Grinding And Classification Equipment And Toll Processing

Suggest contacting Micro Grinding Systems

(501) 374-8402

www.microgrind.com

Irl Sanders ■

Re: Quartz Grinding And Classifying

OME Malaysia has for mission the engineering of-the art ultra-fine classifying, grinding and coating of minerals.

We are dedicated to produce air classifiers, pin-mills, ball-mills and wet pearl mills.

Constant innovation on our classifiers has lead to sharper cuts, less maintenance and the ability to produce minerals of d98<8µm.

We can supply you with finest quality equipment at a good price we have experience in the field and had already installed many plants in Malaysia, Thailand and Saudi Arabia.

Please fill free to send your enquiries and we will be happy meet you and discuss your project.

Hayayoo@yahoo.com

Marketing Manager ■

Re: Quartz Grinding And Classifying

Please do not hesitate to contact Ecutec S.L..

We are specialist in grinding and classifying systems for minerals, our experience also in designing whole processing plants is at your disposition.

Please contact us:

d.kneissler@ecutec.es

By the way our machinery is exclusively produced in Germany.

Thank you.

rgds

Dietmar Kneissler

Sales Director ■

Re: Quartz Grinding And Classifying

Quartz belongs to the hard minerals. It is used mainly in the ceramic and glass industry as a raw material. Therefore any contamination with other elements shall be avoided. This can be realised by dry grinding with ball mill in combination with classifier. The finest Quartz flour present on the market is 97 % < 8 micron. This is produced with an Alpine Turboplex Classifier.

Please contact Robert Rosen for more information

r.rosen@alpine.hosokawa.com ■

Alumina Ball For Dry Grinding Quartz

Pls first check the technical specification for our high alumina grinding media ball as the following:

1) 92% alumina grinding ball

Al2O3: 92% Min.

Fe2O3: 0.25% Max.

Mohs Hardness: 9

Water absorption: 0.02% Max.

Density: 3.60 g/cm3 Min.

EWT: 0.15 Max.

2) 95% alumina grinding ball

Al2O3: 95% Min.

Fe2O3: 0.20% Max.

Mohs Hardness: 9

Water absorption: 0.02% Max.

Density: 3.65 g/cm3 Min.

EWT: 0.10 Max.

If your grinding work mode is batch grinding, then 92% alumina grinding ball is O.K., if your grinding work mode is continuous grinding, then 95% alumina grinding ball is most recommended.

For more details, pls kind visit:

URL: http://www.alumina-ball.com/

BLOG: http://www.alumina-ball.com/blog/ ■

Quartz Ultra Fine Grinding

Dear Mr. Morag,

Cyclotec can provide dry quartz grinding P50 18-20 microns, and P80 45 microns

WITHOUT CLASSIFICATION

( 96% silica content, silica sand feed F80 630 microns, topsize 5 mm)

The biggest mill we have can provide 3 ton/hour capacity at mentioned above specs.

Also if to turn the product to second mill run = P50 9-10 microns, P80 25 microns

WITHOUT CLASSIFICATION

Total power consumption will be 15-18 kW/ton for each mill run

See film demo at link below

Please let me know if you need further info.

Ezry Akkerman

Cyclotec Ltd

http://www.cyclotec.net/?page=servic.../actconmills

cyclotec@gmail.com ■

Grinding Systems

Please do not hesitate to contact CEMTEC Cement and Mining Technology GmbH.

We are specialist in grinding systems for minerals and bulk materials.

Visit also www.cemtec.at ■

Quartz Sand Grinding Mill And Spiral Classifier

For quartz sand grinding you can choose quartz sand grinding mill,but before grinding ,you may have to crush the stone into proper size,so crusher machine are needed.

For quartz sand classifying, spiral classifier is a good choice. ■

Re: Quartz Grinding And Classifying

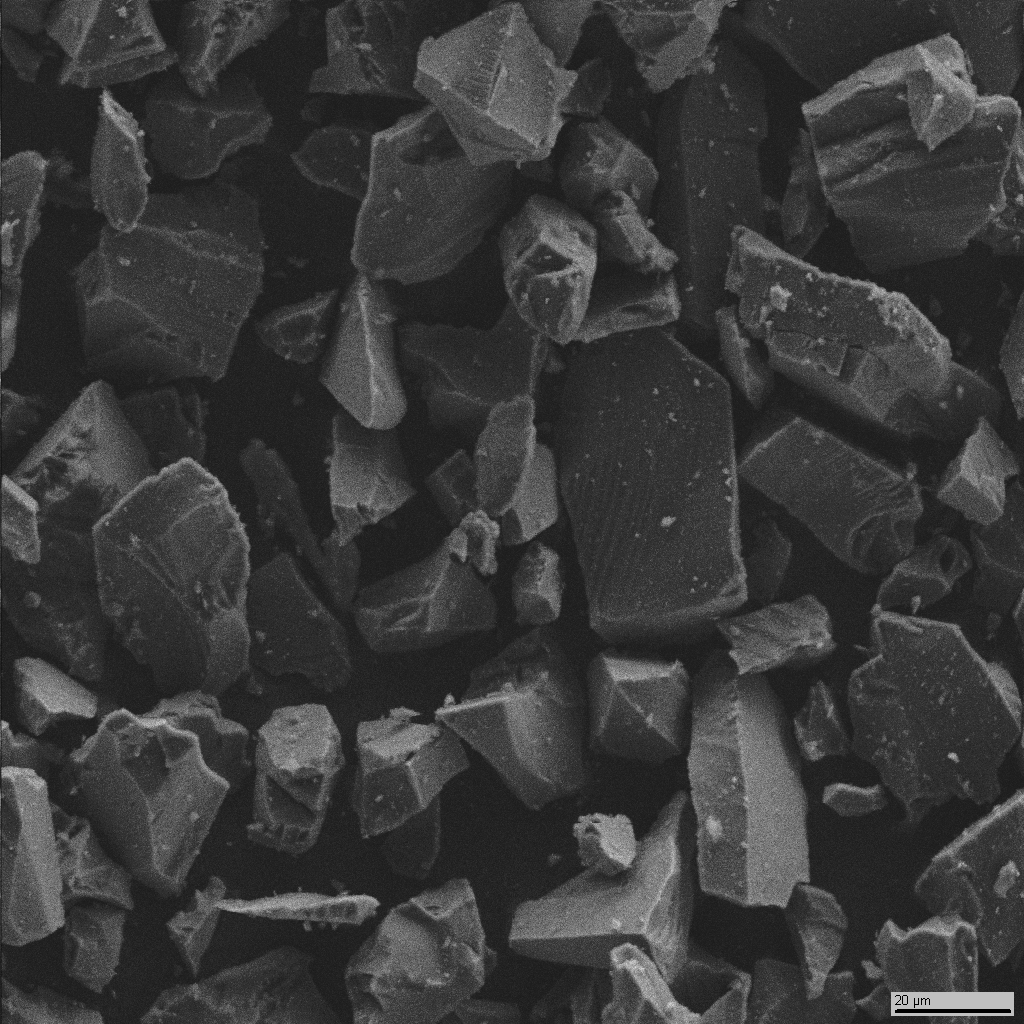

Quartz of narrow fraction 10µm-50µm.

Best Regards,

Group of Leotec Companies Ltd.

Andrey Chumokhvalov

Video;

href="http://www.youtube.com/watch?v=3EeZpKOuqWI" target="blank">http://www.youtube.com/watch?v=3EeZpKOuqWI

href="http://leotecltd.com/leftmenu/planetarymill/" target="blank">http://leotecltd.com/leftmenu/planetarymill/

href="mailto:andrey.chumokhvalov@leotec.ru">andrey.chumokhvalov@leotec.ru

Attachments

quartz 10µm-56µmJPEG:forum_attachments/file_container/quartz 10µm-56µm.jpg (BMP)

■

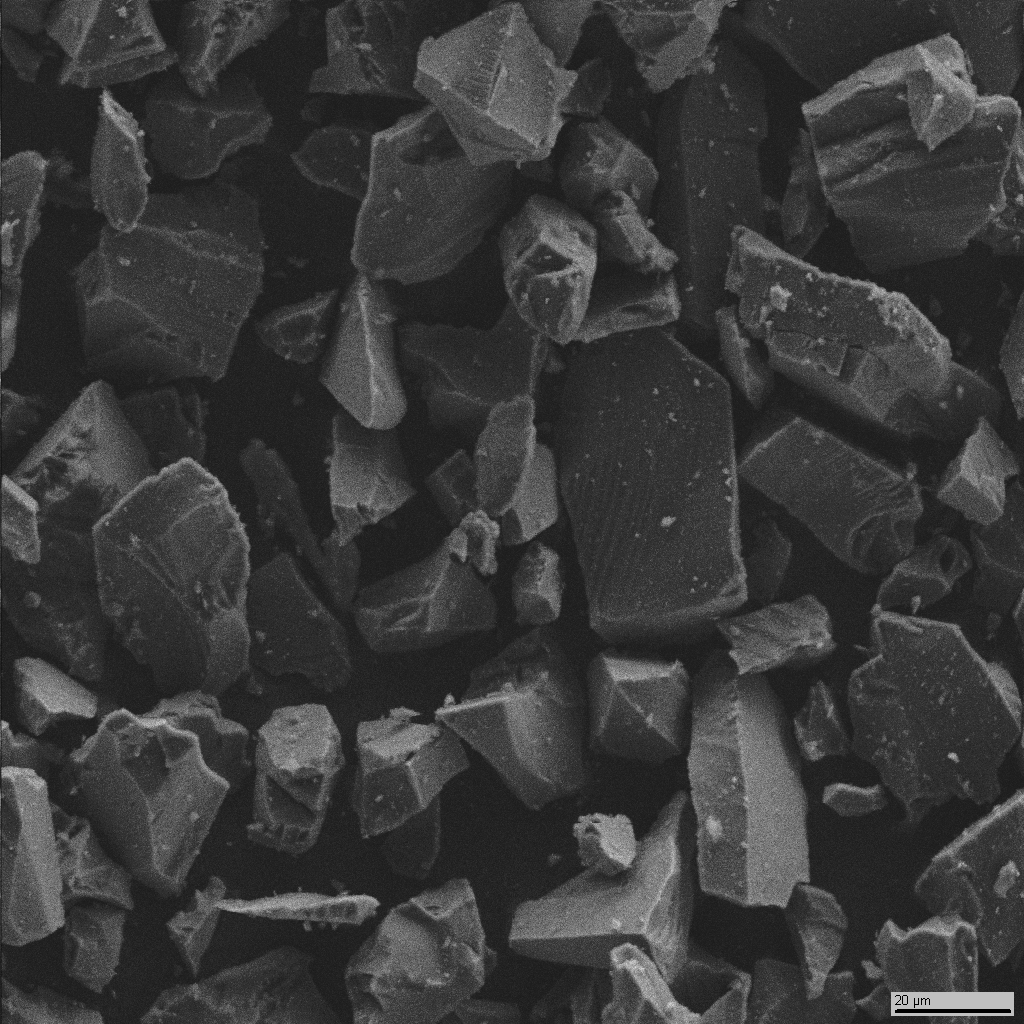

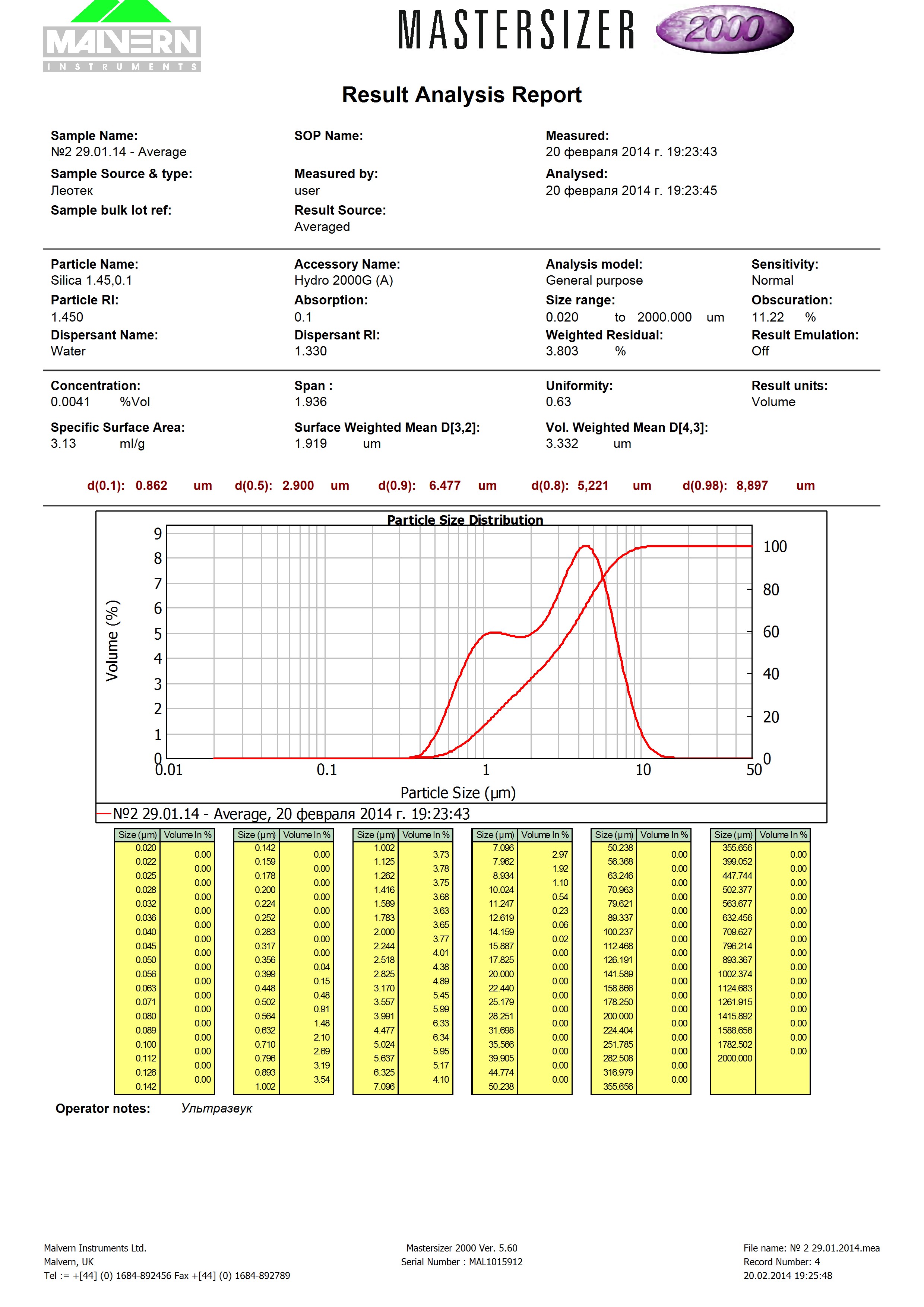

Re: Quartz Grinding And Classifying

Leotec-PCM

Quartz of narrow fraction 50µm-56µm.

Quartz P50=6µm

Best Regards,

Group of Leotec Companies Ltd.

Andrey Chumokhvalov

Video; http://www.youtube.com/watch?v=3EeZpKOuqWI

http://leotecltd.com/leftmenu/planetarymill/

andrey.chumokhvalov@leotec.ru

Attachments

quartz 50-56umJPEG:forum_attachments/file_container/quartz 50-56um.jpg (BMP)

quartz p50=6umJPEG:forum_attachments/file_container/quartz p50=6um.jpg (BMP)

■

Quartz Grinding And Classifying

New data of grinding balls and mill lining consumption was obtained while grinding crystalline quartz in the PCM Leotec.

Feed material - quartz F90 = 100 microns (Kyshtym mining processing plant).

Two final products:

1. P90 = 13 microns - 85% of feed material.

2. P90 = 2.11microns - 15% of feed material.

Grinding balls consumption - 1 kg / ton of a source product.

Lining wear - 240 grams / ton.

Best Regards,

Group of Leotec Companies Ltd.

Andrey Chumokhvalov

Video; http://www.youtube.com/watch?v=3EeZpKOuqWI

http://leotecltd.com/leftmenu/planetarymill/

andrey.chumokhvalov@leotec.ru

Attachments

■

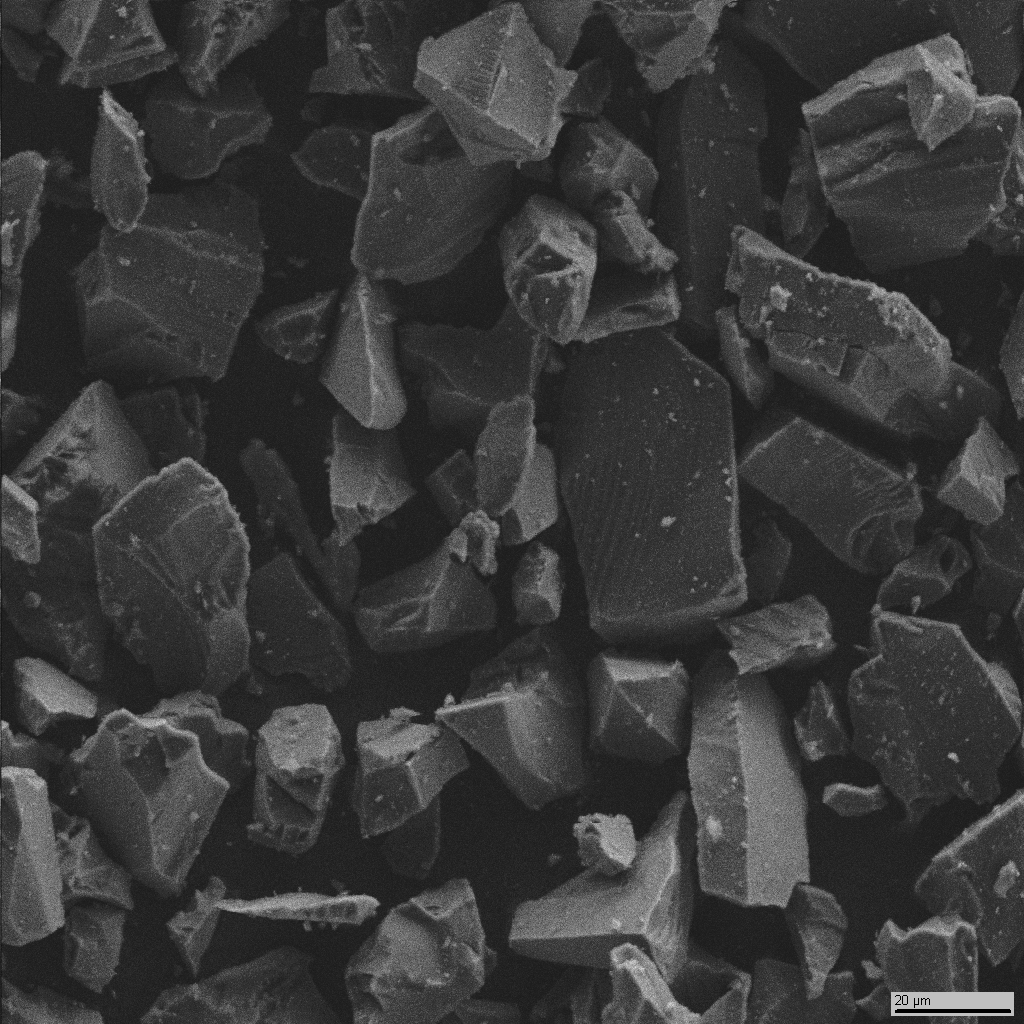

Re: Quartz Grinding And Classifying

Still one step to the nano- grinding In the continuous process (60 kg/h).

"Leotec" will participate in the exhibition - POWTECH 2013.

We will show "PCM-50-nano".

Best Regards,

Group of Leotec Companies Ltd.

Andrey Chumokhvalov

Video; http://www.youtube.com/watch?v=3EeZpKOuqWI

http://leotecltd.com/leftmenu/planetarymill/

andrey.chumokhvalov@leotec.ru

Attachments

quartzJPEG:forum_attachments/file_container/quartz_1.jpg (BMP)

■

Re: Quartz Grinding And Classifying

"PCM-50-nano". Following step to the nano- grinding.

Best Regards,

Group of Leotec Companies Ltd.

Andrey Chumokhvalov

Video;

href="http://www.youtube.com/watch?v=3EeZpKOuqWI" target="blank">http://www.youtube.com/watch?v=3EeZpKOuqWI

href="http://leotecltd.com/leftmenu/planetarymill/" target="blank">http://leotecltd.com/leftmenu/planetarymill/

href="mailto:andrey.chumokhvalov@leotec.ru">andrey.chumokhvalov@leotec.ru

Attachments

1-3-1JPEG:forum_attachments/file_container/1-3-1.jpg (BMP)

■

Planetary Mill

Dear Mr. J. MORAG

Quartz is hard material (8 on Moose scale) and requiers a lot of energy while grinding. We offer best and most effective mills: continous action planetary mills. Energy consumption of grinding in the planetary mill is 20-100 times lower than in the ball or vibration mills. For example grinding of such hard material as quartz to a size P(98)=20 microns requires less than 50 kWh / tonne.

Other advantages of technology are:

• Reduction of production and capital costs. Grinding costs 5-10 times lower than any of the existing methods.

• Grinding in dry and wet modes.

• Ability of complete cleaning of the mill.

• Small size, mobility.

• Minimum need for expendables. High performance with small overall dimensions can reduce the cost of liners and grinding media.

• Sustainability, no vibrations. The mill does not require a foundation.

• The best opportunities for mechanical activation. The technology allows to change the properties of many materials, revealing their new opportunities

■

Re: Quartz Grinding And Classifying

Our new modest result of the quartz separation.

href="https://forum.bulk-online.com/attachment.php?attachmentid=39245&d=1394091479" id="attachment39245" rel="Lightbox82167" target="blank">■

Re: Quartz Grinding And Classifying

New test with the quartz sand in PCM50.

Overloads 60G, productivity 80 kg/h, F50=0,4mm, the dry process, one pass.

Best regards,

Andrey Chumokhvalov.

Attachments

quartz sand overloads 60g, productivity 80 kg in h (JPG)

■

Ceramic Balls

We supply kinds of alumina ceramic balls:

http://aluminaceramics.blog.com

www.cbcceramics.com ■

Alumina Ceramics, Zirconia Ceramics & Zta

Wear resistant ceramics & ceramic grinding media - alumina ceramics, zirconia ceramics & ZTA

https://wordpress.com/home/aluminace....wordpress.com ■

Quartz Grinding and Classifying

I am looking for quartz grinding and classifying producers.

Many thanks in advance.

J. MORAG ■