Re: Belt Sag And Belt Life

Dear Mr.nimra7891,

Could you please post the general arrangement drawing, related to the problem mentioned by you?

Regards, ■

Sublime Juncture.

Think about it: if you can't insert idlers should you be thinking about a belt conveyor? Your problem has nothing to do with conveying until you get your plant layout sorted out. ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Re: Belt Sag And Belt Life

Are you saying you can't even install a truss or anything to support the idlers? I have even supported that size of conveyor with 6 meter channels with no problems.

Hope you have lots of money in the budget for spillage cleanup in the unsupported area. ■

Gary Blenkhorn

President - Bulk Handlng Technology Inc.

Email: garyblenkhorn@gmail.com

Linkedin Profile: http://www.linkedin.com/in/gary-blenkhorn-6286954b

Offering Conveyor Design Services, Conveyor Transfer Design Services and SolidWorks Design Services for equipment layouts.

4% Belt Sag

=================================================================

Prolonged operation at 4% belt sag will damage the belt internals due to the high belt wing-to-center roll junction strain. SO, yes it will shorten belt life. Rubber does fatigue.

You may inherit a 3 for1 belt assembly.

Very sad when engineers post extremely poor judgment in design. You will not find 3-4% level of sag recommended in any design guide. Most often, the number will be 1% or less in one local position.

Just gives the client distrust in engineers. At 4% sag, the belt trough becomes distorted and may lead to spillage. Power will go up, et. al. as you note. ■

Re: Belt Sag And Belt Life

Hi mr. Ganesh,

unfortunately I can't share the arrangement drawing. it is a work in progress and what I mentioned was one of the proposed solutions.

regards ■

Drawings Are ....

...still...the language of engineering.

We can only surmise that there is something to hide and because we don't/can't work blind the matter seems destined to oblivion. ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Not Possible Is Impossible!!

Dear John,

Thanks for your reply. it shows you really care about every aspects of the engineering. Glad to know that.

As I said in my previous reply, that was one of the proposed solutions. we are trying to sort out the layout, but it is not always possible to use simple old solutions.

I am wondering why you think of the problem as NOT possible. I have seen several stacker conveyors where the belt is not supported for few meters. I assume that is not a big deal! (or maybe it is!) probably it is not a good idea to repeat what we see, unless we are sure about the consequences. that is what I intended! knowing the concept (or simply probable problems) and then deciding! would your reply be the same if I write 2 percent sag for 3 meters of unsupported length?

Regards, ■

Re: Belt Sag And Belt Life

Dear Gary,

Thank you for your reply.

truss was among the solutions and was ruled out, instead a cable supported idlers was proposed which is under investigation.

would you mind telling me more about the spillage in the unsupported area. just out of curiosity I check formulas for slippage, spillage and material lift off, and everything seems OK (although the belt tension is a little high, but safety factor is not less than 10). I know everything is not in the formulas/standards/manuals and experience has a lot to play. I hoped someone would share.

Regards, ■

Re: Belt Sag And Belt Life

href="showthread.php?p=87624#post87624" rel="nofollow">

Thank you for your reply.

truss was among the solutions and was ruled out, instead a cable supported idlers was proposed which is under investigation.

would you mind telling me more about the spillage in the unsupported area. just out of curiosity I check formulas for slippage, spillage and material lift off, and everything seems OK (although the belt tension is a little high, but safety factor is not less than 10). I know everything is not in the formulas/standards/manuals and experience has a lot to play. I hoped someone would share.

Regards,

You do not mention the belt speed so it is hard to say what the % fill will be on the cross section of the belt. If you were to go over 70% fill I would think you would have spillage issues. Here is a typical sketch of a 48" conveyor at 2,500 TPH supported around 27' on a channel stringer.

Attachments

■

Gary Blenkhorn

President - Bulk Handlng Technology Inc.

Email: garyblenkhorn@gmail.com

Linkedin Profile: http://www.linkedin.com/in/gary-blenkhorn-6286954b

Offering Conveyor Design Services, Conveyor Transfer Design Services and SolidWorks Design Services for equipment layouts.

Re: Belt Sag And Belt Life

Prolonged operation at 4% belt sag will damage the belt internals due to the high belt wing-to-center roll junction strain. SO, yes it will shorten belt life. Rubber does fatigue.

You may inherit a 3 for1 belt assembly.

Very sad when engineers post extremely poor judgment in design. You will not find 3-4% level of sag recommended in any design guide. Most often, the number will be 1% or less in one local position.

Just gives the client distrust in engineers. At 4% sag, the belt trough becomes distorted and may lead to spillage. Power will go up, et. al. as you note.

Dear Mr. nordel,

Glad you find this thread worthy of replying and really thanks that at least you answered some part of my question.

".... will damage the belt internals due to the high belt wing-to-center roll junction strain": I see that the belt sag is like a concave curve, and there is a difference between tensions in edge, neutral plane and the center. what I don't understand is, What is the difference between a curve and this situation! you are right about the high strain, but it seems similar to the case in convex curve, probably that is even extremer with steel cord belts, where controlled edge buckling is allowed (CEMA6).

you are right, rubber does fatigue. one question would be: is one point in a conveyor >500 meters C2C this important in it? what if it was a convex curve in it instead? would it have the same effect? I checked my preliminary calculation (I do not insist on this option, just wanna know what is wrong with it, except a higher ), edge tension is not zero (no edge buckling), and the center safety factor is not less than 8.7 (in our case 10/1.15 => here 1.15 is our accepted reduction in safety factor of local points).

"sorry I didn't understand this part: "You may inherit a 3 for1 belt assembly

I guess repeating the 1meter spaced carrying ilders is also poor judgment in design. just saying something is wrong is not enough. there has to be a good reason. and one of my methods in learning is asking/posting. To me, discussing a poor judgment is not a bad idea, when someone learns something through that.

you are right about the 3-4% sag in running, although during drift it is permissible, which is not our case. I have seen even 5% sag for accel./decel. in the manual of a famous conveyor design software!! in the case I mentioned, sag for the rest of the conveyor is about 1%. you know, to limit the sag in the unsupported area, take up is way more than needed, and so the belt is one rating higher than in the normal idler arrangement case.

I must have mentioned that this was one of the proposed ideas. probably you might agree that investigating many solutions (even poor ones) is not a distrust maker!

" At 4% sag, the belt trough becomes distorted and may lead to spillage" . as i said in another reply, I believe that formulas are not everything and I really value experience. (thank you for sharing yours)

I checked, spillage was not a problem, according to the formulas (which might not have been derived for this idler arrangement, I found no note for its limiation) I assume you mean that formula does/might not apply here.

Cheers, ■

Remote Cleaning?

When a tripper reaches the drive end of a yard belt the top strand is empty and the idlers can be minimised. That much is true. Those idlers can be used for spares because they have hardly worked and and they are already at site.

If you accept 2% sag over 3m idler pitch my answer would still be the same.

Persevere with the layout: it will help you more than messing around with sag. As others have mentioned you will have to clean up considerable spillage. Going back to plant layout: how would you propose to access the regular and extensive cleaning operation? If you can't clean it it shouldn't be there. End of story. It wouldn't be a conveyor's Rse. Sorry, I shouldn't have said that...because...it would be a conveyor's Rse. We see those all the time. ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Re: Belt Sag And Belt Life

I think the preliminary speed is around 2.6 m/s, not sure though. but am sure that fill% of the design capacity is(/must be) less than 70; and considering the 1.2 ratio for design capacity/working capacity, working %fill would be around 60%. I'll need to recheck it.

Thank you for the sketch; I will show it to the engineer in-charge.

Regards, ■

Re: Belt Sag And Belt Life

If you accept 2% sag over 3m idler pitch my answer would still be the same.

Persevere with the layout: it will help you more than messing around with sag. As others have mentioned you will have to clean up considerable spillage. Going back to plant layout: how would you propose to access the regular and extensive cleaning operation? If you can't clean it it shouldn't be there. End of story. It wouldn't be a conveyor's Rse. Sorry, I shouldn't have said that...because...it would be a conveyor's Rse. We see those all the time.

Hi john,

well, actually there is a somewhat simple solution, and that is changing some part of the layout, which the owner is not happy about it! perhaps if we rule out other solutions he will agree on that. but we have to have answers/reasons.

I am trying to figure out when that "spillage" happens/how to predict it and when that "cleaning" is needed. so far, the equation says it is not a problem; I think experts here are concerned with the applicability of the equation for the presented case. without a mathematical model, I would have to rely on the experiences of experts like you.

Regards, ■

Re: Belt Sag And Belt Life

href="showthread.php?p=87632#post87632" rel="nofollow">

Thank you for the sketch; I will show it to the engineer in-charge.

Regards,

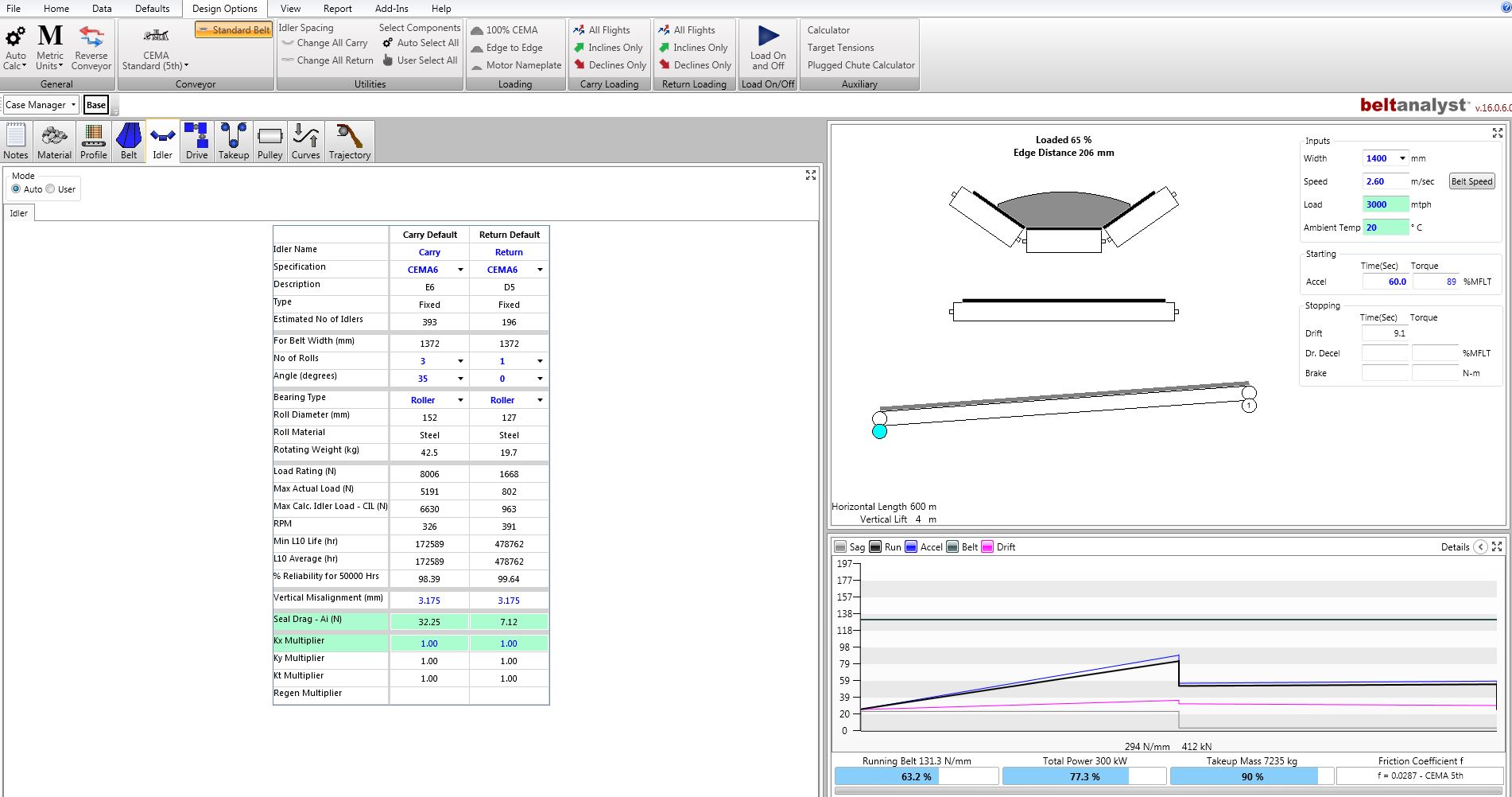

Now that we know the speed we can come up with a fill%. I use Belt Analyst and entered your info (I assumed a lift of 4 meters) and it shows 65% fill with 35 degree idlers. The software will not allow the carry idlers to be flat but changing it to just 20 degree makes it 82% and if it were to go flat I would think you would end up with some spillage even if the belt were to maintain 100% centerline but we all know that wouldn't happen in the real world. Here are snipits from the program.

Attachments

■

Gary Blenkhorn

President - Bulk Handlng Technology Inc.

Email: garyblenkhorn@gmail.com

Linkedin Profile: http://www.linkedin.com/in/gary-blenkhorn-6286954b

Offering Conveyor Design Services, Conveyor Transfer Design Services and SolidWorks Design Services for equipment layouts.

Re: Belt Sag And Belt Life

.."that is changing some part of the layout, which the owner is not happy about it! perhaps if we rule out other solutions he will agree on that. but we have to have answers/reasons..."

For my money these 2 statements say it all. Just let your 'engineer in charge' read some established conveyor literature and let him and the Owner decide if they want to publish new conveyor theory. Suggesting 5m is an acceptable idler pitch implies that for almost a century the conveying fraternity has been taking customers to the cleaners. If 5m pitch can replace eg 1.25 pitch then we have been oversupplying rollers to all and sundry. If it works in one spot then it works everywhere. Or what? How many reasons do these guys need? By the by, what roller life can we expect from this new business venture which suggests to take over the conveying business? Where would the world use the 75% of idlers, that's quite a few when you think about it, that could be discarded if your 'engineer in charge' and the Owner published their own answers/reasons. ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Got The Point

Hello Gary,

Thank you very much for your enlightening reply/reasons.

Now I have few reasons:

1- trough belt section changes over the unsupported length (although I dont think it will be flat in the middle) and that would increase the risk of spillage. I believe there is no simple equation for that, and perhaps if someone needs to make sure of the section, FEM analysis of the orthotropic belt material shall be done.

2- long unsupported distance decreases the lateral stability of the loaded belt (as the section changes) and belt might turn over (twist) partly and spillage ...

3- limiting sag over a long distance requires heavy takeup, which might also increase belt rating

Great!

Thank you again ■

Thanks Anyway

For my money these 2 statements say it all. Just let your 'engineer in charge' read some established conveyor literature and let him and the Owner decide if they want to publish new conveyor theory. Suggesting 5m is an acceptable idler pitch implies that for almost a century the conveying fraternity has been taking customers to the cleaners. If 5m pitch can replace eg 1.25 pitch then we have been oversupplying rollers to all and sundry. If it works in one spot then it works everywhere. Or what? How many reasons do these guys need? By the by, what roller life can we expect from this new business venture which suggests to take over the conveying business? Where would the world use the 75% of idlers, that's quite a few when you think about it, that could be discarded if your 'engineer in charge' and the Owner published their own answers/reasons.

Dear John,

Thank you for following the thread. It is nice to know your idea.

yes, money talks!

people do many things, including believing that the earth was the center of the universe for over 1000 years. suggesting 5 meters idler pitch is not that crazy!!

I am not looking for a new conveyor theory, i am just looking for reasons. saying that many have done something will not convince many others.

I guess your statement about idler pitch must be true even for 1.3m. why not 1.5m, or even 2.5m? less rollers means less money, but that is just for idlers. what about the rest (belt/take up/structure)?

I checked the net for idler spacing and found cases of idler pitch close or even greater than 2 meters. so, yes. it has worked somewhere, but it will not be used everywhere. most probably that is money too.

don't you agree that we learn something new when we push our boundaries, even if that means making mistakes?

I found the following link, you might find it interesting, part of it is about different/optimum idler spacing (e.g. over 2m pitch for overland conveyors)

http://www.doublearrowbelt.com/clien...erformance.pdf

I appreciate your concern and I will try harder to learn/read more established conveyor literature. staying where I am is not a good idea.

Cheers, ■

Please Reveal It

Thank you. On reflection, as a reviewer, I admit that I have observed many cases where the existing recommendations to stagger idler spacing along long centred conveyors had not been implemented. This was often due to there being more obvious errors in other parts of the machine which would have been disastrous and had to be rectified at all stages. Success in these modifications caused me to ignore the staggered idler spacing issue on the grounds that firstly; there would be great reluctance to implement the additional changes after a recent 'provisional approval' and secondly; combined influences of project delay, at whatever cost, and an extra workload for myself. Such is the lot of an independent reviewer.

In your particular case it seems obvious that you are knowledgeable and inquiring enough to present your proposal. Although we have collectively expressed great reservation about your particular intent. I urge you to present this particular situation graphically. When we see the proposal we might all learn something and please realise that only the work is criticised, never the worker. Condemn is a word often used but rarely spelled correctly. ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Precedence

Hello,

in fact, there's a precedence which is the runup onto a tripper car, where the unsupported length of the belt is greater than the standard idler pitch.

However, this situation is designed, or should be, very carefully indeed. Furthermore, the specific design solutions feature to be quite proprietory to the respective design entities.

I feel that the crucial point with your design intent is: Who is to take the technical responsibility to a design that is clearly out of bonds of the common design standards?

The only way would be to design a specific solution under exact definition of the real design environment, considering the complexity and interaction of paramenters and and integrating a professional design workforce adequately qualified for the specificalities of this job.

Pls. accept my personal opinion that here a warning seems to be necessary: That a "patchwork of facts and solutions" - approach might compromise the final design. Fact finding from the internet, without face-to-face discussion with a responsibly involved expert and a complete presentation of the circumstances, may simply make void any conclusions to design decisions.

I'd propose to either call for professional support or to truly face the challenge of a "design does not work" situation, complete let's say with a damaged belt and/or damage to installations scenarios, etc.

Regards ■

Re: Belt Sag And Belt Life

Hello,

Please clarify whether the belt is loaded or empty, at unsupported 5 m zone. Your query does not clarify whether you are referring to carrying run or return run. In case of belt conveyor, such unsupported belt issue can only be at following locations (unless created by unusual reasons).

Carrying run: Concave radial zone at tripper (or tripper of stacker - reclaimer machine). At such location the empty belt lift up (unsupported zone length) can be quite large compared to 5 m. Such lift may still be within idler trough and less visible.

Return run: Horizontal loop take-up of very large stroke (either gravity or winch type). This can also be an issue at belt turn over.

Belt life versus sag is a very general and comprehensive topic and cannot be attended casually. Based on hundreds of years of experience, conveyor engineers have concluded that as a general rule, sag value should be within 1% or 2% for application engineering. So it appears in DIN / ISO / etc. In certain situation and necessity one can also take sag upto 3%, etc. if it helps to reduce radius, etc. However at the same time, he has to consider its implication on conveying friction coefficient for its increase.

As for general information, about 45 years ago, the 100 km long conveying system supplied by German company has carrying idler spacing upto 4 m and return idler spacing of 8 m (as per their leaflet).

Ishwar G. Mulani

Author of Book: ‘Engineering Science And Application Design For Belt Conveyors’. Conveyor design basis ISO (thereby book is helpful to design conveyors as per national standards of most of the countries across world). New print Nov., 2012.

Author of Book: ‘Belt Feeder Design And Hopper Bin Silo’

Advisor / Consultant for Bulk Material Handling System & Issues.

Pune, India. Tel.: 0091 (0)20 25871916

Email: conveyor.ishwar.mulani@gmail.com

Website: www.conveyor.ishwarmulani.com ■

Re: Belt Sag And Belt Life

.........Belt life versus sag is a very general and comprehensive topic and cannot be attended casually. Based on hundreds of years of experience, conveyor engineers have concluded that as a general rule, sag value should be within 1% or 2% for application engineering. So it appears in DIN / ISO / etc. In certain situation and necessity one can also take sag upto 3%, etc. if it helps to reduce radius, etc. However at the same time, he has to consider its implication on conveying friction coefficient for its increase.

...........................................

Website: www.conveyor.ishwarmulani.com

Dear Mr.Mulani / Other experts,

I think the above 1% to 2% sagging is the guide line for conventional rubber lagged drive pulley.

Please advise for ceramic lagging.

Regards, ■

Re: Belt Sag And Belt Life

.........Belt life versus sag is a very general and comprehensive topic and cannot be attended casually. Based on hundreds of years of experience, conveyor engineers have concluded that as a general rule, sag value should be within 1% or 2% for application engineering. So it appears in DIN / ISO / etc. In certain situation and necessity one can also take sag upto 3%, etc. if it helps to reduce radius, etc. However at the same time, he has to consider its implication on conveying friction coefficient for its increase.

...........................................

Website: www.conveyor.ishwarmulani.com

Dear Mr.Mulani / Other experts,

I think the above 1% to 2% sagging is the guide line for conventional rubber lagged drive pulley.

Please advise for ceramic lagging.

Regards, ■

Re: Belt Sag And Belt Life

Hello,

Referring to the posting by Shri Ganesh, some information is as below:

A) The requirement of minimum tension in belt to keep sag value less / equal to 1% to 2% (or 3% if one like) is independent of drive pulley lagging type. This requirement pertains to necessity for occurring tension value more than minimum at any point in carrying run as well as return run, so as to uphold the chosen value of conveying friction coefficient.

B) The other requirement of minimum belt tension is at exit point of drive pulley/s so that belt do not slip at drive pulley/s during steady / starting / stopping.

Both the above requirements of minimum tension are than evaluated (calculated) at common reference point. The larger of the minimum is chosen for conveyor design. This will satisfy that sag does not exceed chosen percentage, and at the same time belt will not slip at drive pulley.

As for sag, one can consider sag value some what more during stoppage (if he likes), as it will reduce burden on brake / drive, due to higher frictional resistance arising in conveyor by more sag.

The type of lagging will influence minimum tension required (B) to prevent belt slip on drive pulley.

For particular wrap angle, this minimum requirement (B) will get influenced as below:

Higher value for bare pulley

Less value for herringbone rubber lagging

Lesser value for ceramic lining.

Also friction coefficient between belt and pulley surface can have 3 variants such as dry, wet and clean, wet and contaminated, etc.

For particular conveyor, which type of lagging will translate into overall economy of belt conveyor can be decided after conveyor design (price for belt, drive, pulleys, lagging price, availability, maintenance, etc.).

Regarding belt life versus sag; sag values being used might be taking care of these as an overall practical / realistic solution. I have not come across such data for belt life versus sag. The creation of such data will be very expensive affair, because it requires equipment to create real situation many time and also same should be authentic. Research on bulk material handling equipment is very expensive as compared to test tube type research. Belt carcass life is influenced by many variants such as material, material size, feeding configuration, conveyor length, speed, pulley diameters, pulleys quantity, nature of start-up, idlers features and possibly marginally by sags being used in practice. So the research exercise is likely to be complicated.

Ishwar G. Mulani

Author of Book: ‘Engineering Science And Application Design For Belt Conveyors’. Conveyor design basis ISO (thereby book is helpful to design conveyors as per national standards of most of the countries across world). New print Nov., 2012.

Author of Book: ‘Belt Feeder Design And Hopper Bin Silo’

Advisor / Consultant for Bulk Material Handling System & Issues.

Pune, India. Tel.: 0091 (0)20 25871916

Email: conveyor.ishwar.mulani@gmail.com

Website: www.conveyor.ishwarmulani.com ■

Belt sag and belt life

Dear Experts,

Coming from my previous interest in belt sag, I was just wondering how belt sag can be related to belt life.

What I know:

- more sag means more power consumption, especially for long conveyors (one might keep it below 1%)

- sag can affect idlers' life

- sag might have a considerable effect on the required belt length or take-up travel

- not a good practice to have high sag values in skirtboard zone + dust generation problem!

sounds pretty important already.

aside from the above, I have also heard of unacceptable belt flexure that may reduce belt life. would someone enlighten me on this? is it because of some sort of shear stress between the plies? is it like bending the troughed belt over one roller set?

Problem:

more info:

belt width: 1.4 m

trough: 35 deg

conveyor length: ~600 m (straight -no curve)

capacity: ~3000 tph

material: crushed stone (density ~2.2 t/m3)

Regards, ■