One Question

Dear Mr. Ruta Zhu,

is this a continuous conveying from a storage bunker / bin / silo or else, or is this a discontinuous conveying with the load coming from a crusher / feeder system (throughput varying in a large margin) ?

Regards

R. ■

Re: High-Angle Limestone Pipe Conveyor Project

Hello Mr. Roland Heilmann,

We have set the continuous feeding for pipe conveyor system.

Thanks,

Ruta ■

High Lift Slope Pipe Conveyor

Dar Ruta,

Conveyor Dynamics, Inc. (CDI) has the experience you seek and have done many pipe conveyor belts in China. Your request for large downhill slope is of special interest in that CDI can couple Discrete Element Modeling (DEM), Finite Element Analysis (FEA), belt flexibility at and between idlers with any granular material composition that will act to deform the belt.

These tools provide necessary understanding of the belt behavior to quantify its deformation characterisitics between idlers and forces on the idlers as well as the interaction with stopping and starting a loaded or partially loaded belt.

I suspect CDI is the only company that already possesses the means to integrate the pipe conveyor geometry, its belt properties, and with crushed limestone granular action within a pipe conveyor.

We see no problem in specifying the proper design to meet your demanding material properties, slope gradient, and tonnage. CDI are also specialist in large downhill conveyors with complex braking systems. We have designed the world's largers downhill conveyor brakes at Los Pelambres, also at Collahuasi, and were involved at the El Abra downhill systems.

Please contact the undersigned for any assistance. ■

Re: High-Angle Limestone Pipe Conveyor Project

Dear Nordell,

Hello, i'm pleased to your attention for our project and hope to recieve from your help,

can you tell me how can i contact to you it is more convenient?

Ruta ■

High Decline Pipe Conveyor

Dear Mr. Zhu,

Best to make correspondence to our Dr. Yijun Zhang. He is our pipe conveyor specialist. I believe he is able to provide you all the information you will need. See contact details below

Best Wishes ■

Re: High-Angle Limestone Pipe Conveyor Project

The latest path breaking application is a 16.4 km long belt (8,172 m center distance) for the conveyance of hot clinker from a cement factory to the port on the upper run of the conveyor, and coal and limestone from the port to the factory on the bottom run. The diameter of the Both belt covers are equipped cords to achieve the optimum restoring force. The smallest curve radius is 300 m. The path of the conveyor belt is underneath streets and buildings. ■

Dsi Snake Sandwich High Angle Conveyor

Mr. Zhu,

Please contact me at aduncan@dossantosintl.com. We are happy to review your project and offer you a solution with our DSI Snake Sandwich High Angle Conveyor. You can see more at our web site www.dossantosintl.com.

Regards,

Amy Duncan ■

Re: High-Angle Limestone Pipe Conveyor Project

Dear Sir,

This conveying systems consists of a pipe belt conveyor conveyor and a a deep trough belt conveyor.

The pipe belt conveyor:

1. Horizontal length 1288m;

2. Lifting height -492m;

3. Conveying capacity 700t/h;

4. Conveying materials limestone;

5. Packing density1.45t/m3;

6. Pipe diameter 300mm(belt width 1150mm);

7. Belt velocity 4m/s;

8. Driving arrangment Two drive pulley at tail.

The deep trough belt conveyor:

1. Horizontal length 2576m;

2. Lifting height -296m;

3. Conveying capacity 700t/h;

4. Conveying materials limestone;

5. Packing density1.45t/m3;

6. belt width 1000mm;

7. Belt velocity 4m/s;

8. Driving arrangment Two drive pulley at tail.

Zigong Conveying Machine Group Co.,Ltd.

No.1 Dayandong Ziliujing Ditrict Zigong Sichuan Province China

643000

e-mail long650101@163.com ■

Glory Glory ...

In the UAE, RAK-ROK used a glory hole to overcome the situation. Your tonnage is a lot less so I suspect you might have difficulty blasting a small enough hole. It is a trade off between the outer rim and the pitch of the slipway. Kallenborn maybe still publish their handbook which gives great insight into staple shaft bunker dimensions.

European contractors do not like to do such work anymore (Health & Safety while working abroad etc.) so you would need someone like ShaftSinkers out of Jo'burg. A glory hole reduces the downdip. In RAK-ROK the outbye was quite level and dropped onto an intermediate pile which then carried the job into the plant.

If it sounds like I think you have rushed at the job and got stuck with a conveying problem that maybe doesn't need to be there: it's because I do.

Do you need a 'path breaking' installation when you are only conveying stone downhill? If you can feed the downstream pipe conveyor with anything approaching 300tph then you are selling product while you raise bore the glory hole. ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

High-Angle Limestone Pipe Conveyor Project

Ruta,

A pipe conveyor is not a high angle conveyor unless you provide internal cleats. In such a case the system becomes complicated and cannot be scraped clean. Our sandwich belt high angle conveyor system will prove technically advantageous and very economical, being able to follow closely the natural topography allowing typically for a simple stringer type structure. Our system uses all conventional conveyor components and equipment including smooth surfaced rubber belts that can be scraped clean continuously. Send us your requirements if you wish to pursue this.

Joe Dos Santos ■

High Anlge Conveying

A critical value is the particle size distribution. What is size passing for largest 2% by volume and smallest or below 10% passing.

This will give more understanding on what method will likely be the better choice. ■

Difference Of Opinion With Downhill Conveyor Design - Pipe Vs. …

This conveying systems consists of a pipe belt conveyor conveyor and a a deep trough belt conveyor.

The pipe belt conveyor:

1. Horizontal length 1288m;

2. Lifting height -492m;

3. Conveying capacity 700t/h;

4. Conveying materials limestone;

5. Packing density1.45t/m3;

6. Pipe diameter 300mm(belt width 1150mm);

7. Belt velocity 4m/s;

8. Driving arrangment Two drive pulley at tail.

The deep trough belt conveyor:

1. Horizontal length 2576m;

2. Lifting height -296m;

3. Conveying capacity 700t/h;

4. Conveying materials limestone;

5. Packing density1.45t/m3;

6. belt width 1000mm;

7. Belt velocity 4m/s;

8. Driving arrangment Two drive pulley at tail.

Zigong Conveying Machine Group Co.,Ltd.

No.1 Dayandong Ziliujing Ditrict Zigong Sichuan Province China

643000

e-mail long650101@163.com

The above input are quite conservative. A conventional trough belt can do the specifications you outline for the pipe conveyor. The maximum slope is only 20.8 degrees. If you design for proper confinining stress/fricition between particles and particles to belt friction, the material will not flush with medium braking action. No spillage, no sliding, and no rolling free will occur. Power is a moderate 1000 kW. ST rating may be reduced depending on ambient temperature range. Belt width can be reduced for both pipe and trough. Trough reduction includes binding or interlocking rocks and proving the load is stable with DEM analysis. We did another project in China for similar steep downhill. Model results can be proven with scale model.

We need temperature range to assess range of belt drag, although lift is dominant. ■

Thread Connection??

Dear Mr Ximrong Gong,

Does Mr. Ruta Zhu work for Zigong? Are the Xigong and Mr. Zhu's specifications related to the same conveyor?

If so, did I meet Mr. Zhu in China at your factory - site tour?

Is this the same project CCCC is bidding on? I thought the particle size was much larger. This was a steep decline feeding base of dam. ■

Re: High-Angle Limestone Pipe Conveyor Project

Does Mr. Ruta Zhu work for Zigong? Are the Xigong and Mr. Zhu's specifications related to the same conveyor?

If so, did I meet Mr. Zhu in China at your factory - site tour?

Is this the same project CCCC is bidding on? I thought the particle size was much larger. This was a steep decline feeding base of dam.

Mr.Lawrence Nordell,

Thank you very much. Mr.Rutazhu should Tianjin mining co.,Ltd. ■

Re: High-Angle Limestone Pipe Conveyor Project

href="https://forum.bulk-online.com/attachment.php?attachmentid=36918&d=1374884307" id="attachment36918" rel="Lightbox80034" target="blank">

href="https://forum.bulk-online.com/attachment.php?attachmentid=36917&d=1374884250" id="attachment36917" rel="Lightbox80034" target="blank">■

High-Angle Limestone Pipe Conveyor Project

The original post that began this thread mentions high angle requirements of 30 degrees. This has been ignored by all replies except for mine. Is there a high angle requirement or not?

Joe Dos Santos ■

High Angle Conveying

Joe,

Your are right. However, when the thread starter or another answering the thread starter, the slope values changed. Thus, some reading the actuals, changed accordingly. 20 degree is not 30 degree or better 38 degrees. So, how do we respond? ■

High-Angle Limestone Pipe Conveyor Project

Larry,

I went back to the original post below:

"We'll make a conveyed limestone project in China, but have a little trouble in the project,because part area of conveyor line site's downhill angle over 31 degree, so i hope we can find a partner of enough experience for solved this question, ........................................."

I was not able to open the preliminary layout that was cited.

I then followed the discussion until now and could not find where Mr. Ruta changed the requirements.

Mr. Ruta, please clarify the requirements. What is the required conveying angle? What is the complete profile?

Joe Dos Santos ■

High-Angle Limestone Pipe Conveyor Project

OK, I did open the file with the profile, that was attached to the original post. This is ideal for a DSI GPS (gently pressed sandwich) system. Because the GPS can follow the topography closely great savings will be realized in the structural support system which will be largely of simply stringer structure. The risk due to the slope angle is eliminated.

Accommodating the angle limitations of other systems will result in significant elevated structure and bents.

Joe Dos Santos ■

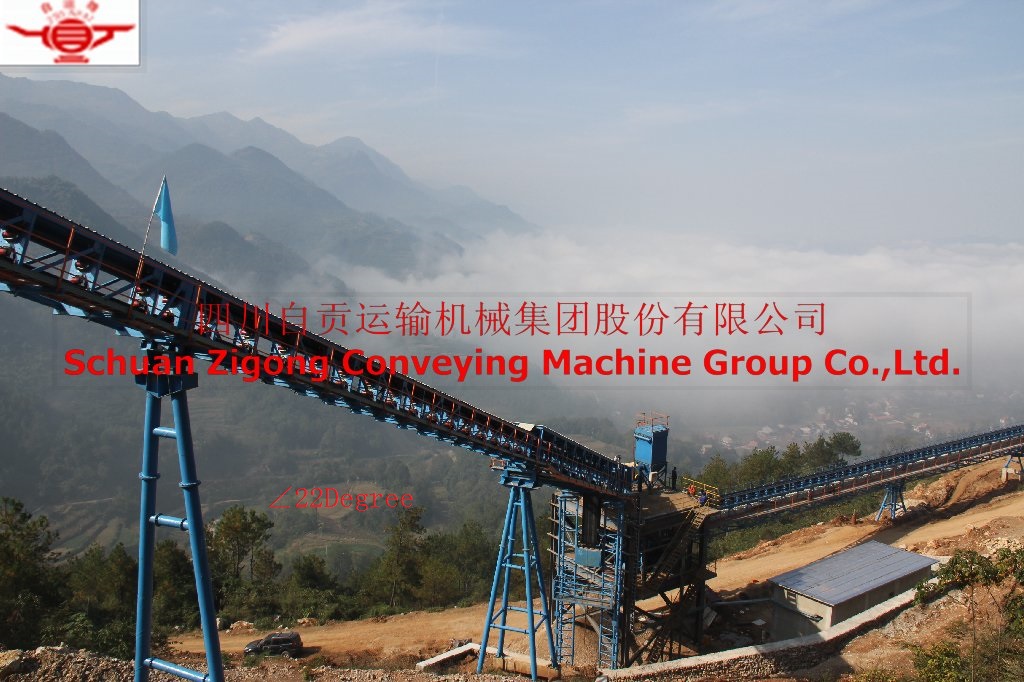

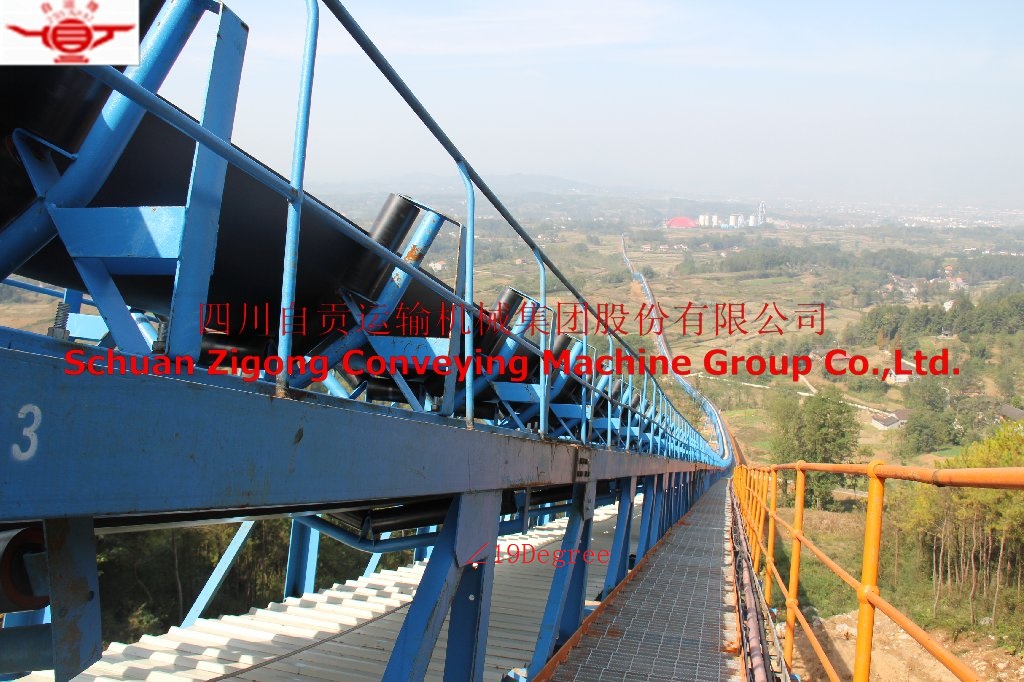

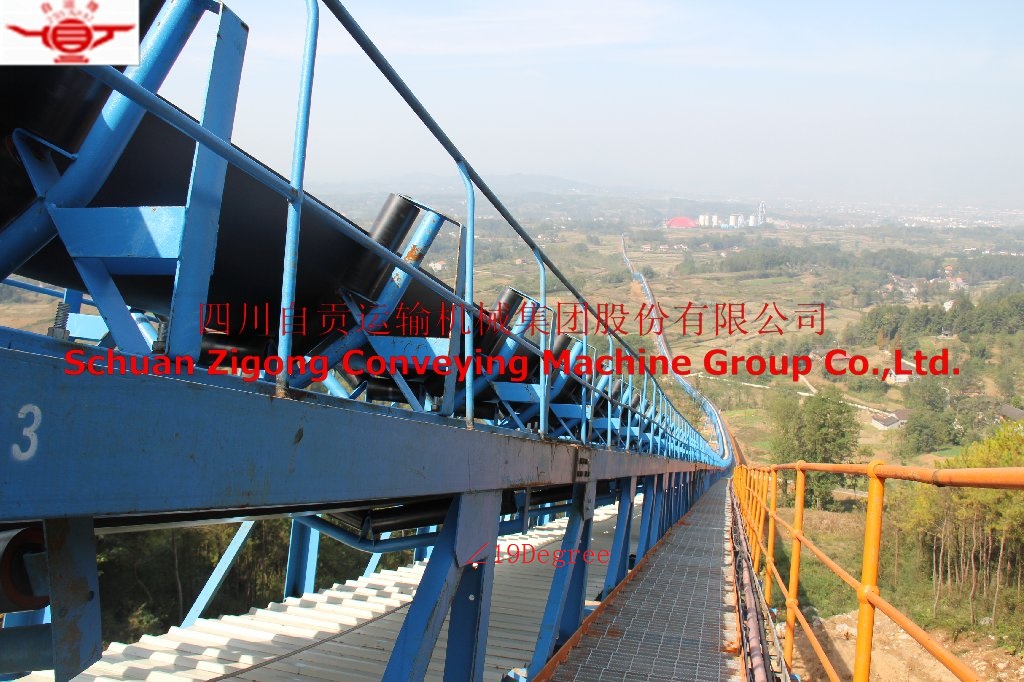

This Project Was Already Succesful.

This Project including two belt conveyors. One is pipe belt conveyor. Another is deep trough belt conveyor.

Zigong Conveying Machine Group Co.,Ltd.

No.1 Dayandong Ziliujing Ditrict Zigong Sichuan Province China

643000

e-mail long650101@163.com

Attachments

pc1-pipe conveyor_1_1_8467 model (1) (PDF)

■

Running Pictures

Running pictures

Zigong Conveying Machine Group Co.,Ltd.

No.1 Dayandong Ziliujing Ditrict Zigong Sichuan Province China

643000

e-mail long650101@163.com

Attachments

■

High-Angle Limestone Pipe Conveyor Project

Mr. Xinrong Gong,

Having reviewed the pdf of the conveyor profile I can offer the following:

- As I offered previously, the profile angles are too high for any pipe conveyor or open troughed conveyor even if it is a deep trough. At low conveying rates and on material loading the material will slide downhill. At stopping the material will surely slide down even with a full load.

- The drawing clearly shows a profile that attempts to minimize the conveying angles and in doing so incurs much elevated structure that will make the system very costly.

- A DSI GPS High angle conveyor system can handle the required slopes easily.

- Because the profile dimensions are quite large, a single flight DSI GPS will likely require steel cord belts. This will require large curve radii which will limit the systems ability the hug the natural profile but it will have better conformance than any pipe or deep troughed conveyor.

- If two or three DSI GPS flights are used for this profile, fabric belts can be used. This will allow close conformance to the profile which will result in great savings in the structural requirements.

Joe Dos Santos ■

Pipe Conveyor Slope Limit For Reference Project

Having reviewed the pdf of the conveyor profile I can offer the following:

- As I offered previously, the profile angles are too high for any pipe conveyor or open troughed conveyor even if it is a deep trough. At low conveying rates and on material loading the material will slide downhill. At stopping the material will surely slide down even with a full load.

- The drawing clearly shows a profile that attempts to minimize the conveying angles and in doing so incurs much elevated structure that will make the system very costly.

- A DSI GPS High angle conveyor system can handle the required slopes easily.

- Because the profile dimensions are quite large, a single flight DSI GPS will likely require steel cord belts. This will require large curve radii which will limit the systems ability the hug the natural profile but it will have better conformance than any pipe or deep troughed conveyor.

- If two or three DSI GPS flights are used for this profile, fabric belts can be used. This will allow close conformance to the profile which will result in great savings in the structural requirements.

Joe Dos Santos

=======================================

Joe,

Zigong says they have built and commissioned the given conveyor per the PDF file. They show many photos of the installation. PDF file shows a max. slope of 24 deg., which is well within pipe conveyor capability. They are now bragging about its success from 2013 to now. ■

High-Angle Limestone Pipe Conveyor Project

Larry,

My congratulations to Mr. Zigong for successfully defying gravity and possibly some other laws of physics. I have said many times before on this forum and in other discussions. The natural wedging of a deep trough as well as a 60% filling of a pipe section will naturally accomplish a higher conveying angle that more closely approaches the bulk material's natural angle of repose. That same wedging naturally increases the travel resistances and drives up the power draw. The problem; what happens at the lower conveying rates or when the conveyor is not loaded from end to end? You get material movement, slide back.

Remember the Hu-Rise, the Beltevator, the Zipper Belt, the Retainer belt, all supposedly successful. Where are they now. Let's revisit this thread in a couple of years.

Joe Dos Santos ■

High-angle Limestone Pipe Conveyor Project

High-angle downhill 4.2km pipe conveyor in China

Dear all,

We'll make a conveyed limestone project in China, but have a little trouble in the project,because part area of conveyor line site's downhill angle over 31 degree, so i hope we can find a partner of enough experience for solved this question, if you have any doubts or intersted in this project, please don't hesitate to contact me.

Part A: material basic data

Bulk material: limestone;

Capacity: 600 t/h;

Particle size: less than 70mm;

Density: 1.2 to 1.6 t/m3

Part B: please see attach is the project preliminary layout.

Your response will be highly appreciated.

Ruta

Emai: ruta.zhu@gmail.com

skype: ruta.zhu@gmail.com

Attachments

kaituo pj preliminary layout rev.a (PDF)

■