Processing highly heterogeneous material flows - for example from sewage treatment plants, power stations, recycling plants or mining - so that they can be reused safely and marketably is a highly demanding process engineering task. Application-specific Ploughshare® mixers from Lödige Maschinenbau deliver good results for sludges, dusts and other bulk materials.

Sewage Sludge Treatment in one of Germany's largest Sewage Treatment Plants

For example, 220,000 tons of sewage sludge are produced every year at the Bottrop sewage treatment plant and surrounding sewage treatment plants in the Emschergenossenschaft and Lippeverband association area. To ensure an optimal thermal process, this sewage sludge must be conditioned before incineration. The focus here is on the dry substance content (TR content). A certain mixing ratio of moist and dried sewage sludge and good homogeneity are therefore crucial for the quality of thermal utilization. In addition, there are requirements for the structure of the material: a defined lumpiness must be achieved for an optimal thermal process.

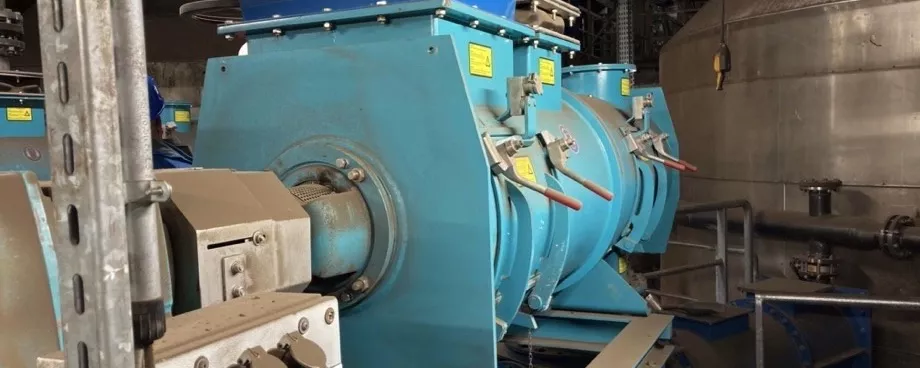

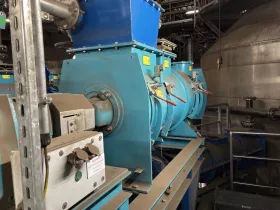

Ploughshare® mixer type KM 600 DW

Mixing and structuring in a Ploughshare® mixer type KM DW from Lödige Maschinenbau proved to be a suitable process for conditioning the sewage sludge. The machine is designed for continuous operation and is based on the fluidized bed process introduced to industrial mixing technology by Lödige Maschinenbau, which ensures very good mixing: the specially developed paddles rotate close to the wall in a horizontal drum, creating a fluidized bed. The process enables a high degree of homogeneity with constant reproducibility.

Specifically, two KM 600 DW Ploughshare® mixers are used at the Bottrop wastewater treatment plant. Their mixing drums each have a volume of 600 liters and are designed for a filling level of 50 percent. The mixers are continuously fed with moist and partially dried sewage sludge via an automated transport process. The drying process was also developed with a focus on sustainability: The solar-thermal drying plant specially built for pre-treatment is one of the first of its kind in Europe.

Visit Lödige Maschinenbau at IFAT 2024: Stand A2-129.

■