Bedeschi World Review - (Continued)

UNICALCE – BREMBILLA – ITALY (continued)

The crusher with this kind of configuration have turned out to be particularly effective when impact, jaw or gyratory crushers are often in trouble; roller crushers are in fact perfectly suited to process sticky and wet materials with a moisture content up to 25-30%, blocks of hard material mixed to soil, and obviously ordinary hard materials, and generally they are very suitable machines for crushing all those raw materials that due to their moisture content can not be crushed by the traditional crushing systems.

The equipment is scheduled to be delivered by June 2008.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8132-bedeschi.htm" target="blank">https://edir.bulk-online.com/profile/8132-bedeschi.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=Bedeschi+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

Bedeschi World Review - (Continued)

LUCCHINI PLANT - ITALY

Bedeschi has been awarded by Paul Wurth Italia S.P.A. for the supply of two box apron feeders type CNL 6/1500 AB to dose dehydrated blast furnace sludge, blast furnace powders and fine pellets. The useful width of metallic apron at discharge is of 1500 mm. It is complete with a paddle wheel with rotating blades, cleaner for the fines recovery and a hopper with grid.

The plant will be delivered in Autumn 2008.

CONSTANTINOPOLI - ITALY

The project, assigned to Bedeschi, covered the engineering design, supply of the complete crushing prehomogenization and handling section of the new Cementi Costantinopoli Barile plant in South Italy.

The supply included receiving section for limestone (300 t/h), receiving section and crushing for clay (200 t/h), preblending vertical wall and reclaiming (200 t/h), storage for clay and limestone completely installed underground.

The plant has been already successfully commissioned in 2008.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8132-bedeschi.htm" target="blank">https://edir.bulk-online.com/profile/8132-bedeschi.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=Bedeschi+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

Bedeschi World Review - (Continued)

ITALCEMENTI MATERA - ITALY

ITALCEMENTI assigned to Bedeschi a project for a Clay crushing and storage and materials transport to raw mill for the plant located on an inland site near the city of Matera (UNESCO territory), in the South of Italy.

For clay crushing the supply includes a double roller crusher RI 650/1500, a portal reclaimer BEL P 160/21.

For iron ore Bedeschi will also supply an apron feeder RNS 6,5/1500 B.

The machines will be delivered in October 2008.

SIA CEMEX – LATVIA

The project, assigned to Bedeschi, covers the engineering design, supply of a complete clay crushing, staking and reclaiming unit and a limestone staking and reclaiming unit for the new Cement plant in Latvia.

Components for clay unit are a crusher (120 t/h), a stacker (120 t/h) and a Bel S reclaimer (100 t/h); for limestone unit: a stacker (700 t/h) and a BEL S reclaimer (300 t/h). The plant commissioning is scheduled for end 2008.

Raw materials are particularly sticky and high moisture, both clay both limestone, therefore special designed has been considered for all the parts in contact with the product and also bucket excavators to reclaim the materials.

Bedeschi has a contract with SIA CEMEX – Latvia also for the supply of nine apron feeders: a clay apron feeder for primary crushing unit (120 t/h), a limestone receiving unit (max 700 t/h), a raw materials dosing unit, an iron and sand apron feeder (100 t/h).

The supply is scheduled for end 2008.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8132-bedeschi.htm" target="blank">https://edir.bulk-online.com/profile/8132-bedeschi.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=Bedeschi+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

Bedeschi World Review - (Continued)

F.L.SMIDTH A/S FOR KOKSHETAU - KAZAKHSTAN

F.L.SMIDTH A/S assigned to Bedeschi a project for a crushing group to be installed in Kokshetau plant in Khazakstan. Design will consider low temperature climates in the country (up to -39°C)

The job covers the engineering design and the supply of an apron feeder type CNA 10/2000 B characterized by a useful width of metal apron at the discharge (320 t/h) and a double roll crusher type 1000/2000 (320 t/h).

The machines will be delivered in January 2008.

NEW CONTRACT FOR BEDESCHI GROUP IN LITHUANIA:

AKMENES CIMENTAS

Bedeschi is honoured for the awarding of the contract from Akmenes Cimentas. Package 2 and 3 include the complete crushing and raw materials handling as well as process filters.

Based on the raw materials analysis, the plant layout, the budget constraints and the material moisture as well as handling characteristics, the use of a roller crusher for clay (sticky) was selected.

The project is to modernise the existing long time abandoned wet kiln no. 5 with the new dry process.. The project involves equipment supply and services for two main bag filters which will be installed for the de-dusting. To meet Lithuanian and European emission regulations whichever is more stringent.

This project represents an important step and reference because Bedeschi, with its subsidiary, the CTP Team, in cooperation with the pyroprocessing package supplier, will design, deliver and commission a complete new 4500 t/d clinker production line.

Commissioning of the plant is scheduled within 2009.

POLYSIUS A.G. for PODILSKI - UKRAINA

Bedeschi was asked by Polysius AG –Germany a storage system and a and reclaiming system for Podilski project in Ukraina.

The material to be handled is pudlowcy clay and loan with moisture from 13-25%.

The stacking process is performed by a CAR H type stacking system and reclaimed by a BEL C 250/15. On line weighing system to feed directly the mill is included. Machinery is going to be delivered in Summer 2008.

ZAB-INDUSTRIETECHNIK & SERVICE GmbH for SENGILEIEWSKIJ RUSSIA

ZAB-Industrietechnik & Service GmbH assigned to Bedeschi a project for a plant to be installed in Russia at Sengileiewskij.

The machines will be designed and manufactured to work in dusty environment with temperatures varying between –20 °C and +40°C.

Chalk moisture varies from 20 to 23% with a bulk density of 1,2 per t/m3.

Clay and silica have a moisture varying from 15 to 26% with a bulk density of 1,28-1,6 per t/m3..

The scope of supply includes the following machinery:

No. 1 Chalk reclaimer BEL S 400/25 +4, No. 1 Chalk apron feedere type CNS 12/220 with mobile and reversible belt conveyor NGMR 5/1200, No. 1 Clay store (stacker + reclaimer) and No. 1 Pyrite Box apron feedere CNL 6/1500.

The machines will be delivered in April 2009.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8132-bedeschi.htm" target="blank">https://edir.bulk-online.com/profile/8132-bedeschi.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=Bedeschi+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

Bedeschi World Review - (Continued)

CEMEX UK for SOUTHAM QUARRY

In October 2007 Cemex awarded to Bedeschi an installation for Southam works for a Clay Storage System (also known as Stacker Reclaimer) to alleviate the issue of separated raw material being delivered to the kiln at the Rugby Cement Works. The new storage system will be designed to operate 24 hours/day x 7 days/week. It will to handle a nominal 250t/hr. The supply includes receiving section for clay, conveyors up to the storage, stacker and bucket reclaimer type BELF.

CEMENTI ROSSI

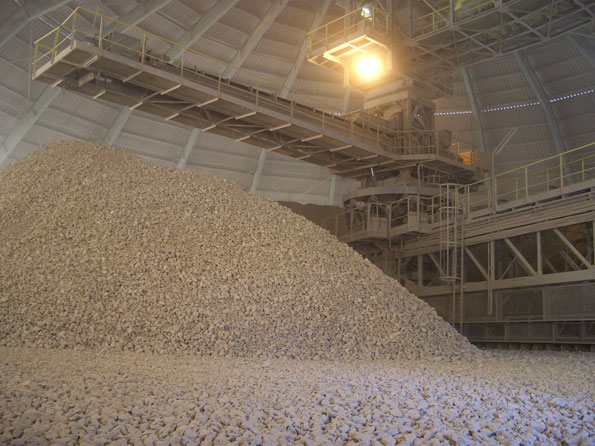

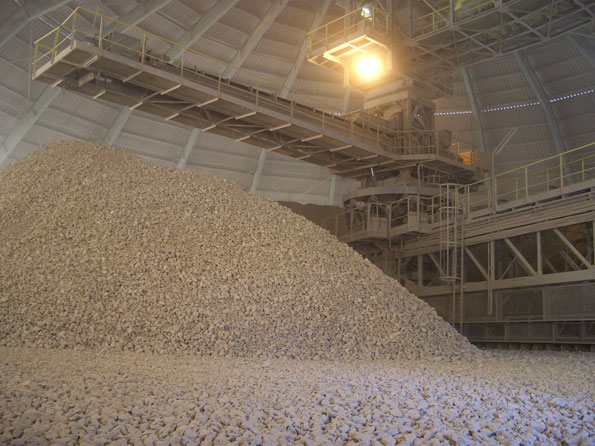

A contract for Bedeschi from Cementi Rossi Italy covers the engineering design, supply and construction of the new circular preblending storage in Fumane plant Italy. The project included a circular dome and a storage with 75 rails diameter. The marl is stacked at a rate of 1100 t/h and reclaimed at 250 t/h with a blending factor 1:10.

Commissioning has been successfully carried out in autumn 2007.

Photo Circular Storage – Cementi Rossi

For more information, please visit:

href="https://edir.bulk-online.com/profile/8132-bedeschi.htm" target="blank">https://edir.bulk-online.com/profile/8132-bedeschi.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=Bedeschi+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

Bedeschi World Review - (Continued)

AFRICA

SOTACIB – TUNISIA

Bedeschi has been asked to supply to Sotacib Usine de la Ferianna a double roll crusher type RI 650/1500 with strong steel structure frame to crush limestone with a humidity varying from 5 to 7%. This machine will replace an existing Bedeschi crusher 30 years old and will double the capacity.

Machinery is scheduled to be delivered in Summer 2008.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8132-bedeschi.htm" target="blank">https://edir.bulk-online.com/profile/8132-bedeschi.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=Bedeschi+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

Bedeschi World Review - (Continued)

ERCE ALGERIA

ERCE has awarded Bedeschi the contract for the engineering design, supply and erection of the new limestone longitudinal storage for limestone.

The project includes a new 450 tph frontal reclaimer type PAL T 160/28+5.

The plant will ensure a storage capacity up to 75.000 t for limestone/clay, over two piles, and an optimum output homogenization effect.

The erection of the plant is in progress now.

LAFARGE ALEXANDRIA EGYPT

Bedeschi has defined with Lafarge the supply for a new Double Roll Crushing unit type RI 650/2000 unit for Lafarge Titan in Egypt.

The material to be crushed is marl and clay and the output capacity is of 350 t/h.

Lafarge also awarded to Bedeschi an Apron feeder CNS 12/2000 for marl with 15% moisture and 1,5 t/m3 bulk density. The useful width of metal apron at the discharge is of 2000 mm.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8132-bedeschi.htm" target="blank">https://edir.bulk-online.com/profile/8132-bedeschi.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=Bedeschi+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

Bedeschi World Review - (Continued)

ZLITEN CEMENT FACTORY – LIBYA

CEMAG Anlagenbau GmbH from Germany has awarded Bedeschi the contract for the engineering design, supply and erection of the new limestone storage plant for the Zliten cement factory in Libya.

The project includes a new 1.680 tph capacity longitudinal luffing stacker (type STK 24/1600), a 600 tph frontal reclaimer type PAL T 200/32+4, an additive reclaimer PAL F 130/20 for limestone and iron ore with a nominal capacity of 160 t/h and the total automation of the storage.

The plant will be complete with many dedusting filters, piping and air compressor for filter cleaning supplied by the CTP Team Co. a company of Bedeschi group specialized in environmental protection for cement industry.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8132-bedeschi.htm" target="blank">https://edir.bulk-online.com/profile/8132-bedeschi.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=Bedeschi+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

Bedeschi World Review - (Continued)

CIMENT DU SAHEL – SENEGAL

Le Ciment du Sahel S.A. awarded to Bedeschi the supply of machinery for the extension of the existing cement line, whose clinker has a capacity of 3.600 t/day. Bedeschi supply concerns all the raw material handling system of the mentioned extension.

Additives crushing unit complete with one apron feeder type CNA 10/2000 (450 t/h), two crushers one primary type RL 650/2000 and one secondary type RL 450/2500 both with cylindrical teeth, one preblending circular storage system type STKR 22/1200 (max 900t/h) and a reclaimer type PAL T 160/35 (max 500 t/h) and additive storage with new bucket reclaimer type BEL F 300/16 (300 t/h) and all the conveying equipment of approximately 1500 meters to the hoppers of the cement mills as well as all dedusting filters by CTP Team . The supply consists of an important integration with the existing parts because they are interested by new by-pass and connections to the existing transferring towers.

The plant commissioning is scheduled for early 2009.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8132-bedeschi.htm" target="blank">https://edir.bulk-online.com/profile/8132-bedeschi.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=Bedeschi+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

Bedeschi World Review - (Continued)

MASS JORDAN – SUDAN

Mass Jordan for Inv. & Trad. Co. awarded to Bedeschi two contracts: one for the supply of a clay longitudinal storage and one for a clay crushing group.

The first unit includes a stacker type 12,5/800 (300 t/h) and a reclaimer type BEL F 250/19 (250 t/h), in the second unit there are an apron feeder type CNA 9/2000 B and a primary toothed roller crusher type RI 650x2000 (500 t/h).

The supply is scheduled for late 2008.

LAFARGE for CIMENTERIE TETOUAN - MAROC

Bedeschi in December 2007 was awarded with a contract from LAFARGE-Cimenterie Tetouan El Mashar, the extension of the clinker capacity for the Tetouan cement factory whose capacity is of 1.000.000 t/y.

Material to be treated are Limestone with 7% moisture, density 1,5 t/m3 and additives (limestone HT, pelite, phtanite and iron ore) with an average moisture of 7,25% and density from 1,4 to 2,2 t/m3.

The contract represents the doubling of the previous production line No. 2 successfully commissioned by Bedeschi in 2002.

The actual supply includes the complete raw materials line downstream the crushing unit and before the clinker silos.

The supply is composed of the feeding conveyor belts from the crusher, the circular prehomogenization limestone storage section, the receiving and unloading trucks station, the belt conveyors line and the longitudinal storage section for additives.

The machinery for the circular storage section are : stacker STKR 15/1000 nominal capacity 600, reclaimer Pal T 100/23 and conveyor belts.

The machinery for the longitudinal storage section are Box feeder CAN 9/1200B, reclaimer Bel F 160/18 nominal capacity 142 m3/h, conveyor belts, air filters, metal detectors.

The above mentioned machines correspond exactly to the previous supply to confirm Bedeschi’s reliability and good outcome of the last years.

In the present project, the Bedeschi’s subsidiary, the CTP Team have supplied the filters to be positioned in the most strategic points of the plant so to reduce the dust which is one of the characteristics of the material extracted in this part of the country.

Machines are scheduled to be delivered next Autumn 2008.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8132-bedeschi.htm" target="blank">https://edir.bulk-online.com/profile/8132-bedeschi.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=Bedeschi+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

Bedeschi World Review - (Continued)

ITALCEMENTI S.P.A. ITALY for AIT BAHA - MAROC

In February 2008, Bedeschi was asked by Italcementi – Italy to install at Ait Baha Cement plant in Maroc its applications to the cement industry, specifically to the preblending storage of limestone, clay and silt, coal or petcoke, raw mill additives.

Limestone will have a total storage volume of 50.000 t: the process will be performed by a stacker STK 25/1600 for a nominal capacity of 2000 t/h, a reclaimer PAL T 160/34+4, nominal capacity 800 t/h.

Clay and silt storage will have a total storage volume of 15.800 t: the process will be performed by an apron feeder type "RNS 7,5/2000, a stacker STK STK 21/1000 for a nominal capacity of 500 t/h, two reclaimers PAL T 130/25+4, nominal capacity 300 t/h.

Cement additives to be handled will be: pozzolana, gypsum and limestone.

The equipment will be complete with conveyor belts, Stacker STK 20/1000

for a nominal capacity of 500 t/h, reclaimer PAL F 130/25 nominal capacity 200 t/h, bag filters and belt conveyors:

Coal or petcoke storage for a total stored volume of 50.000 t, will be complete with stacker STK 25/1200, reclaimer PAL T 130/34+4 nominal capacity 150 t/h, rails and belt conveyors.

Raw mill additives as iron ore and bauxite line composed by a Box feeder type CNT 14/2500 with a useful width of 2500mm., screen type VD 2000, chain bucket elevator, belt conveyor and bag filters. Complete conveyor’s lines will be also supplied to give a turn-key package.

In the present project, the Bedeschi’s subsidiary, the CTP Team will supply the filters to be positioned in the most strategic points of the plant so to reduce the dust which within the limit of environmental regulations.

Part of the equipment will be delivered by the end of 2008 and the remaining part by March 2009.

MIDDLE EAST

CIMPOR YIBITAS for HASANOGLAN PLANT - Turkey

Bedeschi was awarded with a contract from Ekon for Cimpor Yibitas in Hasanoglan plant for a Clay crushing and handling system complete with an Apron feeder CNA 6,5/1500 B, a primary toothed roller crusher RI 650 x 1500, a storage system with belt conveyor stacking bridge type “STKP 18/1000” and reclaiming with excavator type “BEL C 100/14.

A second equipment for the Limestone handling (raw material and cement additives) is complete with 2 apron feeders CAN 6,5/1500 B and a portal reclaimer PAL SP 130/18.

For coal and petkoke handling, the line is composed by an apron feeder CNA 6,5/1500 B and a portal reclaimer PAL SP 100/18.

The equipment is scheduled to be delivered by the end of September 2008.

AS CIMENTO – TURKEY

AS CIMENTO commissioned Bedeschi the supply of a circular storage for limestone and clay mixture. The total storage volume is 81700 t with staking max capacity equal to 2000 t/h and reclaiming max capacity equal to 900 t/h.

The stacker type is STK 29/1600 and the reclaimer type is 220/49. The intervention concerning the installation of the pre-homogenization storage will substitute the function of the raw material storage of the longitudinal existing storage already supplied by Bedeschi some years ago. It will be the additives storage with the addition of a new side lateral reclaimer for the combined handling and reclaiming of high grade amrl, low grade marl and mixture of iron ore and Bauxite.

AS CIMENTO commissioned to Bedeschi the supply of the reclaimer PAL P 160/26 (400 t/h): the machine will be delivered in the next months.

TOKAT CEMENT PLANT

ADOÇIM ÇIMENTO BETON SAN. Ve TICARET A.S. has awarded Bedeschi the contract for the engineering design, supply and erection of the new limestone longitudinal storage for limestone.

The project includes a new 1000 tph capacity longitudinal stacker (type STK 24/1200) and a 550 tph frontal reclaimer type PAL T 200/30,5+4.

The plant will ensure a storage capacity up to 50.000 t for limestone, over two piles of 265 m length, and an optimum output homogenization effect.

The plant has been successfully commissioned last March 2008.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8132-bedeschi.htm" target="blank">https://edir.bulk-online.com/profile/8132-bedeschi.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=Bedeschi+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

Bedeschi World Review - (Continued)

DENIZLI - Turkey

Bedeschi is to supply to Denizli Cimento in Turkey a semi-portal reclaimer for limestone. The raw material crushing capacity of the plant is 950 t/hr with 2 crushers and the grinding capacity is 400 t/hr with 2 mills.

Bedeschi’s supply includes a portal scraper reclaimer PAL SP 160/22 for a nominal capacity of 500 t/h with a reclaimer boom with a centre to centre distance of 22,5m.

The delivery of the machine is scheduled for the end of September 2008.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8132-bedeschi.htm" target="blank">https://edir.bulk-online.com/profile/8132-bedeschi.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=Bedeschi+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

Bedeschi World Review - (Continued)

CIMENT DE SIBLINE

Bedeschi has defined with Ciment de Sibline – Lebanon, the supply for the bug revamping of the existing crushing system supplied by Bedeschi several years ago for their plant in Beirut.

The supply includes two new complete rotors with new shapes and teeths for the update of the capacity to the new material and production features.

AMERICA

RIVER CEMENT

In July 2006 RIVER CEMENT (a subsidiary of BUZZI UNICEM U.S.A) awarded to Bedeschi America a contract for the supply for the expansion project of RIVER 7000 mTPD Plant, including:

No. 1 Crushing Unit for clay and additives complete with one hopper to receive the material unloaded from trucks, one metal apron feeder type CNA 10/2000, one disk type screen VD 2000 and one double roller crusher type RL 850/2000.

No. 1 Clay Storage and Reclaiming System, which comprises: one pusher type reclaimer BEL F-R 130/14, one metal apron feeder type CNSD 8/2200 AW, located under the pile at the discharging end of the reclaimer.

No. 1 Limestone Storage and Reclaiming System, which comprises one slewing and luffing stacker type STKR 23/1400 and one slewing frontal stacker with rake type PAL T 200/37

Erection is now in progress.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8132-bedeschi.htm" target="blank">https://edir.bulk-online.com/profile/8132-bedeschi.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=Bedeschi+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

Bedeschi World Review - (Continued)

ASH GROOVE MOAPA PLANT

Bedeschi America was awarded by Fuller Inc. for Ash Groove Moapa plant for a new clay crushing unit. The plant includes: a box feeder type CNA and a crusher type RL with a production capacity up to 900 tph of sticky clay (moisture up to 27%).

Bedeschi’s double roller crushers are innovative though very simple machines. Basically they consist of two toothed rollers turning in opposite directions.

The speed of the rollers can be differential, making the material to be crushed passing through the gap of the two crusher’s rotors.

When the differential speed is adopted, the material is crushed not only by compression strength but also by the combination of shear and tensile stresses.

Thanks to this processing system, any type of raw material can be crushed, from hard (as limestone and rock) to soft (as clay, soil and mud) or even plastic (as wood or rubber tyre).

The rotation speed of the crusher rotors is very low, especially if compared to the traditional impact crushers, so low, in fact, that the peripheral speed is 1,5 ÷ 3 m/sec.

KEYSTONE CEMENT COMPANY

A contract has been agreed between Keystone Cement Co. from South Carolina and Bedeschi through Bedeschi America for the supply of a Crushing Group formed by an apron feeder CNA 10/2500 B, a crusher type RL 650/2500 and a crusher type RL 450/2500 for limestone.

Input size of material for the Primary Crusher does not exceed 48 inches/1200 mm. Moisture content of the limestone does not exceed 5% and this is understood to be mainly surface moisture. Throughput of both crushers not to exceed 40,000 tons per week.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8132-bedeschi.htm" target="blank">https://edir.bulk-online.com/profile/8132-bedeschi.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=Bedeschi+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

Bedeschi World Review - (Continued)

BUZZI - MEXICO

BUZZI UNICEM S.P.A – Italy awarded to Bedeschi the supply of a clay and a limestone circular pre-homogenization plant for APZ in Mexico.

The clay storage production is of 400 t/h and reclaiming capacity is of 150 t/h.

The limestone storage production is of 1500 t/h and reclaiming capacity is of 500 t/h.

The aim of prehomogenization is to realize a pile of material coming from the crushing unit, with very fluctuant characteristics and to reclaim it in order to have a product with characteristics, constant as much as possible.

The process is performed by a rotary stacker STK 23/1400 and by a reclaiming scraper Pal T 200/36 applied to a rotating central column for clay while the storage for limestone is complete with a rotary stacker STK 16/800 and by a reclaiming scraper Pal T 100/26 applied to a rotating central column

Material is scheduled to be delivered by April 2009.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8132-bedeschi.htm" target="blank">https://edir.bulk-online.com/profile/8132-bedeschi.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=Bedeschi+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

Bedeschi World Review - (Continued)

FAR EAST

HA TIEN 2 - VIETNAM

Bedeschi was asked by Vietnam National Cement Trading Company ( Vinacimex ) the “Supply of Design, Equipment, Materials and Technical Services for complete Production Line located at Kien Luong Town, Kien Luong District, Kien Giang Province, S.R Vietnam” for the Project: Ha Tien 2.2 Cement Production Line Project.

The supply includes: Crushing, transportation and storage of materials, including sections of limestone crushing, receiving of limestone, sand, literate, clay exploitation, transporting to the storage and transporting to the dosing station of the mill.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8132-bedeschi.htm" target="blank">https://edir.bulk-online.com/profile/8132-bedeschi.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=Bedeschi+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

Bedeschi World Review - (Continued)

HA TIEN 2 - VIETNAM (continued)

In detail the supply is as follows:

Stationary crane has a max. working radius from centre of slewing crane to centre of grab of 22.000 mm. To unload sand (moisture content max. 10%), Laterite (moisture content max. 10%, size ≤ 60 mm.) and limestone (moisture content max. 2%, size ≤ 60 mm) at a speed for hoisting gear with full load of 60 m / min.

The receiving hopper is placed on quay and it is suitable to be loaded by grab with capacity of approx. 5 m3. It is followed by an Apron conveyor type CNPD 6/1200 B for the process of sand, laterite and khoe la limestone.

The material is then conveyed by belt conveyors and complete with bag filters.

The receiving hopper is placed on quay and it is suitable to receive unloading from trucks, with capacity 32-36 t. It is followed by an apron conveyor, belt conveyor and bag filters.

All bag filters are supplied by our subsidiary the CTP Team. The bag filters have automatic bags cleaning and are provided with TBR bag fixation system and bag insertion/extraction from the top.

The line is complete with a receiving and transporting equipment for clay by means of a clay bucket excavator, apron conveyor type CNSD 6/1500 AB, double roller mixer crusher type RI 650/1500, belt conveyors and bag filters.

Limestone and transportation after storage is performed by a stacker type STK 24/1200, a reclaimer type PAL T 160/31+4.

Silica, laterite and transportation after storages processed by a tripper type TR 13/800 which allows to transfer the material discharging it from the feeding belt conveyor.

The receiving concrete hopper is placed on quay and it is suitable to receive unloading from small dumpers. The metal box for material receiving is an apron conveyor type CNPD 4/1000 B followed by belt conveyors for which special attention has been paid to the standardization to be rational and convenient for installation, repair and replacement of spare accessories.

The delivery of material is scheduled for February 2009.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8132-bedeschi.htm" target="blank">https://edir.bulk-online.com/profile/8132-bedeschi.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=Bedeschi+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

Bedeschi World Review - (Continued)

HATIEN PHU HUU PROJECT

Bedeschi received an order from Loesche GmbH from Germany for the supply of the project of “Terminal for receiving, grinding and distribution of cement in the South” of Ha Tien 1 Cement Company, which will be invested and constructed at Phu Huu ward in Ho Chi Minh City.

The total project investment scope including cement grinding system with capacity ≥ 150 T/h, two cement packaging systems 2 x120T/h in combination with bulk and bagged cement truck loading and ship loading dispatch system with capacity of ≥1.0mil.tons of cement per year. Bedeschi scope of work is the complete supply for technological sections from material receiving and storing (clinker, gypsum, additives), transporting materials to feed bin of cement mills, storages and dedusting.

Reliable filters by CTP Team also will complete the dedusting section of the plant.

BUT SON CEMENT PLANT - VIETNAM

Bedeschi announces a contract with Kawasaki Plant Systems, Ltd. for the supply of No. 3 Apron Feeders for the But Son Cement Plant in Vietnam.

Each Apron Feeder Type CNPD3,5/1000 AC is dedicated to a type of material: one is for clay, one for iron ore and one for clinker.

The material was delivered by the end of Summer 2007.

LAFARGE MALAYASIA

Bedeschi supplied to Lafarge a special apron feeder to dose material including a weighing system. Capacity ranges up to 250tph. A board electronic weighing system will automatically dose the material according to given set point.

CHINFONG HAIPHONG CEMENT CORPORATION

Bedeschi S.P.A. has been awarded a contract by Taiwan Cement Engineering Corporation for the Chinfong Haiphong Cement Corporation for the supply of a Clay Stacker and Reclaimer. The preblending aim is to stack piles with incoming material also with very fluctuating features, and to reclaim it in order to have the output with the most possible constant features. This is made by storage system with stacking bridges Type STKP and reclaimer Type BEL C.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8132-bedeschi.htm" target="blank">https://edir.bulk-online.com/profile/8132-bedeschi.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=Bedeschi+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

Bedeschi World Review - (Continued)

HANDLING FOR BIM SON RAW MATERIALS CEMENT PLANT

Bedeschi in July 2006 was awarded with a contract from ISHIKAWAJIMA-HARIMA HEAVY INDUSTRIES, Tokyo, Japan for a series of machines for the new cement factory of Bim Son Cement Plant in Vietnam.

The scope of the contract is the supply of all machines concerning handling of raw material and particularly:

No. 1 Circular storage for limestone, total stacking volume 47.000 T, diameter of the storage 86 m., storage production nominal 1.400 max 1680T/h and 800 T/h for reclaiming system.

No. 1 longitudinal stacker (type STK 24/1400), nominal capacity 1400 T/h and a 550 tph frontal reclaimer type PAL T 200/40.

No. 1 Coal storage system, total stored volume 12.000 t, stacking capacity 200 T/h and reclaiming capacity 150 T/h complete with mobile and reversible belt conveyor with a capacity of 200 T/h.

No. 1 Lateral scraper Pal F 100/22 with a nominal capacity of 150 T/h

No. 1 clay storage: storage system with belt conveyor stacking bridge type “stkp” and reclaiming with excavator type “Bel C”:

No. 1 Stacking bridge type STKP 25/800, stacking capacity 300, max 330

No. 1 Reclaimer Bel C, reclaiming capacity 150 T/h

The plant has been successfully commissioned last March 2008.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8132-bedeschi.htm" target="blank">https://edir.bulk-online.com/profile/8132-bedeschi.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=Bedeschi+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

Bedeschi World Review - (Continued)

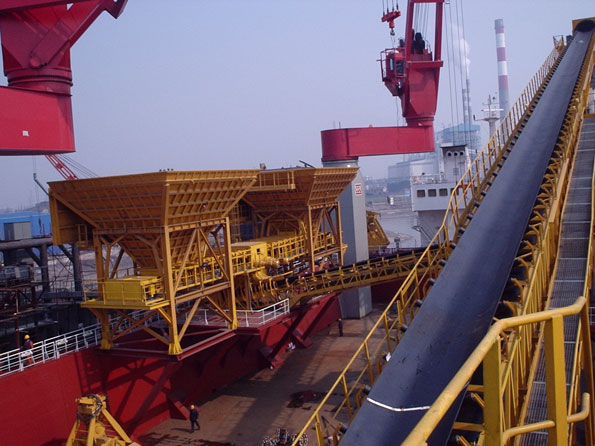

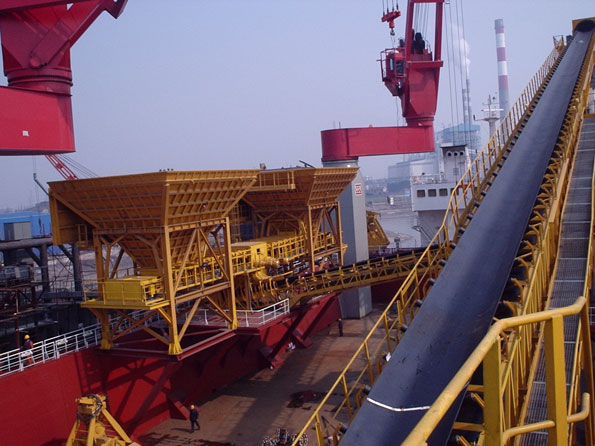

BULK PROSPERITY- INDIA

Bedeschi was asked by Coeclerici Logistics – Italy to install its applications to the coal industry, specifically to the coal conveying system of a plant in India.

Bedeschi has been charged of realizing:

No. 2 Coal receiving hoppers with extractors, volumetric capacity of each hopper equal to approx. 50 m3. Under each receiving hopper there is a rubber extractor suitable to transfer 1200 t/h of coal from the hopper to the loading belt system. Barge loader SHL16/1600 and shiploader SHL33/1600 to load both barges and cape vessels are also operating to realize a complete off shore transfer station.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8132-bedeschi.htm" target="blank">https://edir.bulk-online.com/profile/8132-bedeschi.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=Bedeschi+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

Bedeschi World Review - (Continued)

BULK PROSPERITY- INDIA (continued)

For more information, please visit:

href="https://edir.bulk-online.com/profile/8132-bedeschi.htm" target="blank">https://edir.bulk-online.com/profile/8132-bedeschi.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=Bedeschi+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

Bedeschi World Review - (Continued)

TRUSTWORTH - INDIA

Five ship-loaders SHL 1600 with a nominal capacity of 2000 T/h for iron ore have been delivered. The installation of machines is in progress at the moment while the 6th shiploader has just been ordered in April 2008.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8132-bedeschi.htm" target="blank">https://edir.bulk-online.com/profile/8132-bedeschi.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=Bedeschi+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

href="https://forum.bulk-online.com/search.php?action=showresults&searchid=499955&sortby=lastpost&sortorder=" target="blank">https://forum.bulk-online.com/search...ost&sortorder=

Attachments

■

Bedeschi World Review

Bedeschi Annual World Review

EUROPE

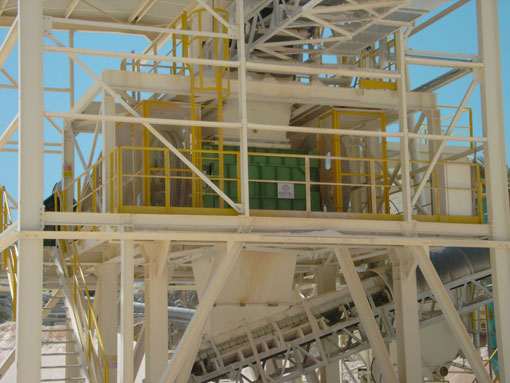

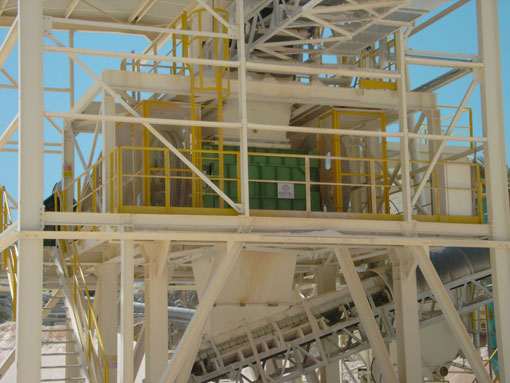

UNICALCE – BREMBILLA – ITALY

In October 2007 Unicalce awarded to Bedeschi an installation for a Crushing unit for hard limestone (up to 2000kg/sqcm). It is the second working group in this quarry and the new supply includes an apron feeder type CNA 6,5/1500 B, a crusher with toothed cylinders RL 650/1500. The teeth shape is particularly suitable to crush big blocks of material. The cleaning of teeth is guaranteed by a set of adjustable scrapers positioned all long each rotor. The crusher with this kind of configuration have turned out to be particularly effective when impact, jaw or gyratory crushers are often in trouble; roller crushers are in fact perfectly suited to process sticky and wet materials with a moisture content up to 25-30%, blocks of hard material mixed to soil, and obviously ordinary hard materials, and generally they are very suitable machines for crushing all those raw materials that due to their moisture content can not be crushed by the traditional crushing systems.

The equipment is scheduled to be delivered by June 2008.

For more information, please visit:

https://edir.bulk-online.com/profile/8132-bedeschi.htm

http://www.google.com/search?client=...UTF-8&oe=UTF-8

https://forum.bulk-online.com/search...ost&sortorder=

Attachments

bedeschi-1 (JPG)

■