Rembe And Kersting

REMBE and Kersting

Jochen Eberheim, MD of Kersting Gmbh (left)

Jochen Eberheim, Managing Director,

Kersting Gmbh Sampling + Grounding

(Photo by Schuettgut-Magazin)

SAFETY is for life.

It is their several million hours of engineering experience that makes REMBE truly exceptional. As architects of industrial safety and measurement technology, covering bursting discs, explosion protection and measurement technology, REMBE engineers invent new and appropriate solutions for any task, every single day. The manufacturer located in Brilon, Germany creates and produces customized unique pieces as well as large-lot productions with the utmost accuracy. REMBE fulfills and maintains the exact high requirements of function, safety and sustainability at all times, for every single customer.

More information on REMBErembe gmbh safety control 10691.htm

More information on Kersting12263 kersting gmbh sampling grounding.htm

Google Search - Websearch?q=rembe+site:bulk online.com

Google Search - Imagessearch?q=rembe+site:bulk online.com&client=safari&rls=en&source=lnms&tbm=isch

Interesting REMBE Videos:

International PBS 2014: Explosion by REMBEinternational pbs 2014 explosion by rembe.html

REMBE® Q-ROHR® : THE ORIGINAL OF FLAMELESS VENTINGrembe q rohr the original of flameless venting.html

REMBE on the Portalsearch?q=REMBE

REMBE is a bulk-online Leaderbulk online leaders ■

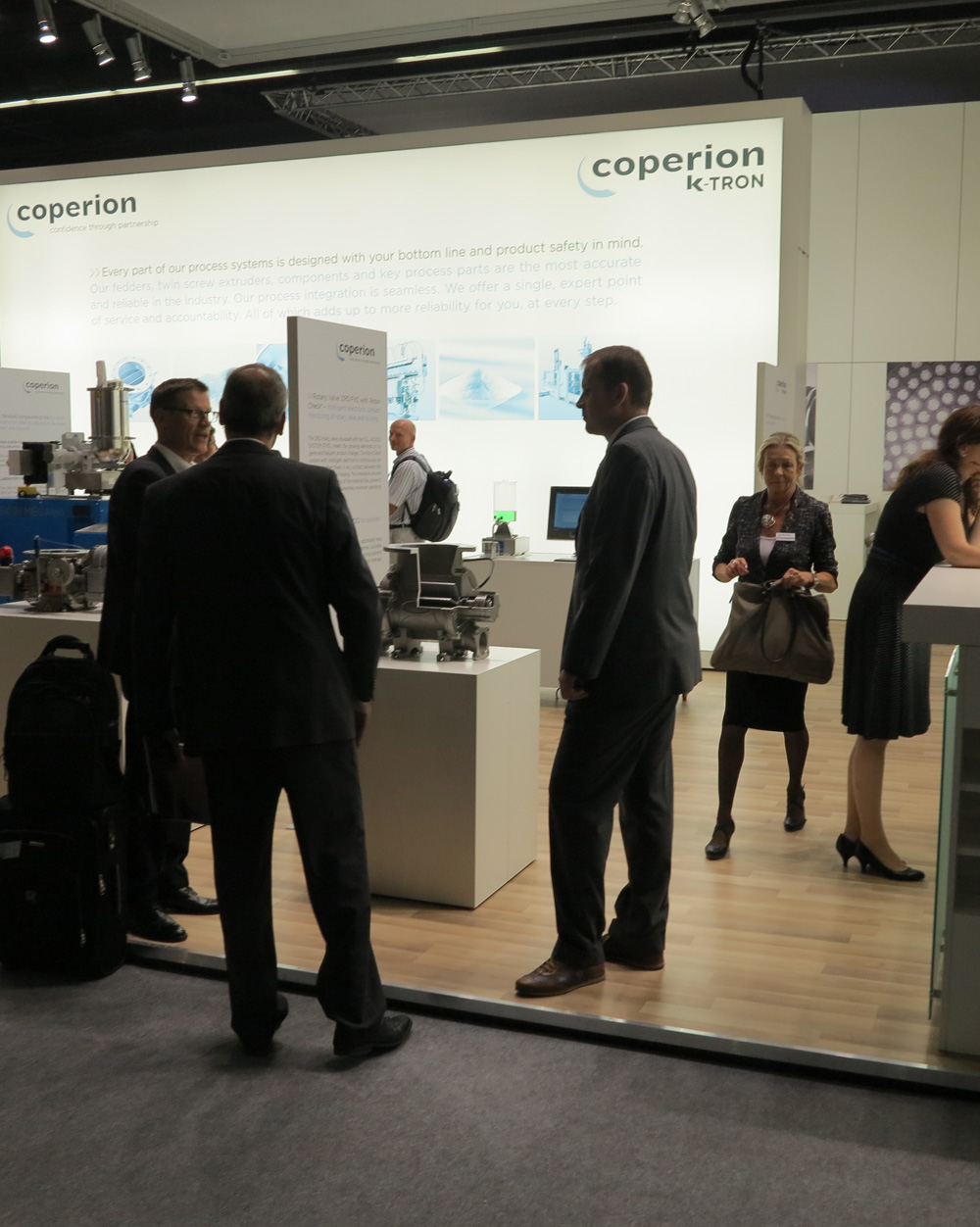

Coperion And Coperion K-Tron

Regula Sullivan, Coperion K-Tron International Ltd. (left) ■

Coperion and Coperion K-Tron

Individual solutions in processing technology and bulk material handlingshowthread.php?28370

Coperion K-Tron is a global leader in the design, installation and maintenance of process feeders and pneumatic conveying systems for the handling of bulk solids.

Coperion K-Tron is an industry expert in designing systems to convey hard to handle materials. Specialized in high accuracy feeding and metering of powders and bulk materials, K-Tron develops, manufactures and oversees every aspect of its equipment, thus ensuring the greatest accuracy, consistency and long-term value. K-Tron holds numerous patents for weighing, mechanical and control technologies and their application to bulk solids handling.

More information on Coperion K-Troncoperion k tron 201995.htm

More information on Coperion2408 coperion.htm

Google Search - Websearch?q=coperion+k tron+muhr+site:bulk online.com

Google Search - Imagessearch?q=coperion+k tron+muhr+site:bulk online.com&source=lnms&tbm=isch

Coperion on the Portalsearch?q=coperion+%2B+coperion+k tron

Coperion K-Tron is a "bulk-online Leader"bulk online leaders

Ute Wöhlbier, Powder/Bulk Portal (center)

Monika Hanser, Coperion (right)

Vortex Valves

Vortex Valves

Lawrence Millington,

European Sales Manager,

VORTEX U.K.

For over 35 years, Vortex has provided material handling solutions to a global network of Original Equipment Manufacturers, Fortune 500 companies, and process engineering firms. Throughout the world, over 10,000 companies such as PolyOne, Dow Chemical, Nestle, and Morton Salt have utilized our innovative slide gates, diverters, iris valves, and custom engineered products to improve process efficiency.

Because the characteristics of dry bulk materials are endless, there is no such thing as an off-the-shelf solution. By listening to our customer´s needs, our engineers create the right design for the application.

The result is a custom valve that will out-perform and out-last the competition.

More information on Vortex1780 vortex.htm

Google Search - Websearch?client=safari&rls=de de&q=vortex+valves+site:bulk online.com

Google Search - Imagessearch?q=vortex+valves+site:bulk online.com&hl=de&newwindow=1&safe=active&client=safari&rls=en&prmd=ivns&source=lnms&tbm=isch

Corporate Profileshowthread.php?13099 Salina Vortex Corporation

Watch this Vortex Valves videoVortex Slide Gates Diverter Valves Loading Spout

Equipment Focus:

• Vortex® Valves Slide Gatesshowthread.php?21526 vortex valves slide gates

• Vortex® Valves Line Divertersshowthread.php?21527 vortex valves line diverters

• Vortex® Gravity Flow Slide Gatesshowthread.php?21535 vortex gravity flow slide gates

• Vortex® Gravity Flow Divertersshowthread.php?21536 vortex gravity flow diverters

• Vortex® Iris Valvesshowthread.php?21537 vortex iris valves

• Vortex® Butterfly Valvesshowthread.php?21538 vortex butterfly valves

Trademarks / Brandnames:

Vortex Valves

Vortex Valves Europe, Ltd.

Vortex Quantum Series Orifice Gate

Vortex HDP Slide Gate

Vortex Maintenance Gate

Vortex Roller Gate

Vortex Dual Cylinder Roller gate

Vortex Quick Clean Orifice Gate

Vortex Hand Slide Orifice Gate

Vortex Aggregate Gate

Vortex Wye Line Diverter

Vortex Flex Tube Diverter

Vortex Fill Pass Diverter

Vortex Multi-port Diverter

Vortex Seal Tite Diverter

Vortex Aggregate Diverter

Vortex Iris Valve

Vortex Valves on the Portalsearch?q=vortex

Vortex Valves is a "bulk-online Leader"bulk online leaders ■

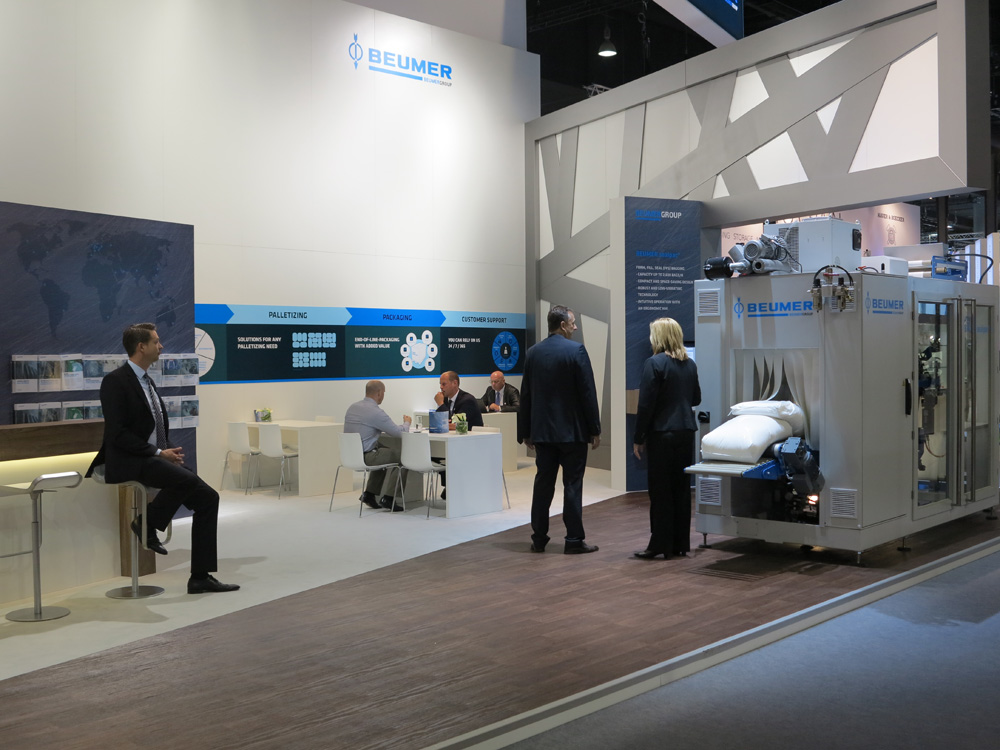

Beumer Group

BEUMER Group

Verena Breuer (left) and Ute Wöhlbier

■

BEUMER Group is an international manufacturing leader in intralogistics in the fields of conveying, loading, palletizing, packaging, sortation and distribution technology. Together with Crisplant a/s and Enexco Teknologies India Limited, the BEUMER Group employed some 4,000 people in 2014. The group generated an annual turnover of approximately 680 million euros. With its subsidiaries and sales agencies, BEUMER Group is present in many industries worldwide.

More information on BEUMER Group2290 beumer group.htm

Google Search - Websearch?client=safari&rls=en&q=beumer+site:bulk online.com

Google Search - Imagessearch?q=beumer+site:bulk online.com&hl=en&client=safari&rls=en&prmd=imvns&source=lnms&tbm=isch

Video: BEUMER Belt Conveyor 12.5 km in Sichuan, Chinabeumer belt conveyor 12 5 km in sichuan china.html

BEUMER on the Portalsearch?q=beumer

BEUMER Group is a "bulk-online Leader"bulk online leaders

Flsmidth

FLSmidth

FLSmidth-Pneumatic Transport is a worldwide leader in pneumatic bulk conveying for the process and materials handling industries. We offer innovative technology and broad experience in all aspects of material handling systems.

Since our founding as Fuller Company in 1926, our pneumatic conveying systems have moved millions of tons of dry bulk solids in numerous applications. Modern, efficient technology and proven equipment are only two of our strengths.

We excel at system design, engineering and supply of complete bulk material transfer systems.

More information on FLSmidth2285 flsmidth.htm

Google Search - Websearch?client=safari&rls=de de&q=FLSmidth+site:bulk online.com

Google Search - Imagessearch?q=FLSmidth+site:bulk online.com&client=safari&rls=de de&source=lnms&tbm=isch

FLSmidth on the Portalsearch?q=FLSmidth

Trademarks / Brandnames:

Airslide™ Gravity Conveying Systems

Ful-Vane™ Compressors

Fuller-Kinyon™ Pumps

Kompact™ Pumps

MODU-DENSE™ Dense Phase Conveying Systems

Pneu-Boost™ Conveying Boosters

SK Diverter Valves

FLSmidth is a "bulk-online Leader"bulk online leaders and a "bulk-online Sponsor"sponsors. ■

Brabender Technologie

Brabender Technologie

Klaus Donsbach,

Mgr. Marketing, Brabender Technologie

Brabender Technologie1246 brabender technologie.htm is a leading supplier of machinery and systems for bulk ingredient feeding, weighing, discharging and flow metering with a world-wide consulting, sales and service network.

• Gravimetric metering feeders

• Volumetric metering feeders

• Weigh-batching systems

• Discharge aids

• Flow meters

More information on Brabender Technologie1246 brabender technologie.htm

Google Search - Websearch?client=safari&rls=de de&q=brabender+site:bulk online.com

Google Search - Imagessearch?q=Brabender+site:bulk online.com&hl=en&client=safari&rls=en&prmd=imvns&source=lnms&tbm=isch

Equipment Focus / Bulk Bag Unloadersshowthread.php?21598 brabender bulk bag unloaders

Corporate Profileshowthread.php?t=15178

Brabender Technologie is a "bulk-online Leader"bulk online leaders ■

Geroldinger

Geroldinger

Johannes Scherleitner (right)

Sales Manager

Ing. Walter Geroldinger, Managing Director

Tamara Tischler, Sales

(Photo by Schuettgut-Magazin)

Geroldinger engineers and manufactures tailored solutions to move bulk solids reliably and precisely to various processes.

The materials handling specialists are leading global providers of technology for a wide range of complex applications. On the basis of Geroldingers experience with hundreds of plants and facilities the company developed a unique product for producers and processors of bulk materials - the Bulk Solids Logistics Plant. A one stop plant that buffers and conveys bulk solids in exact quantities at the right speed to wherever they need to go. Geroldingers Bulk Solids Logistics Plant proof outstanding operational reliability and a customized operator interface.

Patented components like the OSZILLOMAT discharge and dosing aid especially developed for demanding bulk solids or the MULTIGON – an octagonal silo - allowing exceptional applications.

More information on Geroldinger2589 geroldinger.htm

Google Search - Websearch?client=safari&rls=de de&q=GEROLDINGER+site:bulk online.com

Google Search - Imagessearch?q=GEROLDINGER+site:bulk online.com&safe=active&client=safari&rls=de de&source=lnms&tbm=isch

Watch this Geroldinger Videogeroldinger oszillomat the effective and efficient discharging system.html

GEROLDINGER on the Portalsearch?q=geroldinger

Geroldinger is a "bulk-online Leader"bulk online leaders ■

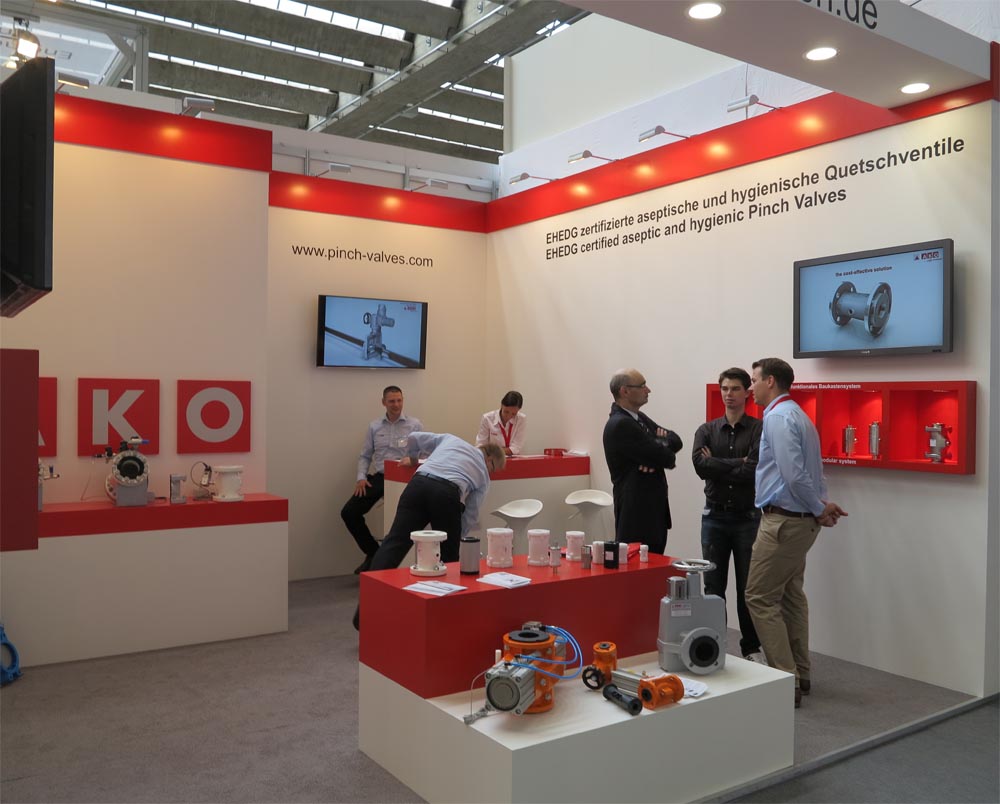

Ako Pinch Valves

AKO Pinch Valves

Christina Martin-Sanchez,

Manager Marketing, AKO Armaturen

AKO Armaturen & Separationstechnik GmbH is the European market leader for air operated Pinch Valves. AKO is a family-run company, which has been manufacturing reliable, cost-effective and innovative Pinch Valves for 28 years.

In addition, AKO’s product portfolio includes a wide range of different mechanical pinch valve series, knife gate valves, pipe manometer, pressure relief valves, sleeves for pinch valves and pinch valve or knife gate valve accessories.

More information on AKO2154 ako armaturen separationstechnik.htm

Google Search - Websearch?client=safari&rls=en&q=AKO+Armaturen+%26+Separation+site:bulk online.com

Google Search - Imagessearch?q=AKO+Armaturen+%26+Separation+site:bulk online.com&client=safari&rls=en&source=lnms&tbm=isch

AKO on the Portalsearch?q=ako+ ■

Berthold Technologies

Berthold Technologies

Diana Keppler (center)

Marketing

Berthold Technologies has been involved in process measurement technology since 1949. We are an internationally active company with over 300 employees. The quality management system is certified according to DIN EN ISO 9001:2008, ISO 14001:2004, BS OHSAS 18001:2007 and KTA 1401.

Berthold Technologies´ Process Control Division offers solutions for the non-contacting measurement of level, density, concentration, bulk flow and moisture. As the global leader in radiometric technology our products are characterized by an outstanding measurement performance and reliability.

More information on Berthold Technologies2287 berthold technologies.htm

Google Search - Websearch?client=safari&rls=en&q=berthold+site:bulk online.com

Google Search - Imagessearch?q=berthold+site:bulk online.com&hl=en&client=safari&rls=en&prmd=imvns&source=lnms&tbm=isch

Berthold Technologies on the Portalsearch?q=berthold ■

Dmn-Westinghouse

DMN-Westinghouse

Tonneke Krempel,

Manager Marketing Services & PR

DMN-WESTINGHOUSE designs and manufactures a complete range of rotary valves, diverter valves and other related components for the bulk solids handling industry. Offering tailor made solutions for chemical, food, plastics and pharmaceutical industries.

Main products are airlocks, blowing seals, diverters ( plug, tube, multi-port, flap, ball ), slide gate valves, discharge units, pipe couplings, pressure relief valves. The components are available in a variety of materials, such as stainless steel, cast iron, aluminium. USDA approved and explosion-proof models are available.

More information about DMN-Westinghouse1802 dmn westinghouse.htm

Google Search - Websearch?client=safari&rls=de de&q=DMN WESTINGHOUSE+site:bulk online.com

Google Search - Imagessearch?q=DMN WESTINGHOUSE+site:bulk online.com&client=safari&rls=de de&source=lnms&tbm=isch

DMN-Westinghouse on the Portalsearch?q=dmn westinghouse ■

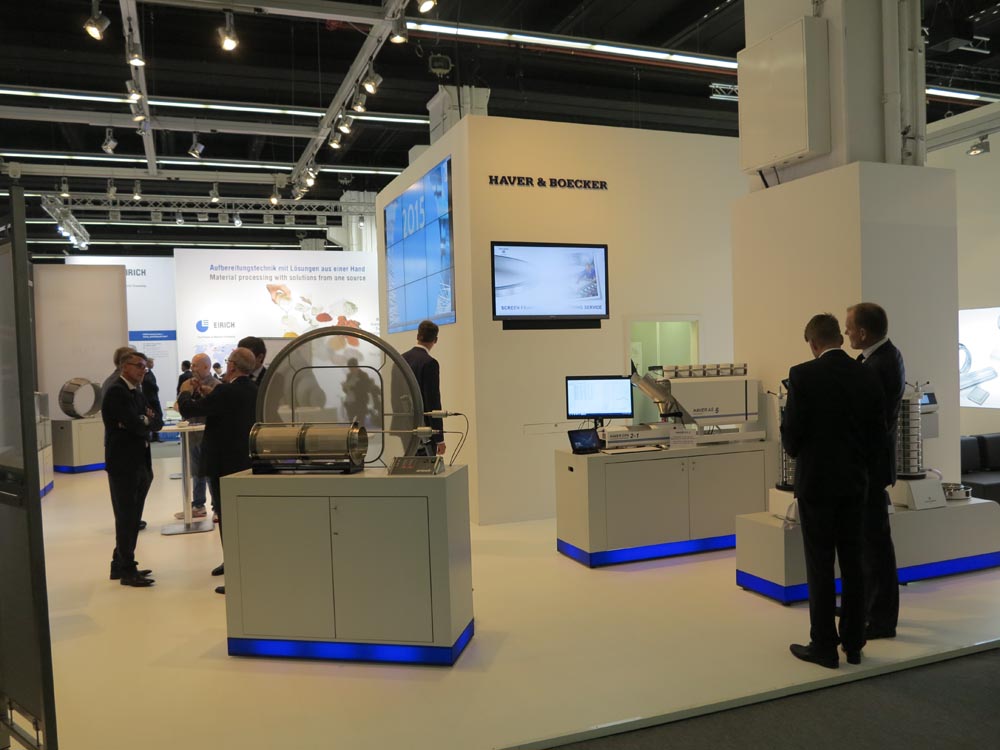

Haver & Boecker Maschinenfabrik

HAVER & BOECKER Maschinenfabrik

The HAVER & BOCKER Machinery Division has its headquarters in Oelde, Germany and is, in addition to the Wire Weaving Division, one of the two divisions of the HAVER & BOECKER OHG. The Machinery Division and its various subsidiary companies are specialised in developing and marketing systems and plants for filling and handling loose bulk products. Belonging to the product line are packing and loading systems for powder-type and granulated products such as cement, dry mortar or granulates, screening machines for classifying gravel, crushed stone, sand, and ore, and packing machines for filling food and feed products. The product range also includes filling stations and entire filling lines for liquid and pasty products, stirring systems and mixers, palletizing and loading systems, ship loading and unloading systems.

More information about HAVER & BOECKER2063 haver boecker maschinenfabrik.htm

Google Search - Websearch?client=safari&rls=de de&q=Haver++site:bulk online.com

Google Search - Imagessearch?q=Haver++site:bulk online.com&client=safari&rls=de de&source=lnms&tbm=isch

HAVER & BOECKER on the Portalsearch?q=Haver+%26+Boecker+ ■

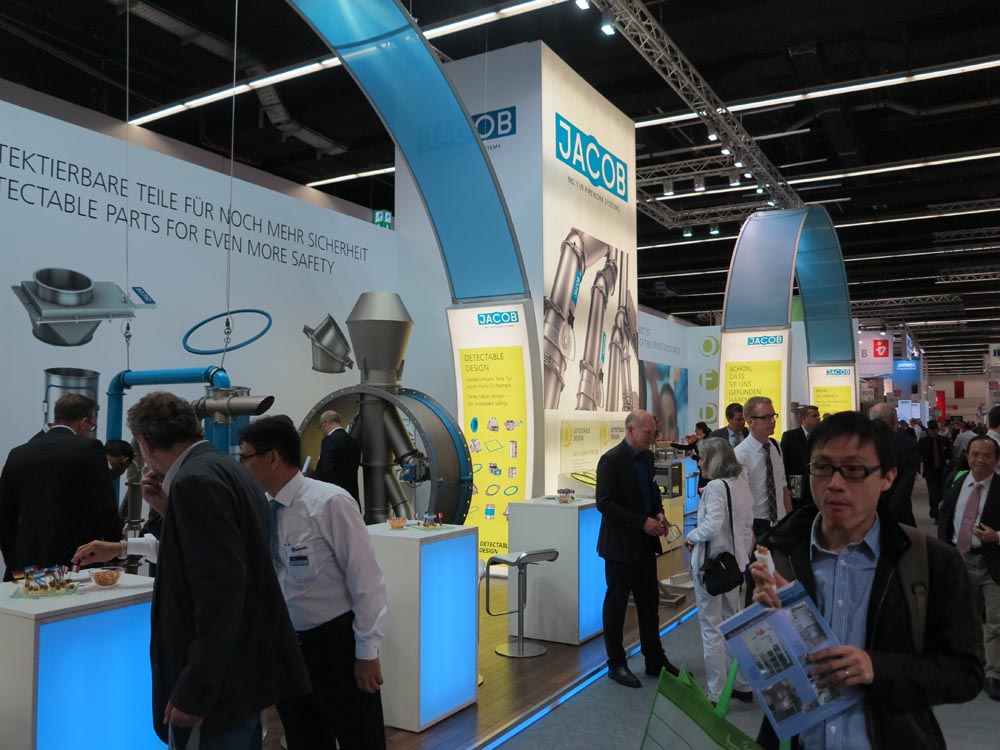

Fr. Jacob Soehne

Fr. Jacob Soehne

JACOB is No. 1 in modular tubing systems in Europe with a worldwide presence.

Conveying tubing systems for bulk goods handling, dust extraction and ventilation plants for environmental techniques are the large scopes for JACOB shock explosion proof tubing systems. 60-800 mm diameter, powder-coated, galvanized and stainless steel.

More information on Jacob2125 fr jacob söhne.htm

Google Search - Websearch?num=100&hl=en&client=safari&rls=en&q=Fr.+Jacob+Soehne+site%3Abulk online.com

Google Search - Imagessearch?q=Fr.+Jacob+Soehne+site:bulk online.com&client=safari&hl=en&rls=en&source=lnms&tbm=isch

DETECTABLE DESIGN series now exclusive in the series-manufactured rangeshowthread.php?28508 JACOB ROHRSYSTEME auf der ACHEMA 2015 DETECTABLE DESIGN series&p=86412#post86412

Jacob on the Portalsearch?q=jacob+s%C3%B6hne

Watch this JACOB Video: Modular Pipework Systemsjacob modular pipework systems.html ■

Russell Finex

Russell Finex

More information on Russell Finex8633 russell finex.htm

Google Search - Websearch?client=safari&rls=en&q=Russell+Finex+site:bulk online.com&gwsrd=ssl

Google Search - Imagessearch?q=Russell+Finex+site:bulk online.com&client=safari&rls=en&source=lnms&tbm=isch

Russell Finex on the Portalsearch?q=Russell+Finex ■

Alexanderwerk Ag

Alexanderwerk AG

More information on Alexanderwerk9503 alexanderwerk.htm

Google Search - Websearch?q=Alexanderwerk+site:bulk online.com

Google Search - Imagessearch?q=Alexanderwerk+site:bulk online.com&source=lnms&tbm=isch

Alexanderwerk on the Portalsearch?q=Alexanderwerk ■

Ava-Huep

AVA-Huep GmbH u. Co. KG

More information on AVA-Huep2294 ava huep.htm

Google Search - Websearch?hl=de&client=safari&rls=de de&q=ava huep+site%3Abulk online.com

Google Search - Imagessearch?q=ava huep+site:bulk online.com&client=safari&hl=de&rls=de de&source=lnms&tbm=isch

AVA-Huep on the Portalsearch?q=AVA huep

Watch this AVA-Huep Videoava in motion at powtech 2013.html ■

Concetti Group

Concetti Group

More information on Concetti9280 concetti group.htm

Google Search Websearch?client=safari&rls=en&q=concetti+site:bulk online.com

Google Search - Imagessearch?q=concetti+site:bulk online.com&safe=active&client=safari&rls=en&source=lnms&tbm=isch

Concetti on the Portalsearch?q=concetti ■

Dec Group

Dec-Group

More information on Dec Group8695 dec deutschland.htm

Google Search - Websearch?q=Dec+Group+site:bulk online.com

Google Search - Imagessearch?q=Dec+Group+site:bulk online.com&source=lnms&tbm=isch

Dec Group on the Portalsearch?q=dec+group ■

Dinnissen Process Technology

Dinnissen Process Technology

More information on Dinnissen8158 dinnissen.htm

Google Search - Websearch?client=safari&rls=en&q=dinnissen+site:bulk online.com

Google Search - Imagessearch?q=dinnissen+site:bulk online.com&hl=de&safe=active&client=safari&rls=en&prmd=imvns&source=lnms&tbm=isch

Dinnissen on the Portalsearch?q=dinnissen ■

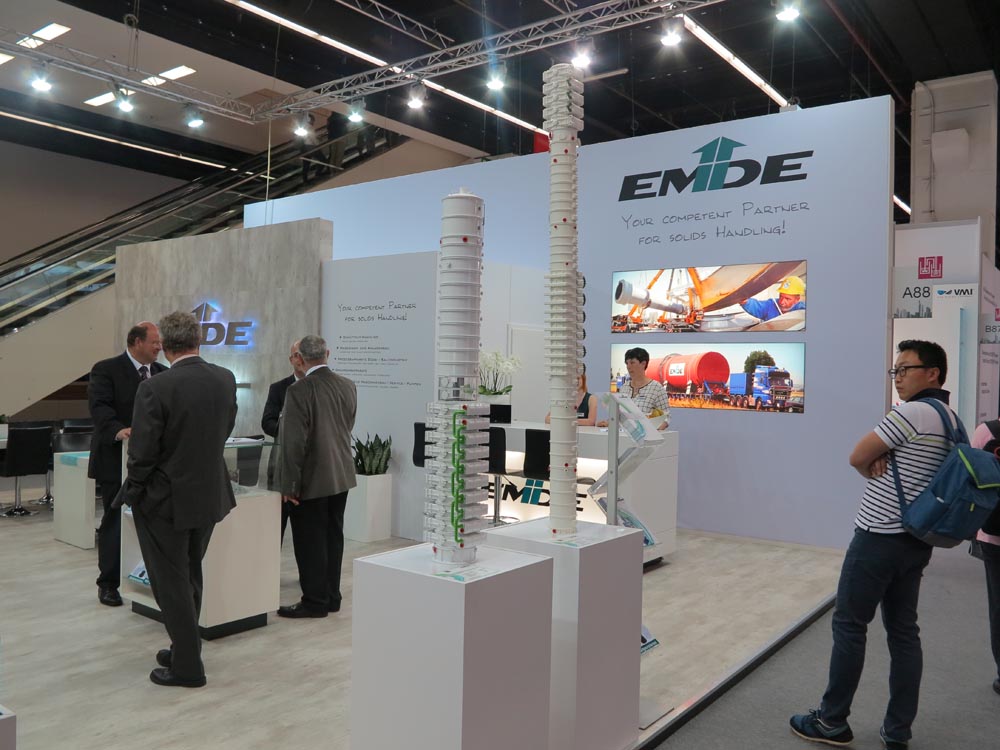

Emde Industrie-Technik

Emde Industrie-Technik GmbH

More information on EMDE8942 emde industrie technik.htm

Google Search – Websearch?q=emde+site:bulk online.com"

Google Search – Imagessearch?q=Emde+site:bulk online.com&client=safari&rls=en&source=lnms&tbm=isch

EMDE on the Portalsearch?q=emde ■

Endress+Hauser Meßtechnik

Endress+Hauser Meßtechnik GmbH+Co. KG

More information on Endress+Hauser9122 endress hauser messtechnik.htm

Google Search – Websearch?q=endress+hauser+site:bulk online.com

Google Search – Imagessearch?q=endress%2Bhauser+site:bulk online.com&client=safari&rls=en&biw=1159&bih=1194&source=lnms&tbm=isch

Endress+Hauser on the Portalsearch?q=endress%2Bhauser ■

Kreisel

KREISEL GmbH & Co. KG

Enrico Kasper (left)

Director Sales

Carsten Mevius

Head of Sales, Bulk Material Handling

More information on KREISEL2238 kreisel.htm

Google Search - Websearch?q=Kreisel+site%3Abulk online.com

Google Search - Imagessearch?q=Kreisel+site:bulk online.com&client=firefox a&rls=org.mozilla:de:official&channel=fflb&source=lnms&tbm=isch

KREISEL on the Portalsearch?q=kreisel

Schäffer on the Portalsearch?q=sch%C3%A4ffer ■

Lindor

Lindor Machinefabrieken B.V.

For more information on Lindor8169 lindor machinefabrieken.htm

Google Search - Websearch?client=safari&rls=en&q=Lindor+site:bulk online.com

Google Search - Imagessearch?q=Lindor+site:bulk online.com&client=safari&rls=en&source=lnms&tbm=isch

Lindor on the Portalsearch?q=lindor ■

Lödige

Gebrüder Lödige Maschinenbau GmbH

More information on Lödige8767 gebr lödige maschinenbau.htm

Google Search - Websearch?client=safari&rls=en&q=lodige+site:bulk online.com

Google Search - Imagessearch?q=lodige+site:bulk online.com&safe=active&client=safari&rls=en&source=lnms&tbm=isch

Watch this Loedige Videogebruder lodige leader in industrial processing.html

Lödige on the Portalsearch?q=loedige ■

Matcon

MATCON

Discover the latest thinking on LEAN handling of powders, granules and tablets at ACHEMA 2015showthread.php?28396 Matcon LEAN Handling of Powders Granules and Tablets at ACHEMA 2015

More information on Matcon Ltd.9559 matcon.htm

Google Search - Websearch?client=safari&rls=en&q=matcon+site:bulk online.com

Google Search - Imagessearch?q=matcon+site:bulk online.com&client=safari&rls=en&source=lnms&tbm=isch

Matcon on the Portalsearch?q=matcon ■

Nettervibration

Netter Vibrationstechnik GmbH

More information on NetterVibration2118 nettervibration.htm

Google Search - Websearch?num=100&hl=de&client=safari&rls=en&q=netter+site%3Abulk online.com

Google Search - Imagessearch?q=netter+site:bulk online.com&client=safari&hl=de&rls=en&source=lnms&tbm=isch

NetterVibration on the Portalsearch?q=nettervibration ■

Piab

PIAB AB

More information on PIAB8761 piab.htm

Google Search - Websearch?client=safari&rls=en&q=Piab+site:bulk online.com

Google Search - Imagessearch?q=Piab+site:bulk online.com&safe=active&client=safari&rls=en&source=lnms&tbm=isch

PIAB on the Portalsearch?q=piab ■

Schrage Rohrkettensystem Gmbh

Schrage Conveying Systems

Frank Schrage (left) and Walter Schulz

More information on Schrage Rohrkettensystem10187 schrage rohrkettensystem.htm

Google Search - Websearch?q=schrage+site:bulk online.com

Google Search - Imagessearch?q=schrage+site:bulk online.com&source=lnms&tbm=isch

Schrage Rohrkettensystem on the Portalsearch?q=schrage ■

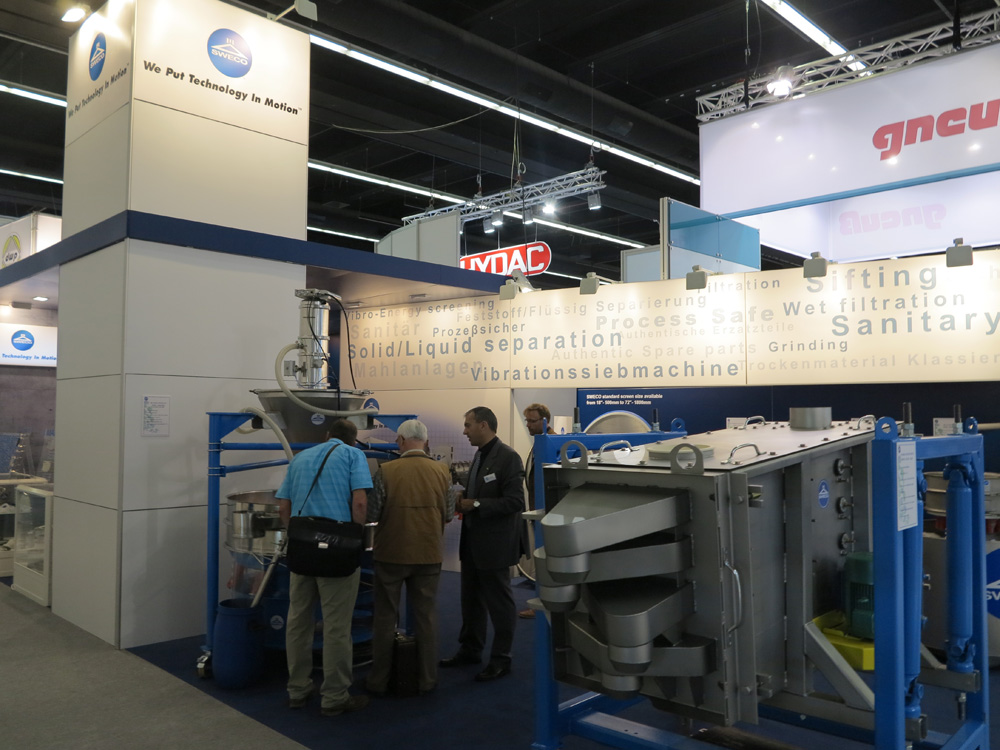

Sweco

SWECO

More information on SWECO Europesweco europe s a 2150.htm

More information on SWECO USA1610 sweco.htm

Google Search - Websearch?q=sweco+site%3Abulk online.com

Google Search - Imagessearch?q=sweco+site:bulk online.com&client=firefox a&hs=DDZ&rls=org.mozilla:de:official&channel=sb&source=lnms&tbm=isch

SWECO on the Portalsearch?q=sweco ■

Three-Tec

Three-Tec GmbH

More information on Three-Tec11192 three tec dosiergeräte systeme .htm

Google Search - Websearch?q=Three Tec+GmbH+Dosiergeräte+%26+Systeme+site%3Abulk online.com

Google Search - Imagessearch?q=Three Tec+GmbH+Dosiergeräte+%26+Systeme+site:bulk online.com&client=firefox a&hs=bf6&rls=org.mozilla:de:official&channel=sb&source=lnms&tbm=isch

Three-Tec on the Portalsearch?q=three tec ■

Vega

VEGA

More information on VEGA8116 vega grieshaber kg.htm

Google Search - Websearch?client=safari&rls=en&q=vega+site:bulk online.com

Google Search - Imagessearch?q=vega+site:bulk online.com&client=safari&rls=en&source=lnms&tbm=isch

VEGA on the Portalsearch?q=VEGA ■

Windmöller & Hölscher

Windmöller & Hölscher KG

Windmöller & Hölscher präsentiert EASY-CONTROL für FFS-Absacklinien auf der diesjährigen ACHEMAshowthread.php?28363 Windm%F6ller amp H%F6lscher pr%E4sentiert EASY CONTROL auf der ACHEMA

More information about Windmöller & Hölscher8122 windmöller hölscher.htm

Google Search - Websearch?q=Windmöller+%26+Hölscher+site:bulk online.com

Google Search - Imagessearch?q=Windmöller+%26+Hölscher+site:bulk online.com&source=lnms&tbm=isch

W & H on the Portalsearch?q=Windm%C3%B6ller+%26+H%C3%B6lscher

W & H Videowh topas sl ffs bagging machine.html ■

ACHEMA 2015 Photo Gallery

ACHEMA 2015 Ends on a High Note:

Satisfaction and beyond

The initial feedback received by the organizers of ACHEMA 2015 paints a very favorable picture: positive event statistics, a long list of announcements on business deals and a lot of work for the sales organizations in the weeks ahead to follow up on new leads. ACHEMA attracted slightly more exhibitors this year. Visitor numbers were almost exactly the same as for the previous ACHEMA show. 166,444 trade visitors from around the world made their way to the Frankfurt exhibition grounds on June 15th – 19th, 2015. 3,813 exhibitors from 56 countries put the latest innovations for the chemical, pharmaceutical and food industries on display. ACHEMA 2012 attracted 166,447 visitors and 3,773 exhibitors. The extensive range of new products and initial product introductions underline the importance of ACHEMA as the “world innovation summit”.

“It will take us a few more days to fully analyze the visitor statistics. However, the initial figures indicate that visitor length of stay has reached a turning point,” said Thomas Scheuring, CEO of DECHEMA Ausstellungs-GmbH. “Visitors came to the exhibition grounds on more than one day. They had specific interests and they took all the time they needed to gather a large volume of information.” Initial trends indicate that the proportion of international visitors has risen by a significant margin. Also for the first time, more than half of exhibitors (53.9%) came from outside Germany. China was second in the exhibitor number rankings behind Germany and was ahead of Italy by only the narrowest of margins. There was also a substantial increase in the number of companies from Turkey, Taiwan and India. Austria, the UK and Spain showed the largest increase in the EU region. France and the US were again well represented.

133,436 m of exhibition space was divided up between 11 exhibitor groups. Growth was particularly noticeable in the pharmaceutical, packaging and warehouse logistics industries, which booked additional space this year, as well as in the instrumentation and process control category. This latter group benefited from the unmistakable tendency in the process industry to further increase the level of automation as well as from user demand for greater flexibility, both of which come under the umbrella of Industry 4.0. Equipment manufacturing along with lab and analysis systems, however, showed a slight decline.

The congress program was also well received. “Our efforts to streamline the program and avoid parallel sessions dedicated to similar topics were well worth the effort," claimed DECHEMA CEO Prof. Kurt Wagemann. “That made it much easier for visitors to arrange their agendas." Despite the streamlining, the roughly 800 presentations covered the full spectrum of process technology. The sessions dedicated to the focus topics were very well attended, and material technology also attracted a large audience. An above-average number of visitors attended the sessions on heat exchangers and energy efficiency. The two panel discussions "Bioeconomy in the Shale Gas Trap?" and "German Energy Turnaround – the Future or No-Man’s Land" were genuine highlights and attracted a full house.

One issue outside the boundaries of the focus themes BiobasedWorld, industrial water management and innovative process analytical technology surfaced as a common thread in all of the discussions, namely Germany’s positioning as an innovation hub. Many industry experts have concerns. Germany and Europe are in danger of falling behind as attractive business locations unless there is genuine improvement in the innovation climate. The warning was issued by a number of high-profile industry figures at ACHEMA. At the opening press conference on Monday, VCI CEO Dr. Utz Tillmann among others expressed the need for a better innovation landscape and an "innovation culture". At a panel discussion on Tuesday, Wolfgang Büchele, who is Chairman of the Board at Linde, emphasized the need for a greater willingness to embrace change. Otherwise, innovation will happen in other parts of the world and not in Germany and Europe. In his keynote talk on Thursday, Bayer Technology Services CEO Dr. Dirk van Meirvenne urged the chemical industry to concentrate on innovation.

The next date on the event calendar for the process industry is AchemAsia which will be held in Beijing on May 9th – 12th, 2016. The next ACHEMA is scheduled to take place on June 11th – 15th 2018 in Frankfurt am Main.

ACHEMA 2015 at Frankfurt am Main, Germany

******

bulk-online Photo Gallery:

The Powder/Bulk Portal presents a few photographs of companies active in the field of powder and bulk solids handling and processing and concentrates on those which support our and your Portal financially.

Comments, corrections, suggestions, more or better photos and photo removal requests should be addressed to Dr. Reinhard Wohlbier at wohlbier@bulk-online.com

Copyright © 2015 by Online Services Dr. Wöhlbier ■