The decision in favor of the two ZSK extruders was influenced by the long-standing partnership based on trust between Delta Kunststoffe AG and Coperion, as well as the quality of the extruder. Delta Kunststoffe AG equipped its production facilities in the past with several ZSK extruders from Coperion. With the new extruders, Delta will be able to work even more flexibly and efficiently – particularly when producing small to medium batch sizes.

Long-standing, successful Partnership

Delta Kunststoffe AG is a specialist in the production of color masterbatches, electrically conductive compounds and individual, customized special compounds. Delta purchased its first Coperion extruder in 2005, a ZSK 58 Mc PLUS compact for producing masterbatches.Since that time, a partnership based on trust has developed between the two companies. “We are highly satisfied with the partnership, the quality of the machines and our end product. This is why we decided to rely on Coperion’s experience again and expand our machine park by two state-of-the-art processing plants: the ZSK 26 Mc18 and the ZSK 45 Mc18 compact. They deliver dependable, top-quality products,” said Andreas Bäßler, Managing Director of Delta Kunststoffe AG.Coperion’s service in the past and its process-related experience and advice were key to Delta’s decision-making process. In addition, the extensive preliminary trials at the Coperion test lab in Stuttgart achieved the desired results.

ZSK extruder for highest quality requirements and successful energy management

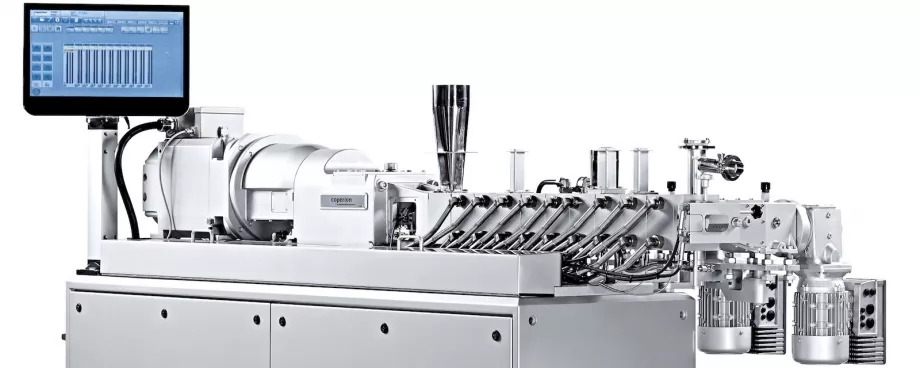

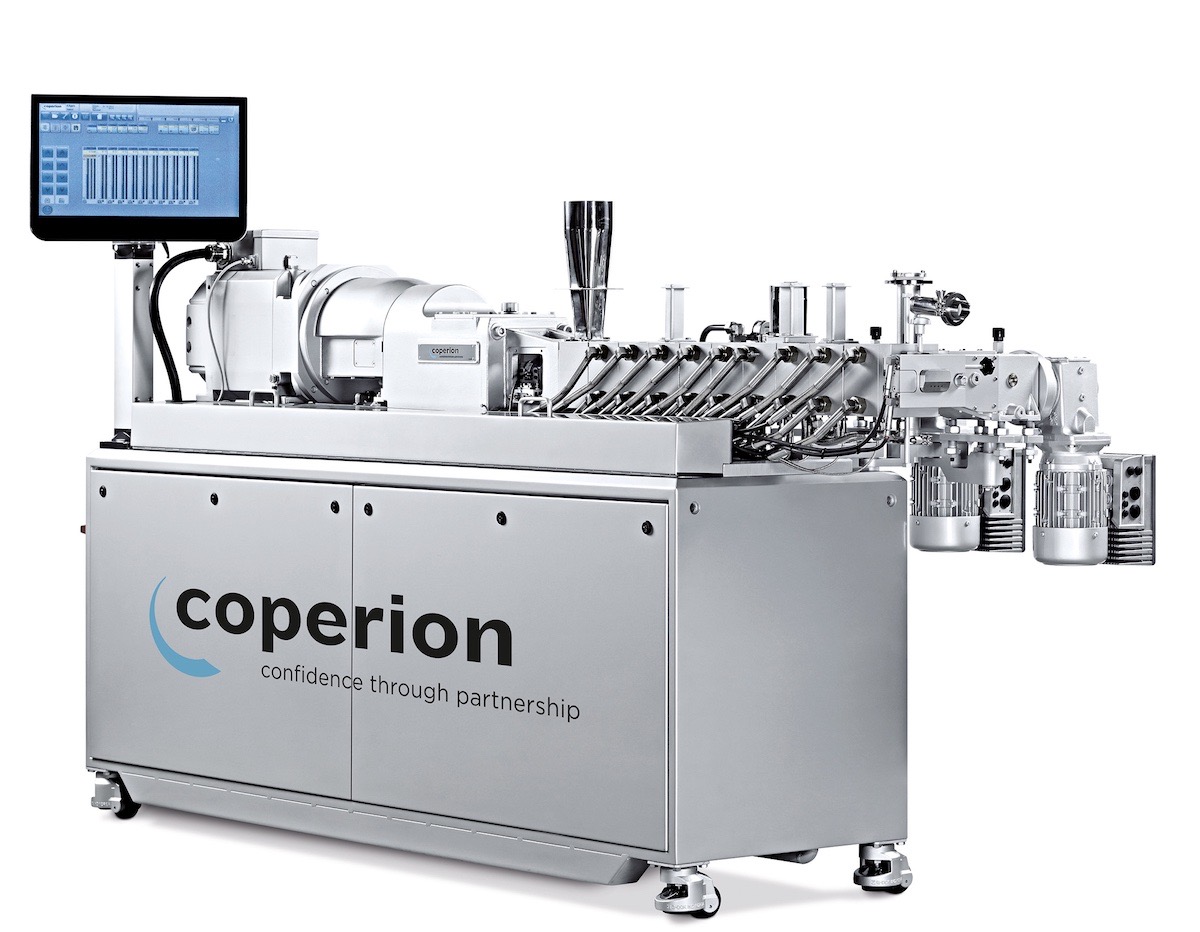

Coperion’s ZSK Mc18 twin screw extruder series consistently delivers high product quality at maximum throughput rates. ZSK extruders feature high specific torques that enable a high screw filling level and in turn, energy-saving, gentle product handling and correspondingly low melt temperatures. And the decrease in specific energy consumption leads to an increase in energy efficiency and lower energy costs.

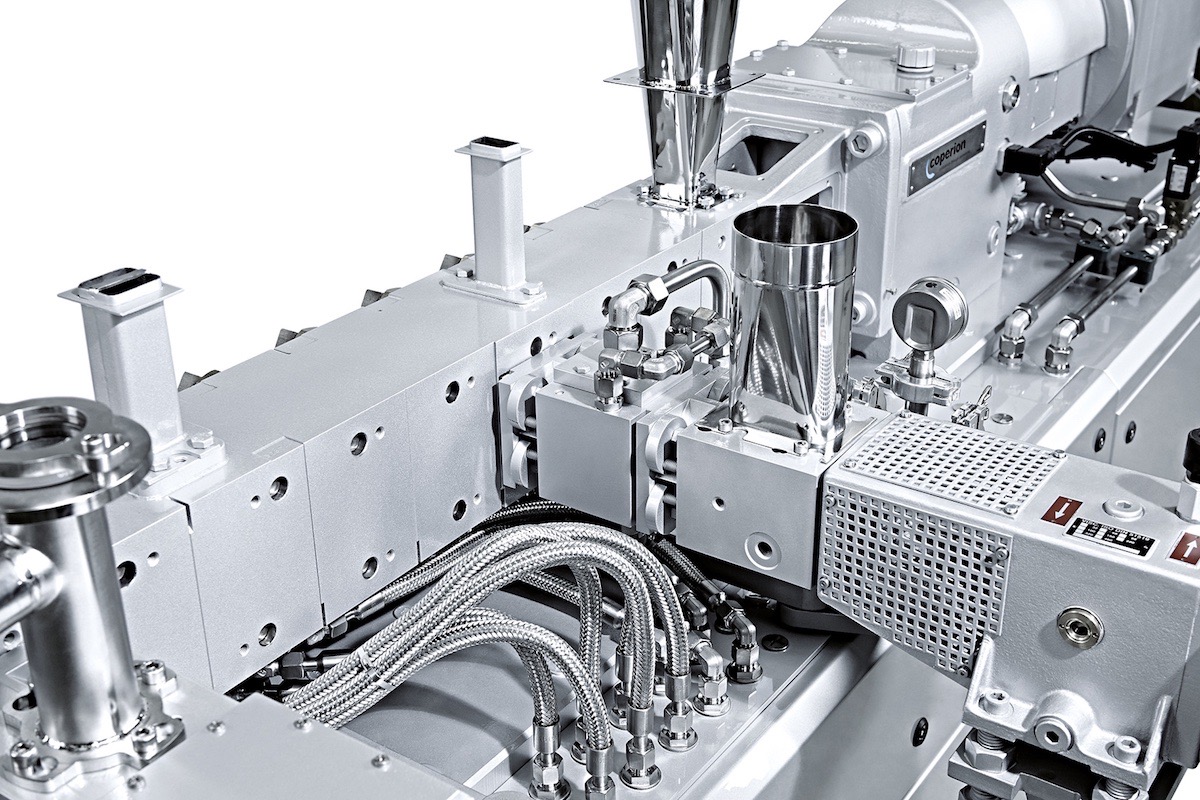

Thanks to numerous quick-change features, the extruder has impressive flexibility. It’s designed to be easily accessible and simple to clean, which ensures quick product changes. Twin screw side feeders are used to feed additives in powder or granular form into the process section of the extruder. For quick, effective cleaning, they can be removed from the process section in a few steps. In combination with its gentle product handling and self-wiping screw profile, the ZSK Mc18 twin screw extruder is ideal for the production of top-quality masterbatches.Please also visit: Meet our bulk-online Leader: Coperion and Coperion K-Tron ■