Re: Pneumatic Conveyor For Drying Machine

Dear Glenn,

First of all, the figure is missing.

Pneumatic conveying of hulled rice is mostly damaging the rice by collisions against each other and the wall (especially in bends).

Therefore, the absolute minimum velocity must be maintained under all circumstances.

A centrifugal fan has an operating curve, whereby the air flow changes significantly with the pressure and therefore the velocity will change also significantly.

A low pressure drop design will keep the air velocity within the desired range.

(which is still not a guarantee for deterioration free conveying)

A venturi is a bad choice in this respect, as a venturi is based on giving the air a high impulse (high velocity), which is converted in rice velocity and recovered pressure for conveying.

500 kg/hr is not much.

Looking at your calculation results, the distance cannot be long.

Why not opt for a mechanical conveyor?

Have a nice day ■

Teus

Re: Pneumatic Conveyor For Drying Machine

Dear teus

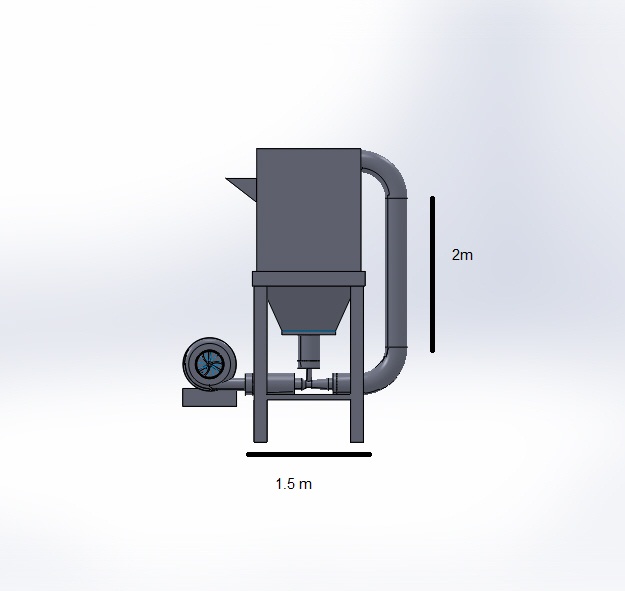

i'm sorry for the figure, i think it has attached. here the figure for the layout of pipeline

and specification of the centrifugal fan

it is a circulating drying machine so i think the best choice for the material mover is a pneumatic conveyor.

thanks

glenn ■

Re: Pneumatic Conveyor For Drying Machine

Dear Glenn,

1)There should be a filter between the silo intake and silo exhaust. Otherwise the generated dust is blown into the environment.

2)A venturi/eductor as feeder could be possible, but with a higher pressure than a centrifugal fan can generate.

A venturi cools down, whereby condensation can take place, which is not a good thing when you want to dry a material. A rotary valve might be better.

How is your drying process working when the ambient RH is close to 100%.

May be the rice is then getting wetter.

Success ■

Teus

Re: Pneumatic Conveyor For Drying Machine

Dear teus

Thanks for the advice, i will consider to add a filter in the system.

And yes, i just realize that a venturi have that problem, and i will replace it with a rotary valve. But to keep it a low power consumption can i just replace it with a T bend for the feeder?

And the next question : Is my calculation for minimum pressure and airflow correct?

Thanks

Glenn ■

Re: Pneumatic Conveyor For Drying Machine

Dear Glenn,

I certainly would not use a centrifugal fan as conveying air compressor.

The air flow delivery of the centrifugal fan changes too much with the pressure.

Using a lobe blower of 0.12 m3/sec (7 m3/min), I calculate a conveying pressure of approx. 700 mmWC.

The air velocity is then between 17 m/sec to 20 m/sec, and the rice velocity is then 5.2 m/sec to 5 m/sec.

However, the first bend (horizontal to vertical) slows down the rice to a very low velocity (approx. 0.04 m/sec), close to choking in the bend.

This is caused by the assumption that in the bend, air and material is 100% separated and that the rice slides through the bend by the impulse at entering the bend.

In a bend from horizontal to vertical, the friction along the outer wall is increased by the gravity component and the rice is decelerated by the other gravity component.

Gravity is retarding the rice in 2 ways, which occurs only in a bend from horizontal to vertical.

To guarantee choking free conveying, the air flow should be approx. 0.29 m3/sec at approx. 750 mmWC.

However, the air velocity has then increased to approx. 44 m/sec and the rice velocity has then increased to approx. 9.5 m/sec. (Normal velocities in grain unloaders)

Still the problem of RH and the temperature of the conveying air (70 degr) of the conveying air and the resulting drying effect is not assessed.

Consult a drying specialist

Take care ■

Teus

Re: Pneumatic Conveyor For Drying Machine

Dear teus

Thanks for your help, i will re design the system based on your calculation.

Could you tell me how to calculate the velocity of the rice?

Thanks

Glenn ■

Re: Pneumatic Conveyor For Drying Machine

Dear Glenn,

Forgot to mention:

(pipe material is PVC)

This will cause static electricity and probably sparks when the electric charges are equalized.

The application of a rotary blow by valve requires a somewhat bigger conveying air compressor, to compensate for the rotary lock air leakage.

Have a nice day ■

Teus

Re: Pneumatic Conveyor For Drying Machine

Dear Glenn,

Thanks for your help, i will re design the system based on your calculation.

My calculation is just a rough estimate and the first bend problem might cause the design to be incorrect.

I still strongly advise to consult a manufacturer of such drying systems.

Do not take the risk yourself.

Be careful, ■

Teus

Re: Pneumatic Conveyor For Drying Machine

dear teus

thanks for your help, i will re design my system. and i will replace a PVC as pipeline. thank you very much

my regards

glenn ■

Re: Pneumatic Conveyor For Drying Machine

dear teus

i re design the system, but i can't find the value of K (friction multiplier) for the system, can you tell me the value for this system?

thanks.

glenn ■

Re: Pneumatic Conveyor For Drying Machine

Dear Glenn,

The value of K (friction multiplier) is related to the used calculation algorithm and is derived from field measurements, which are

re-calculated by the same algorithm.

Furthermore, the friction multiplier factor K is a function of the Solid Loading Ratio and the Reynolds number.

The supplier of your software should know the K factor or you have to determine the K factor yourself by experiments with the same material that you want to design for.

As the K value is depending on the Re-number, scaling is not an option.

Be careful, ■

Teus

Pneumatic Conveyor for Drying Machine

hello

i design a positive discharge of pneumatic conveyor for a drying machine, the material is rice hulled (753 kg/m3) to be conveying 400-500 kg/hour. the layout of pipeline is in the figure below, and the bore of pipe is 4 inch (pipe material is PVC)

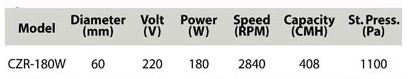

the requirement for this design is a low power consumption (<450 watt electricity). so i think a centrifugal fan could be a good choice. based on my calculation the pressure should be 1000 pa, and the air velocity is 15 m/s. i choose a centrifugal fan with the spec below.

the question is:

1.) is my calculation correct?

2.) is the blower that i choose is good?

3.) which is better a venturi feeder or a T bend for the feeding device?

thanks for the advice (and sorry for my bad english)

glenn ■