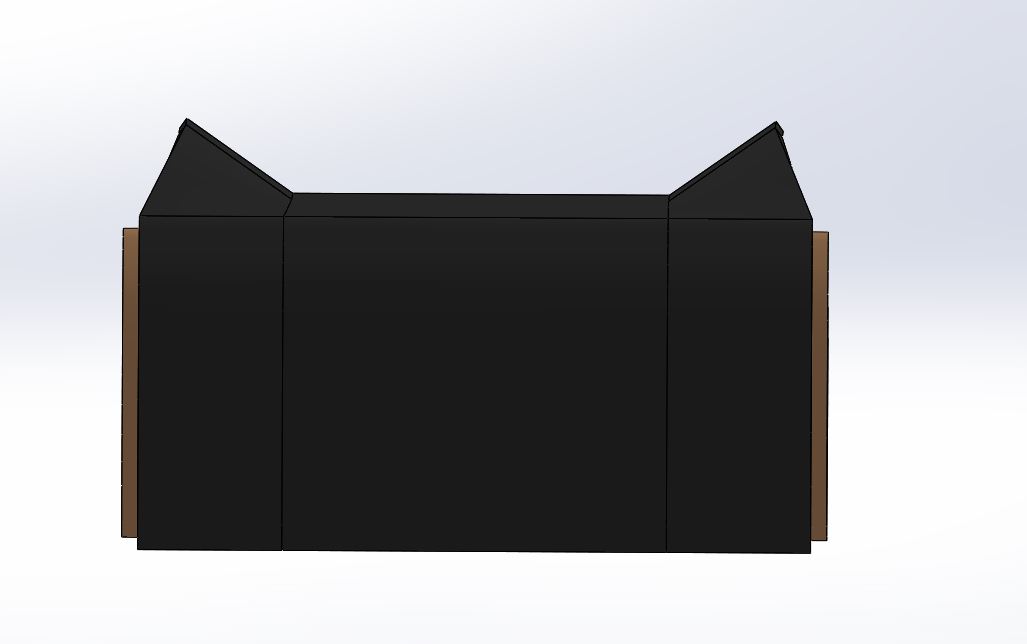

You are looking at the geometry all wrong. The edge of the belt that is folded by the wing rolls will pivot at the joint of where the flat (center roll) meets the wing roll. It simply unfolds from 35° to 0° but the pivot point remains at the same location from the center of the belt and just gradually changes the angle down to zero therefore making it very easy to locate where the 20 degree idler needs to be, at 50% way through the transition the angle will be 35°/2=17.5° so the 20° needs to be slightly before that point for a quick observation but the actual location from the centerline of the pulley can be easily calculated as 20/35 x distance of the 35° to the centerline of the pulley. It does not go off on the angle that you suggest. It doesn't matter if it is equal length rolls or unequal length as in pickle idler rolls the formula is the same and the length of the center roll determines the pivot point of the unfold. I created these sketches in 3D Solidworks and drew the junctions points of the belt as sharp bends to give it a defined edge and show you what really happens.

Equal length rolls.

Unequal length rolls.

Note the line at the center roll does not change or skew off as you suggest.

Hopefully this helps you to understand the geometry of the belt. ■

Gary Blenkhorn

President - Bulk Handlng Technology Inc.

Email: garyblenkhorn@gmail.com

Linkedin Profile: http://www.linkedin.com/in/gary-blenkhorn-6286954b

Offering Conveyor Design Services, Conveyor Transfer Design Services and SolidWorks Design Services for equipment layouts.

Transition Area

You can find full description for transition area in Foundations book from Martin Engineering. ■

Re: Another Transition Idler Question

Here is another good read on transitions.

href="https://forum.bulk-online.com/attachment.php?attachmentid=44047&d=1432908855" title="Name: ConveyorTransitionsPaper.pdfViews: 706Size: 513.5 KB">ConveyorTransitionsPaper.pdf ■

Gary Blenkhorn

President - Bulk Handlng Technology Inc.

Email: garyblenkhorn@gmail.com

Linkedin Profile: http://www.linkedin.com/in/gary-blenkhorn-6286954b

Offering Conveyor Design Services, Conveyor Transfer Design Services and SolidWorks Design Services for equipment layouts.

Yes Indeed!

Thank you very much Gary. A lot of work went into your whitepaper. Can I call it that? ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Re: Another Transition Idler Question

Not my work John. Gulf Conveyor Systems is Colin Benjamin's company. I just pulled it from my collection of articles. ■

Gary Blenkhorn

President - Bulk Handlng Technology Inc.

Email: garyblenkhorn@gmail.com

Linkedin Profile: http://www.linkedin.com/in/gary-blenkhorn-6286954b

Offering Conveyor Design Services, Conveyor Transfer Design Services and SolidWorks Design Services for equipment layouts.

Re-Address Then

Thanks Colin for a most excellent article and also thanks to Gary for bringing it to our attention. ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Re: Another Transition Idler Question

Hello,

The alternative method contemplated by you is welcome but someone has to convince concerned parties (belt manufacturer’s guarantee, acceptability by approving consultant and acceptability by buyer). Innovative method resulting in substantial saving will have immediate appeal to all concerned. Whether rearrangement of transition zone comes in this category ?

Transition zone routine arrangement have following benefits:

1) Transition idlers rollers are interchangeable with other idlers rollers. Only troughing angle is changing gradually.

2) Transition idler frame manufacturing is easy, as idler manufacturers will already have bracket dies for regularly used 3 roll idlers having 15 deg, 20 deg, 30 deg, 35 deg trough, etc.

3) The method for calculating transition zone has widespread concurrence from buyer, consultant, etc. and so its approval is quick, and thereby timely completion of project. The transition zone design concerns such idlers spacing and their levels.

Ishwar G. Mulani

Author of Book: ‘Engineering Science And Application Design For Belt Conveyors’. Conveyor design basis ISO (thereby book is helpful to design conveyors as per national standards of most of the countries across world). New print Nov., 2012.

Author of Book: ‘Belt Feeder Design And Hopper Bin Silo’

Advisor / Consultant for Bulk Material Handling System & Issues.

Pune, India. Tel.: 0091 (0)20 25871916

Email: conveyor.ishwar.mulani@gmail.com

Website: www.conveyor.ishwarmulani.com ■

Another Transition Idler Question

I am interested in discussion regarding why a 20deg idler is used as an intermediate idler in a 35deg transition, as opposed to using another 35deg idler which has a wider center roller (sort of like a 35deg picking idler) in order to keep a straight line from fully-formed belt profile to flat profile at the pulley. Although not completely analogous, if one were to bend sheet metal from flat-state, full-belt-width to fully-developed troughed profile, the bend angle would be constant. Seems like belt transitions should do the same.

href="https://forum.bulk-online.com/attachment.php?attachmentid=43948&d=1431914730" id="attachment43948" rel="Lightbox85976" target="blank"> ■

■