Re: Synchronize Two Motors

It is not clear how these drives are arranged or their purpose. Is there a drawing available. ■

Untitled

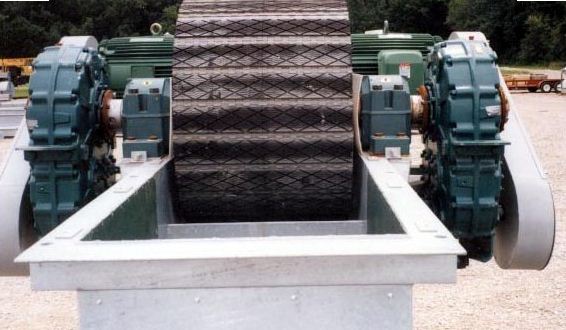

In attached you can see head pulley of the bucket elevator with dual drivers. ■

Re: Synchronize Two Motors

This is seen as a method to transmit a very high, but balanced torque to the pulley shaft. The powder will be shared by the two drives as they will be self-synchronising on the common shaft. It seems well engineered. even if a slightly more expensive way than using a singe, larger motor and gearbox that would require a larger shaft. ■

Untitled

Because it is normal that all same models motors from manufacturer come with little difference in RPM (up to 5%aprox.). In this case one of the motors will work in false manner. So, my question from these facts. ■

Re: Synchronize Two Motors

Difference in RPM is a function of motor slip or efficiency. When two identical motors are connected on the same shaft the slip factor is the same for both motors. Therefore they will synchronise just as Lyn says. Each motor will take equal load (share the load equally).

If the two motors were not connected to the same shaft then you would have a concern with a difference in RPM. Even then it can be designed around. ■

Gary Blenkhorn

President - Bulk Handlng Technology Inc.

Email: garyblenkhorn@gmail.com

Linkedin Profile: http://www.linkedin.com/in/gary-blenkhorn-6286954b

Offering Conveyor Design Services, Conveyor Transfer Design Services and SolidWorks Design Services for equipment layouts.

Re: Synchronize Two Motors

If you are seeking a quantified answer, you need to assess your situation and decide.

This may assist, assuming you are using induction motors:

http://www.littelfuse.com/technical-...t%20Drives.pdf

Regards,

Lyle ■

Load Sharing W/ 2 Motors On One Shaft

This may assist, assuming you are using induction motors:

http://www.littelfuse.com/technical-...t%20Drives.pdf

Regards,

Lyle

Right Lyle,

The author gets close. The first note Mittya is correct. In fact the value is closer to 7% warrantied difference between drives with similar speed-torque and slip specifications, but, not manufactured at the same time with the same rotor laminates. In order to meet a closer slip-torque tolerance the rotor plates must be cut from the same metal sheets and oriented in the same manner.

When we did La Caridad, in 1976-77, we had Emerson Electric test the US Motors for their slip, after measure random motors, for their tolerance. We wanted to predict the load sharing among various drives on same shaft, different shafts with different power levels. The best Emerson would guaranty is about 5%. Westinghouse told us 7% for their wound rotor motor primary winding performance.

Given the above, there are numerous ways to force load sharing, that includes belt stretch between drives.

1. On La Caridad, we fitted primary voltage tap transformers to the drives that had a range up to 5% slip in 0.5% increments. This forces the drives to load share at one and only one point = 100% full load r 80% depending on client preference for ideal state. At, lower torque values, the secondary pulls more power and may force the primary drive (with dual pulley drives) into regeneration. This is OK, if you know what will happen with inverter driven motors, that also must be line-synch transfer achievable. Commissioning validated the theory.

Other options include:

2. Switching the behavior of the two drives with the higher slip nominated for the correct position. This should also be made in concert with correct pulley diameters. Larger pulley will always hog load. Must know the math to make belt elasticity, motor slip, reducer efficiency, et al. synch with expectations.

3. Fitting fluid coupling into proper fill levels between/on same shaft drives.

4. Think about 5% difference or 7% difference between drives on same shaft, this is not much, considering the cost of getting to 100%.

5. Others are not worth discussing here.

If you slip drives, the slip is discharged as heat to atmosphere. ■

Re: Synchronize Two Motors

I completed some quick numbers based on various assumptions, including: four pole induction motor (DOL / no secondary side adjustment), with one motor 100 % FLT @ 3 % slip and the other 100 % FLT @ -5 % of 3 % slip speed (~8 % slip), which yielded the “slower” (~8 % slip) motor will provide only 38 % FLT when the “faster” (3 % slip) motor is at 100 % FLT (i.e., you will only have 138 % “FLT”/ ~ power when you think you have 200 % “FLT” / ~ power)..

As a general rule induction motors “rigidly” attached to each other, theoretically do not share load well unless they possess “identical” torque speed characteristics or obtaining “100 %” of the combined installed power is not important – a visual inspection of the “100 % FLT” section of a typical motor torque speed curve confirms this (a small variance in speed, results in a significant change of available torque).

I have had this discussion with suppliers previously and based on my recollection I am wondering if the 5% variance may be in reference to “batch” of motors (over a course of a year or due to otherwise acceptable variances in manufacture etc, motor synchronous speed may vary by up to 5 %), i.e., it is relatively unlikely (though not impossible) to have two motors which vary by that much on the same shaft.

A conscious decision needs to be made (including considering what happens if a replacement motor, that has similar overall performance characteristics, though possesses inherently different torque speed characteristics from another supplier is used after a break down etc – maybe the answer is the end user is supplied with a suitable replacement or maybe adjustment provisions are provided).

As I said before (maybe a bit more bluntly then I could have, apologies) if the result matters, you (or you need to engage an appropriate someone) need to assess and make a decision.

Regards,

Lyle ■

Ac Motor Slip Accuracy

Slip Accuracy is measured as change in torque, not in slip. Slip error would lead to unacceptable power differences. ■

Synchronize Two Motors

Dear all!

Bucket elevator is on two drivers located symmetrically on the shaft. My question is how to synchronize this two motors? Because it will likely have a different loading.

Thank's! ■