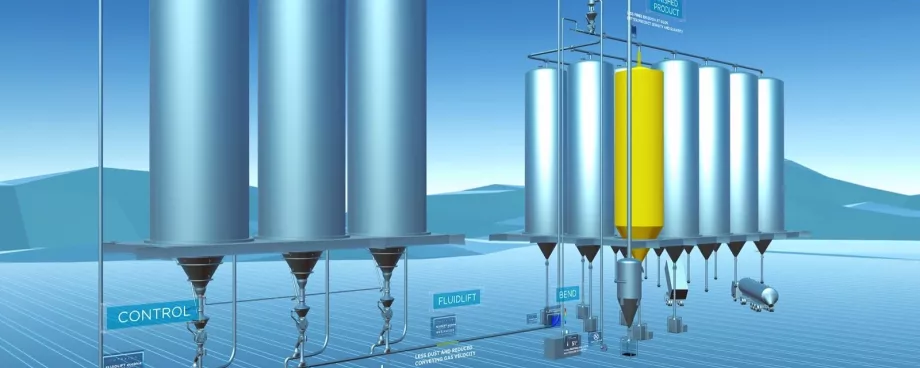

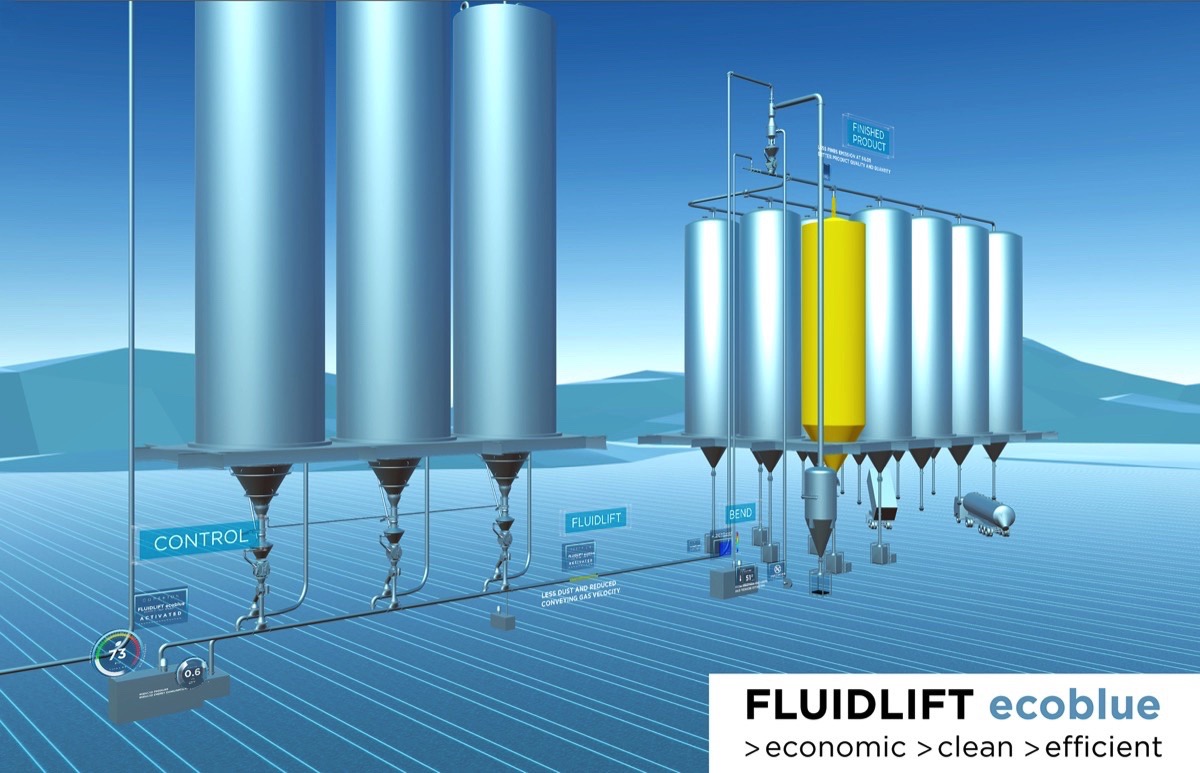

Its lower power consumption also allows plastics manufacturers and compounders to reduce their costs or correspondingly increase their throughput. Under industrial conditions it has been possible to reduce the formation of dust and streamers by between 50% and 98%, at the same time lowering the pressure loss in the conveyor system and hence the necessary energy consumption by from 17% to 35%. Coperion will present its new process, which is suitable for both, new installations and retrofitting existing systems, for the first time worldwide on booth W729, West Hall Level 2 at NPE 2018, which will be held May 7 to 11 in Orlando, Florida, USA.

(Image: Coperion, Weingarten/Germany)

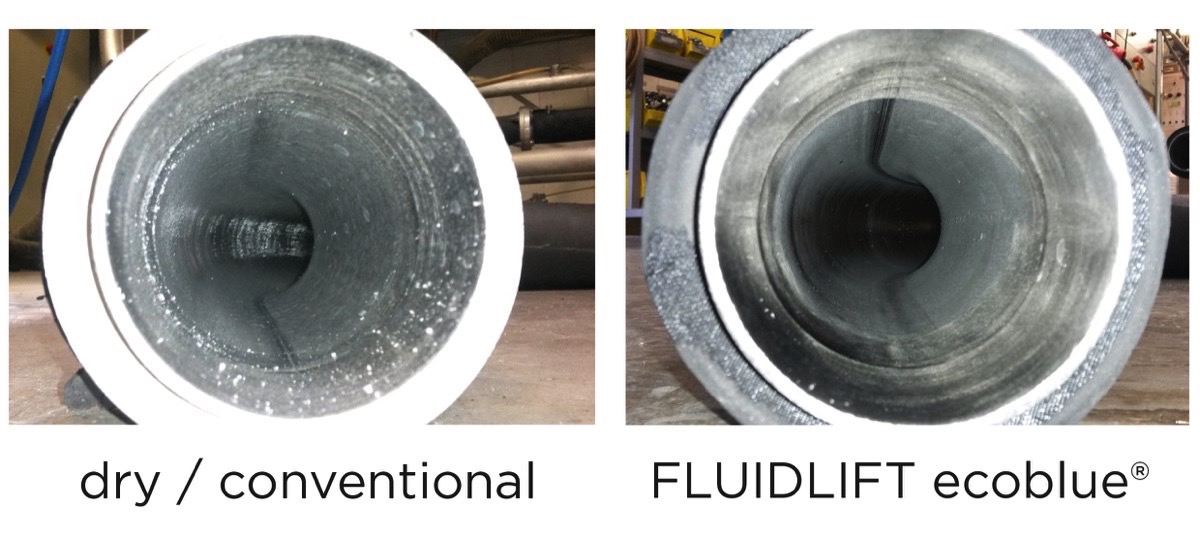

The key to significantly reducing both, attrition and pressure loss – the pressure difference between product feed and product delivery – is a controlled increase in the relative humidity of the conveying gas. The primary concern of the extensive investigations which were carried out while developing FLUIDLIFT ecoblue® was to prevent any impairment of the end product by minimizing the amount of moisture introduced and subsequently reliably removing it. The result of this is that the granulate can be conveyed at a very low velocity, so friction between the grains and at the wall of the pipe is substantially lower than in previous designs. Ultimately, this new process ensures a dry, almost dust-free end product without any need for complex additional measures.

In general, FLUIDLIFT ecoblue® offers a advantageous alternative wherever attrition-sensitive products are conveyed and the generation of dust is undesirable or might even interfere with subsequent processing of the manufactured pellets. This extends the range of applications from bulk plastics to application-specific high-performance compounds. Our new process proves to be particularly advantageous when handling products for upmarket technological applications such as films, high-purity granulates and optical components.Christian Soretz, Head of Product Management for Materials Handling at Coperion, explains: “FLUIDLIFT ecoblue® effectively combats the problem of conventional pneumatic conveying systems that generate varying but usually considerable amounts of attrition in the form of dust or streamers. These may form layers on the inside of the pipes and accumulations of dust in reception bins and silos, which can spontaneously become released and lead to blockages or other deleterious effects. It is therefore necessary to remove all forms of attrition, which often costs a considerable amount of manpower and time and also reduces the production volume. In cases where material also has to be elutriated prior to processing, the production costs rise even further. FLUIDLIFT ecoblue® minimizes attrition and thus prevents as far as possible the formation of dust accumulation. This helps plastics manufacturers to achieve consistently high quality and attractive margins. The potential cost reductions and the increased throughput that can be achieved guarantee a rapid return on investment.”Visit Coperion at the NPE 2018, Orlando (FL), United States, from 7 to 11 May 2018 at Booth W729, West Hall Level 2.More information on CoperionGoogle Search – WebGoogle Search – ImagesCoperion on the PortalCoperion Videos on bulk-online

See also:

■