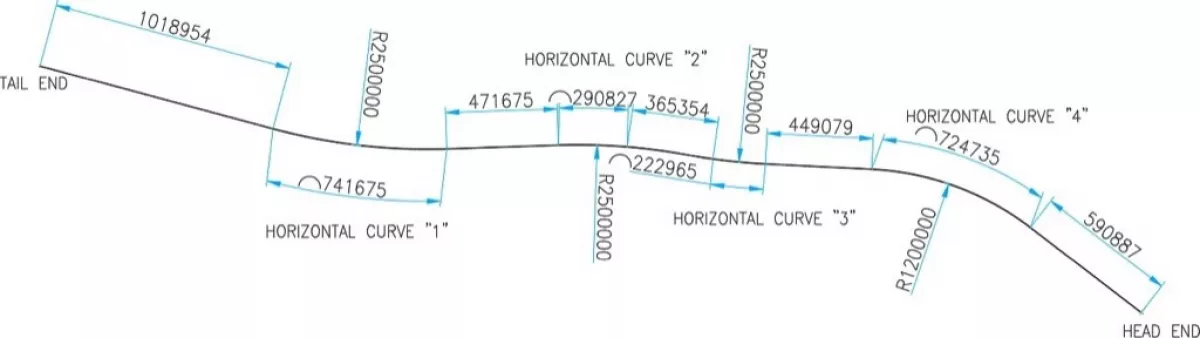

Horizontal Curves

This conveyor consists of four horizontal curves which eliminates the need for three additional transfer towers with structure, chutes, drives and electrical infrastructure, dust extraction and maintenance/operating personnel. This increases the reliability of the total belt system.

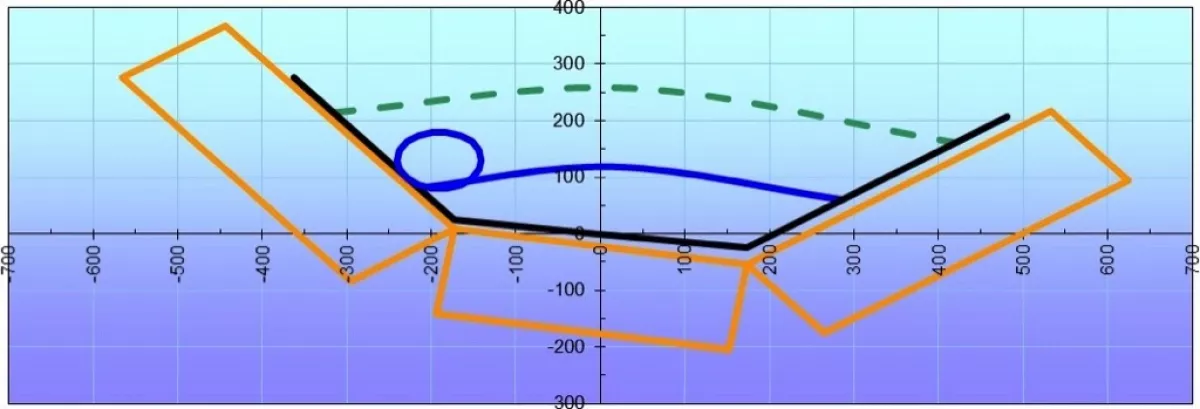

To prevent the runoff of the belt from the idlers, the idler stations in the horizontal curves have to be placed under a banking angle. A narrow centre idler and larger wing rolls is used to help control the belt drift in the horizontal curves. Reduced idlers spacing in the horizontal curves was also introduced to help with belt drift.

Dynamic curve analysis was carried out to predict the belt drift in the horizontal sections.

Triangular Pipe Gantries with Traveling Maintenance Trolley

The overland gantries are fabricated from standard tube sections on to which conveyor technological structures are mounted. A significant feature of this gantry design is the absence of access walkways throughout length of the conveyor. Removing the need for access walkways reduced the overall structural cost. The tubular structure allows greater spans when compared to conventional gantry profile steel design.

Fig. 8: Conveyor crossing gorge at 50m elevation

|

Fig. 9: Maintenance trolley to do maintenance along the conveyor

|

The trolley automatically provides full access to the conveyor belt for inspection and maintenance purposes. The trolley is used by the maintenance personnel to travel the full extent of the conveyor belt on a daily basis. So, for long belt Conveyors, this is the best way to eliminate walkway access throughout the length of the conveyor.

3-Roll Return Side Idlers

To help control belt displacement in the horizontal curves, a three-roll idler set is used on the return side of the conveyor. The use of a 3-roll return set increases the longitudinal stiffness of the belt. Therefore, the belt flap and resonance are typically much better than a conventional two-roll VEE return system.

Furthermore, the idlers can be pitched farther apart, which offsets the cost of additional rolls. For example, on a conveyor with a 4 m VEE return spacing, a three-roll set could use 8 m. Therefore a smaller number of rolls and idler frames are required.