Re: Transition Distance Idler

Many threads on this site relating to transition distance. Here are a couple of them.

href="https://forum.bulk-online.com/showthread.php?23607-How-to-Determine-Transition-Distance" target="blank">https://forum.bulk-online.com/showth...ition-Distance

href="https://forum.bulk-online.com/showthread.php?28357-Another-Transition-Idler-Question" target="blank">https://forum.bulk-online.com/showth...Idler-Question

1. Is this Belt modulus right to for EP500/3? It is typically expressed as kN\m but is is always best to refer to the belt manufacturers technical information.

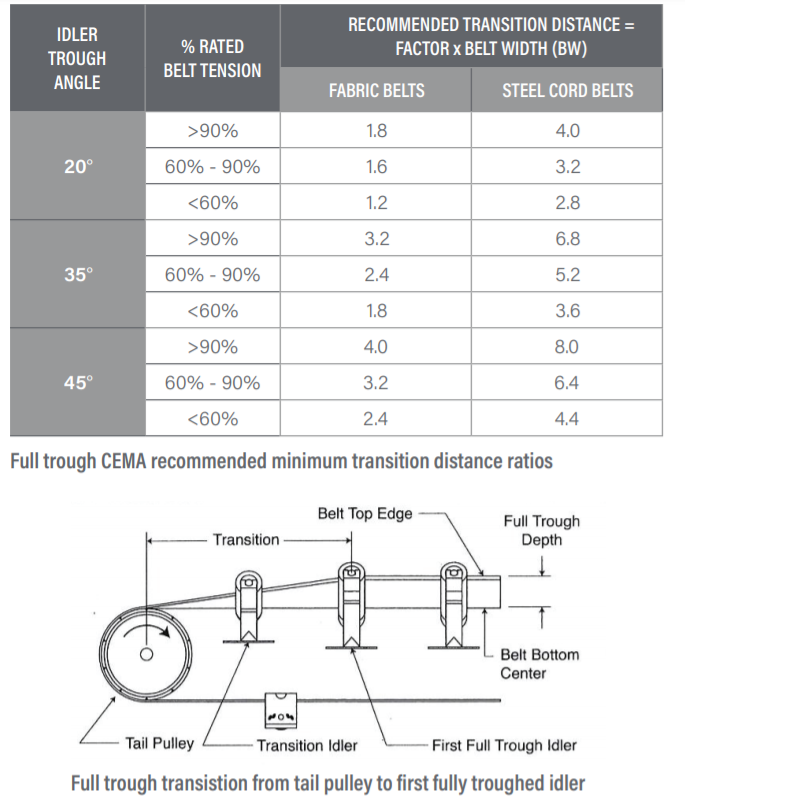

2. What does it mean - % rated tension belt? Every section along a conveyor has different tensions (ie: head pulley area typically has the highest and tail pulley would be much lower) So each location is expressed as a % of the rated tension of the belt.

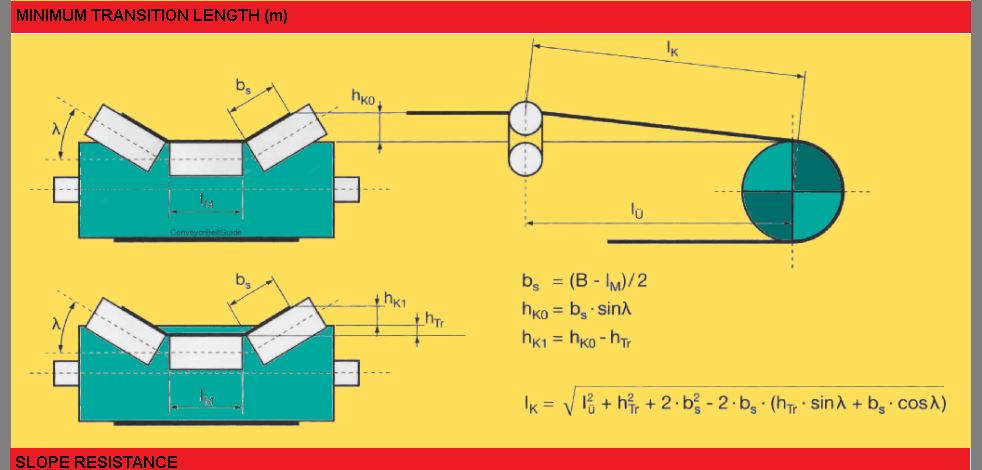

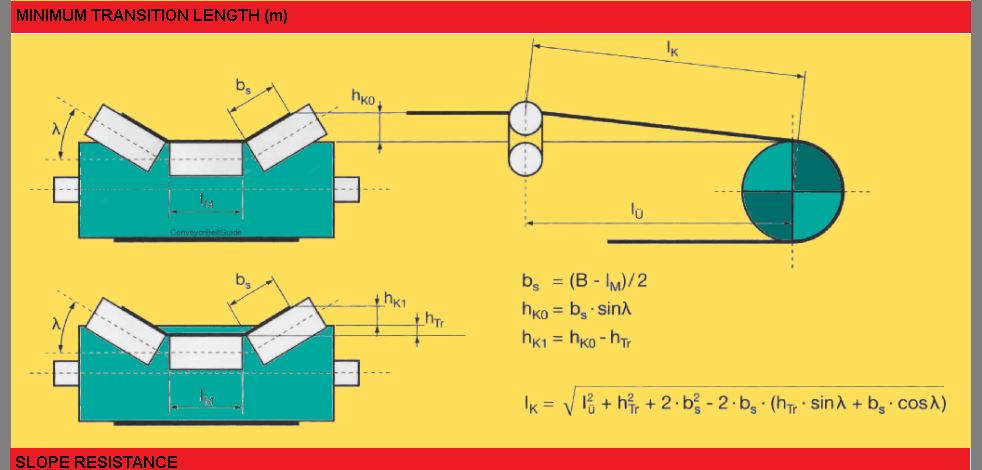

3. Is it OK to use the formula to calculate transition distance Lb = 0.707 x h x (E / delta S)^(1/2), where E- Belt Modulus, delta S - 0.25 x Smax, h - vertical distance from flat belt surface to trough edge of the belt! A much simpler formula would be as shown in the attached picture. B= belt width in mm.

Attachments

■

Gary Blenkhorn

President - Bulk Handlng Technology Inc.

Email: garyblenkhorn@gmail.com

Linkedin Profile: http://www.linkedin.com/in/gary-blenkhorn-6286954b

Offering Conveyor Design Services, Conveyor Transfer Design Services and SolidWorks Design Services for equipment layouts.

Re: Transition Distance Idler

Thanks Gary for the reply!

1. OK

2. Not sure about that, let's assume we have tension T1 at the head pulley, so I believe rated tension belt should be calculated ( T1 / Z ) x 100%, but what this Z is then? or am I missing something?

3. Not sure about that formula, as I have full through belt, so Ik = (Io^2 + 2*bs^2) but then I have to assume Io which I am looking for, or can I assume angle of transition?

Gary, I am trying to calculate from the recommendations of CEMA but I am not quite sure what & rated belt tension is.

href="https://forum.bulk-online.com/attachment.php?attachmentid=48163&d=1620028653" title="Name: Transition Idler Formula.pngViews: 58Size: 183.8 KB">Transition Idler Formula.png ■

Re: Transition Distance Idler

When you calculate the tensions in a conveyor belt system, you determine the highest and the lowest tension. There are other tensions to consider as well but let's just keep this as simple as possible. The highest T1 is considered as the "rated tension" of the system and all tensions lower than that are a percentage of the rated tension.

So for a simple example: If the belt at the head pulley has the highest tension and that tension was 20KN and the at the tail pulley has a tension of 8 KN. The belt at the tail pulley has a tension of 40% of the rated tension. I hope that makes sense. ■

Gary Blenkhorn

President - Bulk Handlng Technology Inc.

Email: garyblenkhorn@gmail.com

Linkedin Profile: http://www.linkedin.com/in/gary-blenkhorn-6286954b

Offering Conveyor Design Services, Conveyor Transfer Design Services and SolidWorks Design Services for equipment layouts.

Re: Transition Distance Idler

Thanks Gary.

Now I understand everything what I need.

Once again Thanks! ■

Transition Distance Idler

Hello there,

Could anyone help me to explain some issue in regard to Transition Distance.

Data:

- Belt EP500/3 , Belt modulus 6250 N/mm

- Smax (Starting) - circa. 10 kN

- Operating Tension - circa. 7 kN

- 35 deg idlers angle

- 650mm belt width

My questions are:

1. Is this Belt modulus right to for EP500/3?

2. What does it mean - % rated tension belt?

3. Is it OK to use the formula to calculate transition distance Lb = 0.707 x h x (E / delta S)^(1/2), where E- Belt Modulus, delta S - 0.25 x Smax, h - vertical distance from flat belt surface to trough edge of the belt!

If anyone could help I would appreciate that! ■