Ceramic Ball Valves Applied To Pulverized Coal Injection System

Structural ceramic ball valves are applicable to various acid, alkaline or saline solutions, gaseous media, etc. Hard sealing ball valves can also be used in media with particles and fibers.

Currently, in high furnace of metallurgy technique, techniques of high wind, high temperature, refined steel, injection oxygen enrichment have been widely used to save cost and increase production. Furnace injection techniques have been widely used for some places where lack of coke and small high furnace. Actually, for places where does not lack of coke, high furnace injection has not been adopted. Along with lacking of coke, cost increasing of coke meanwhile ceramic lined pipe, elbow and valves are growing maturely, more and more steel factories adopt high furnace injection techniques.

1. Meaning of pulverized coal injection

Pulverized coal injection is an important revolution for high furnace metallurgy. Pulverized coal injection refers that injecting refined coal from high furnace to replace coke and offer heat and reducer. The significance of pulverized coal injection list as below:

1) Using cheap coal to replace expensive furnace coke, which can reduce coke ratio and cost of metallurgy significantly.

2) Pulverized coal injection could be a way of adjusting furnace conditions.

3) Pulverized coal injection could adjust furnace working conditions and make furnace work smoothly.

4) It can increase wind temperature and create oxygen-enriched blast. Coal injection could reduce theoretical burring temperature before wind.

After High furnace injects coal fines, coal gas increases meanwhile it will consume heat to warm coal fines.

The amount heat that injecting coal fines brings is a few. When coke enters tuyere, coke will be well heated up to 1450~1500.The temperature of coal fines will be less than 100.

The hydrocarbon in the coal fines needs heat to decompose.

The coal fines have more hydrogen than coke brings. Hydrogen increases reducing power and penetration diffusion capacity, which will be helpful for ore reduction and improve high furnace operation.

Coal injection replace partial coke, which will relieve lack of coke and reduce investments of building coking plant

Currently ceramic is applied for pipe and valves, which have solved abrasive problem of coal injection, reduce cost and increase working performance.

2. Introduction of pulverized coal injection process

It mainly includes two procedures: coal fines making and injection:

1) Coal fines producing system adopt vertical middle-speed fast grinding. Electric motor actuated reducer makes millstone rotated. Raw material will be sent to millstone from feed port of feeder. Under pressure of centrifugal force, raw material will enter roller way from all around and become powder with power of roller way.

2) Under weight of roller way and pressure device, raw material will become powder. Because there is not only rolling between roller way and millstone, raw material will get several stresses, which will increase grinding capacity and efficiency. Hot air enters tuyere and millstone from bottom body.

Because there is air distributing ring in the gap of rotated millstone and bottom body, it can be evenly distributed in the millstone along with air of air distributing ring.

3) Grinded material will be blew up. Qualified powder will go out along with air and these collected by dust collector are finished products. Bigger powder will be redistributed in the millstone under effect of air distributing ring and get reground. This procedure will cycle and recycle all the time. These small steel pieces mixed with material in the millstone will be blew out from rotated millstone and fall down on the bleeding hole. Foreign material will be cleaned as long as bleeding hole is open periodically.

Injection system make us of high pressure air to inject coal fines from injection tank to high furnace directly.

During this procedure, high-speed col fines will abrade elbow, pipe and valves seriously, so all pipe, elbow and vales of injection system should be lined with ceramic. Usually fully lined ceramic ball valveare applied. Structure ceramic has performance of high hardness, high strength, anti-corrosive and anti-abrasive. After grinding seat and ball precisely, ceramic ball valvescould reach zero leakage, which can make sure of excellent sealing performance and have a very long service life under seriously erosion of high-speed coal fines.

■

■

Ceramic Ball Valve

Structural ceramic ball valves are applicable to various acid, alkaline or saline solutions, gaseous media, etc. Hard sealing ball valves can also be used in media with particles and fibers.

FUVALVE ceramic ball valve ,the property is very excellent for abrasive applications. ■

Re: Ceramic Lined Valves

Structural ceramic ball valves are applicable to various acid, alkaline or saline solutions, gaseous media, etc. Hard sealing ball valves can also be used in media with particles and fibers.

Full lined ceramic butterfly valve for NH4NO3 solutions

The ceramic lined Control Butterfly Valve with heating jacket for the medium of Ammonium nitrate NH4NO3 and molten alum NH4 Al(SO4)2. 12H2O which operating temperature is 128°C with pressure max 13 bar.The body and disc material requested 304L full lined ceramics.As the Ambient temperature is -28 deg C,there is steam a at 175 deg C for heating jacket.

Ceramic lined valves

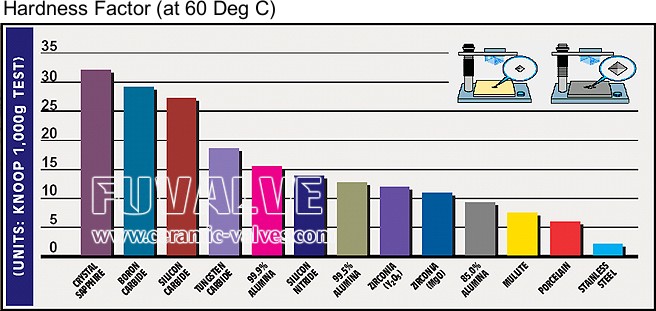

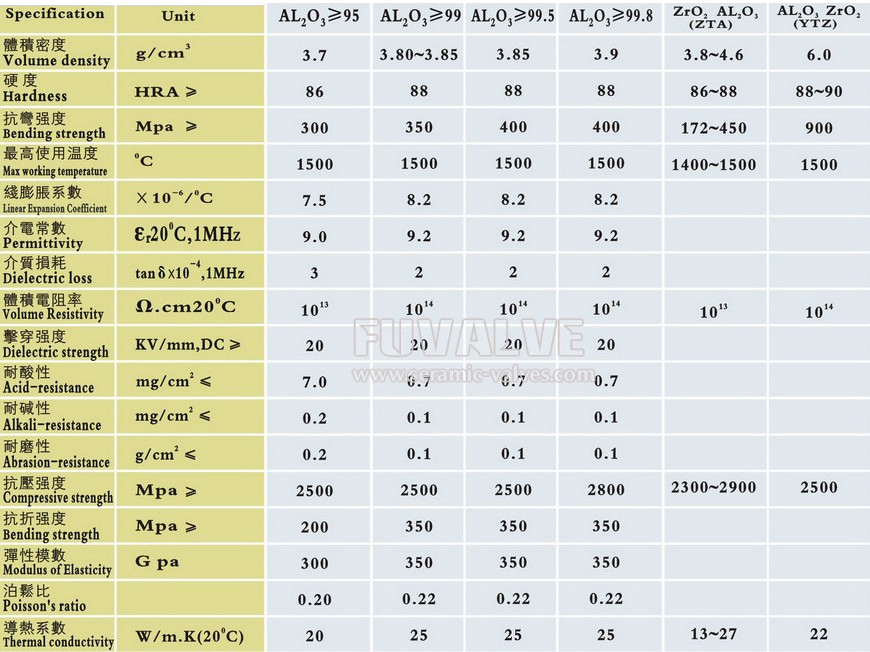

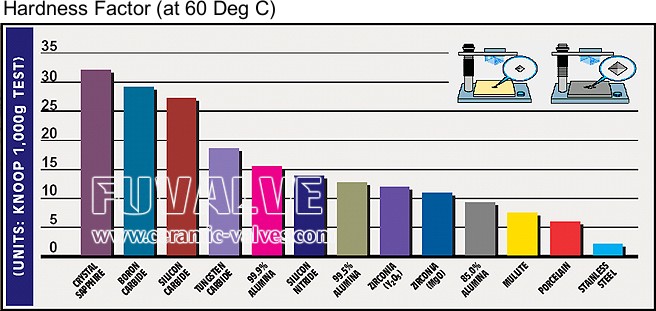

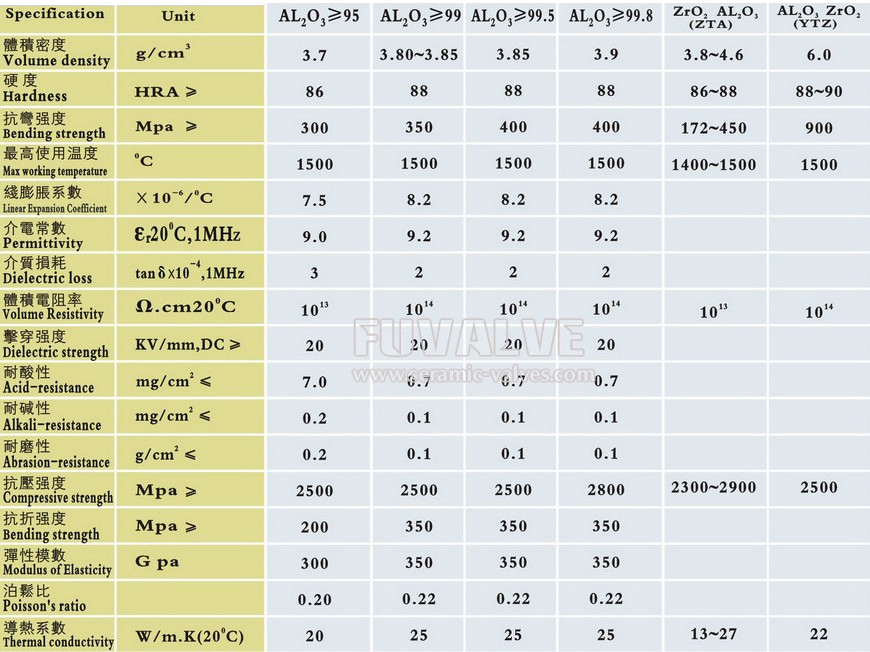

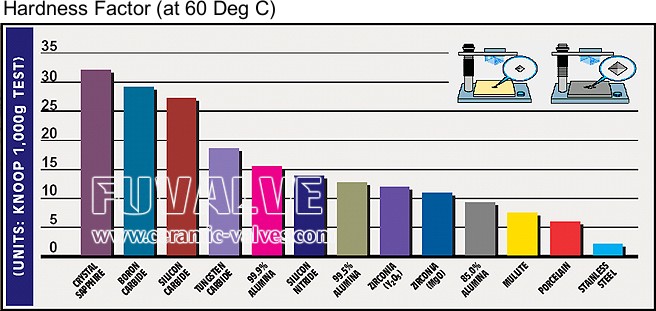

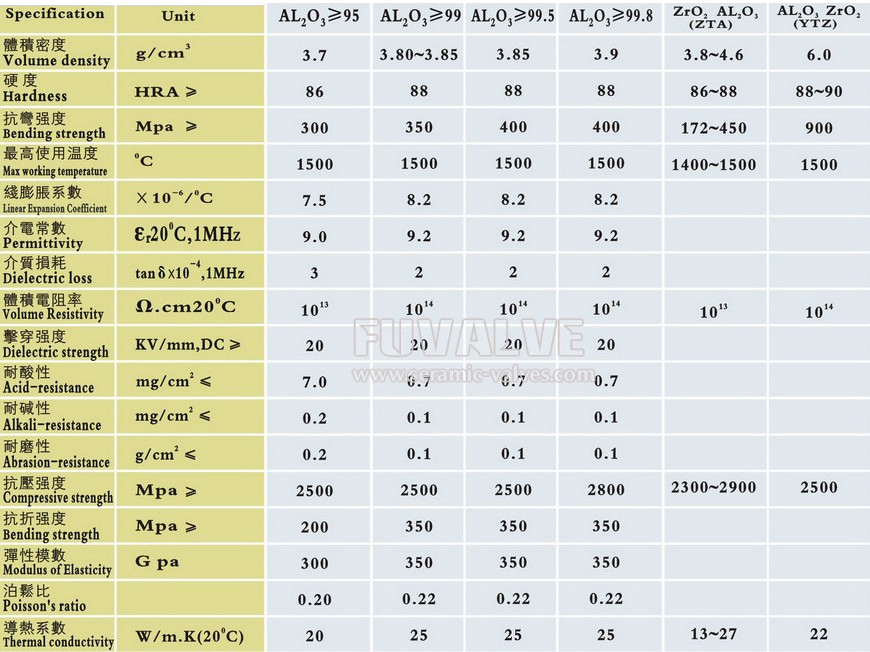

As a abrasion resistant and corrosion resistant valve,ceramic lined ball valve has very excellent performace for abrasive mediums and corrosive mediums.The FUV ceramic lined valve has been used in quartz pneumatic conveying,coal powder pneumatic conveying,Silica powder pneumatic conveying,Lime powder pneumatic conveying,Calcium cyanamide pneumatic conveying and etc. From the below material property you'll find the hardness,strength and other performance of the different structure ceramics. FUV Structural Ceramic Ball Valves(Al2O3 or ZrO2 Ceramic) Advantages of structural ceramic ball valves include hi-economy, long life (2~4 times of Titanium Valves), increase resistance to corrosion, high temperature, wear and erosion etc.. They are commonly used in transportation systems of various acid, alkaline or saline gases, solutions, high working temperature steams and slurries, in the lines of oil industry, metallurgy, papermaking, power station, refinery, etc. Structural ceramic ball valves are the ideal substitute for titanium and monel valves in corrosive environments. There are four types of driving performances, manual, pneumatic, pneumatic-spring return and electric. Various special valves can be designed on demand. Furthermore, various high wear-resistant, corrosion-resistant and high temperature-resistant ceramic components, hydraulic pressure sealing components can be provided as well. Properties of FUVALVE Structural Ceramic Ball Valves Typical properties of structural ceramic ball valves include: Wear and corrosion resistance The valve ball, valve seat and inner lining are all made of structural ceramics with hardness of HRA87 or above. So structural ceramic ball valves can withstand the impact of Hi-speed liquids and hard grains, displaying excellent performance on wear and corrosion resistance. Corrosion resistance The valve ball, valve seat and the inner lining are all made of structural ceramics. The structural ceramics have excellent corrosion-resistance, except to glass-liquor and hydrofluoric acid. Long working life The static pressure test showed no leakage after 10000 times opening-closing. Wide-range of applications

Structural ceramic ball valves are applicable to various acid, alkaline or saline solutions, gaseous media, etc. Hard sealing ball valves can also be used in media with particles and fibers.

href="https://forum.bulk-online.com/attachment.php?attachmentid=44076&d=1433499098" id="attachment44076" rel="Lightbox86143" target="blank"> ■

■