Benefits include: 1) Custom designed Pellet Mill control software application to meet your exact automation and system requirements, 2) Integrated mill monitoring and histogram displays, 3) Control functions maximize throughput and high output, 4) Pellet Mill is optimized based on mill condition, 5) Mill plug conditions are averted through use of smart control, and 6) Mill shutdown is automatic if it becomes

plugged.

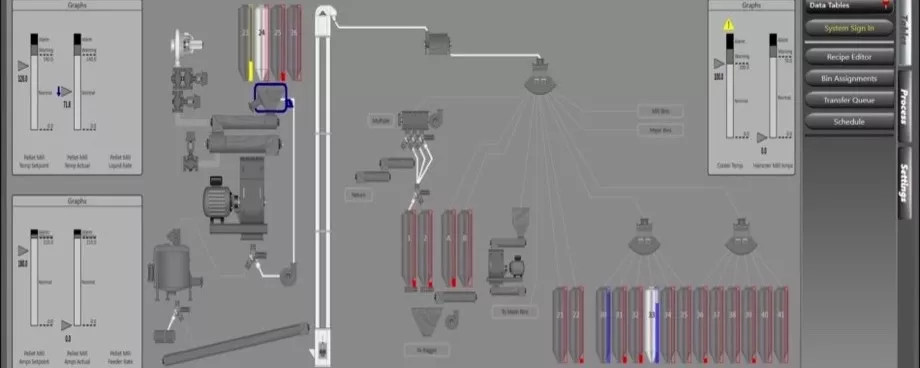

The Sterling Systems pellet mill control and feed mill automation design provides equipment and software using Allen-Bradley PLC’s and desktop PC’s running Sterling Systems’ customized Windows-based Automation Software. While the pelleting process control has historically been done manually or semi-automatically, the Sterling Systems pelleting system uses the customer production requirements and formulas to create a customized and fully-automated pelleting process.

The Sterling Systems pellet mill control and feed mill automation application is constantly evaluating information from the process. Feeder adjustments are made for dry and liquid materials to bring the pellet mill electrical current to target levels. Feeder speed ramps up, steam valve is also ramped up. The feeder and steam adjustments continue until the current and mash temperature set-points are reached. This provides for smoother and faster achievement of maximum efficiency with minimum downtime.

The custom design of the software ensures the pellet mill automation application is just what you need and want, ensuring optimum operation, maximizing throughput and mill output. The pellet mill application monitors key mill operation and functions and ensures dependability and maximizes up time.

■