The latest plant located in Holguin is destined for a large state construction company commissioned with the construction and completion of a tourist housing project. In fact, several projects are currently underway in Holguin, Guardalavaca and Pasquero as part of the Cuban government's tourism development plan, which provides for the construction of 19.000 rooms.It was this developmental goal that lead the state-run company to issue a call for tenders for the supply of a plant to process quarry aggregates suitable for concrete used in construction works. Among the foreign companies involved, Baioni was the most convincing in terms of capacity and experience and was awarded the contract for the tender.The requirements for processing and output have already been defined in advance. The aim was to ensure that the sand and gravel produced is suitable for the construction of the new tourist complex and meets all quality standards. The key to Baioni's success lies in two ways: firstly, in the high technological value of the products on offer and, secondly, in the environmental sustainability they offer the country.

Technological Functionality

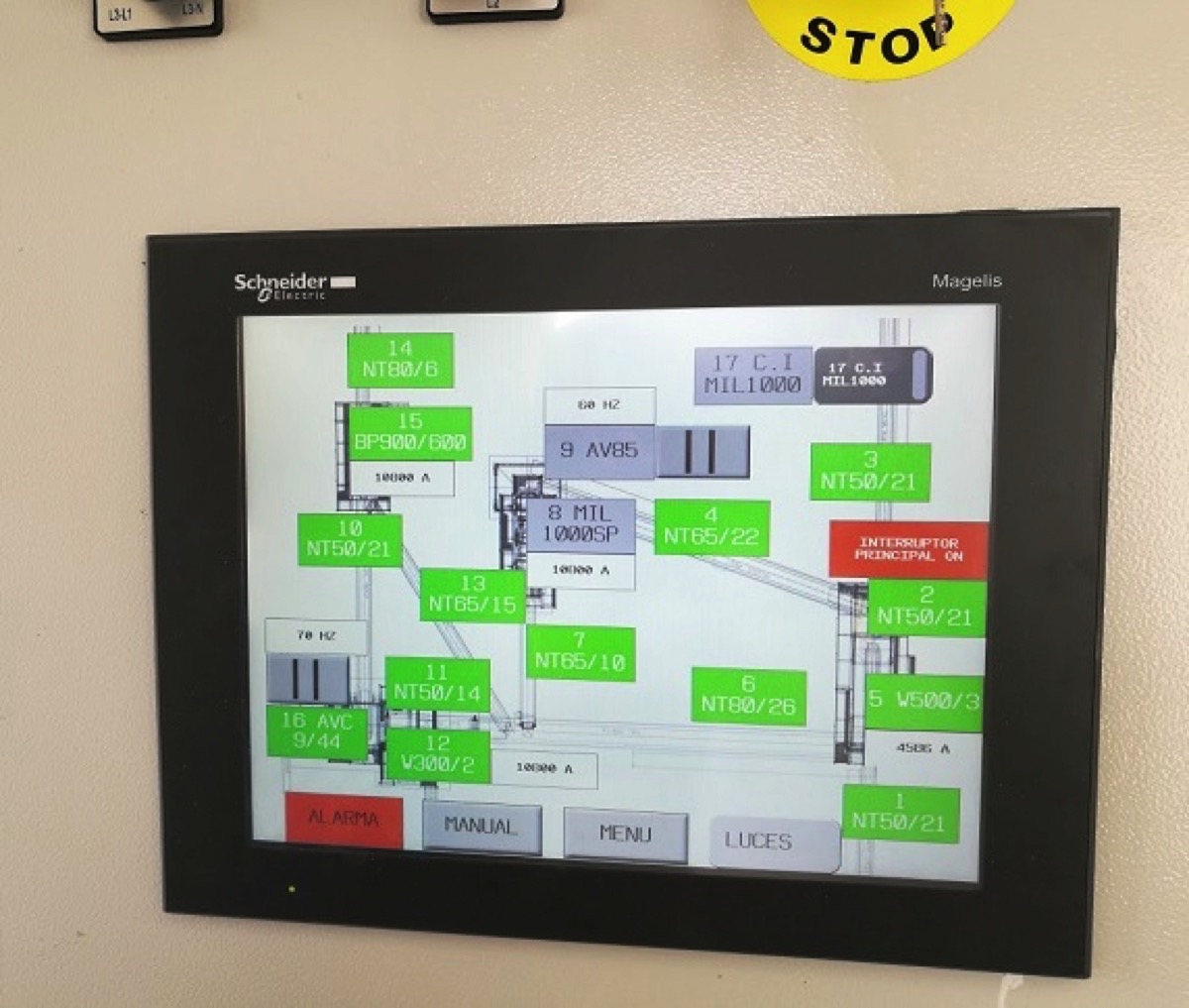

For this plant, Baioni has developed and manufactured an internal automated control system consisting of a series of sensors installed on the individual machines that support the operator during the various production steps, process all information received from the sensors and automatically control the flow of material to the feeders, maximising production and efficiency and minimising waste. Baioni's machinery has been set up in such a way that it can also be operated by less experienced staff in order to ensure maximum production yields and minimise downtimes. The benefits of this system range from the ability to automatically adapt to changes in materials used in the analysis of production costs (energy, maintenance, inefficiency, downtime), all of which are performed by a single automated monitoring and operating system. Baioni personally supervised the installation of the plant, which was carried out over a period of two months, and provided technical training for 12 operators and engineers.

Ecological Sustainability

The entire crushing and screening plant, including the automation system and controls, is equipped with energy-efficient motors and has dust collectors that reduce the environmental impact of plant operation. Baioni, together with the customer, aims to ensure the intelligent management of its machines by operators who respect both human and natural resources, using methods that have a zero impact on the environment.The plant, which is now operating in Holguin, comprises two crushing units: a primary crusher consisting of a BP series jaw crusher and a secondary crusher consisting of a modified MIL impact mill. The material leaving the pre-crusher unit is transported via a conveyor belt to the pre-screening unit, where fractions over 20 mm are separated with a W300 screen and fed back into the mill to ensure an even particle size distribution of the starting material. An additional triple-deck sieve W500 then separates the material dry into the desired grain size fractions (0-5 mm, 5-10 mm, 10-20 mm, +20 mm). "For us, this plant is further proof of Cuba's great interest in European technology, especially in the machines we manufacture" said Ulderico Baioni, President of Baioni Crushing Plants S.p.A. "We have signed important agreements between our company and the island's authorities for the next few years relating to the economic development of the entire country, including in the private sector. The development is supported by several collaborative projects supported by Sistema Italia in key sectors and the reconstruction of the Italian leadership following Hurricane Irma," Baioni concluded. ■