Re: Pet Pellets Dense Phase Conveying

Dear carleriksen,

how can one design a system where there is one blower for many different lengths

In principle:

-one blower at constant rpm requires the same pipe diameter(s) for all different lengths, to keep the gas velocity the same in all pipes. Resulting in different conveying rates for each individual conveying route.

-There is an option to install a bigger vacuum pump with a controlled rpm. In that case different pipe diameter(s) could be used. Designing such a system will be more complicated. Resulting in closer conveying rates for each individual conveying route.

The performance of the existing system can be used to verify the pneumatic conveying properties of the conveyed PET pellets.

Any help with design procedures and calculation methods would be greatly appreciated.

Designing and calculating such a project requires, as you said, a calculation method, but also a deep understanding of pneumatic conveying and whether the calculation method is reliable and accurate. (How much does the pneumatic conveying software understands the pneumatic conveying physics).

Consulting a good and experienced company for your project seems a better option.

Take care ■

Teus

Re: Pet Pellets Dense Phase Conveying

Thank you very much for the advice Teus. ■

Comparison On The Basis Of The Same Operating Characteristic (S…

href="showthread.php?p=88448#post88448" rel="nofollow">

In principle:

-one blower at constant rpm requires the same pipe diameter(s) for all different lengths, to keep the gas velocity the same in all pipes. Resulting in different conveying rates for each individual conveying route.

-There is an option to install a bigger vacuum pump with a controlled rpm. In that case different pipe diameter(s) could be used. Designing such a system will be more complicated. Resulting in closer conveying rates for each individual conveying route.

The performance of the existing system can be used to verify the pneumatic conveying properties of the conveyed PET pellets.

Designing and calculating such a project requires, as you said, a calculation method, but also a deep understanding of pneumatic conveying and whether the calculation method is reliable and accurate. (How much does the pneumatic conveying software understands the pneumatic conveying physics).

Consulting a good and experienced company for your project seems a better option.

Take care

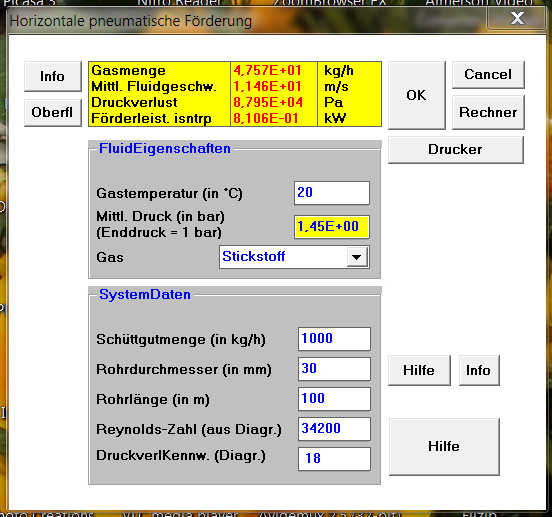

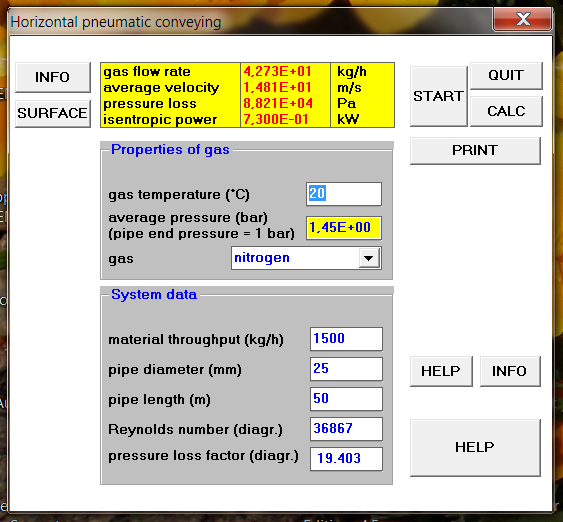

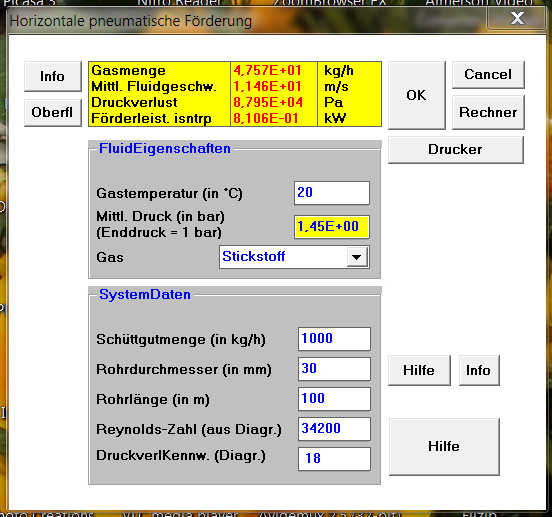

In order to underline the complexity of the physical connections in pneumatic conveying, emphasized by Mr. Tuinenburg, I would like to present the result of a comparison on the basis of the same operating characteristic (shocking) of my state diagram for two pipes of different lengths; wherein pressure loss and gas throughput have approximately the same size.

href="https://forum.bulk-online.com/attachment.php?attachmentid=45532&d=1501681013" id="attachment45532" rel="Lightbox88454" target="blank">■

Re: Pet Pellets Dense Phase Conveying

We have a central vacuum conveying system in place at one of our branches and that we wish to improve before installing a similar system in another branch. We would like to operate in dense phase to avoid producing unnecessary fines.

As it is a central loading system connected to many machines, how can one design a system where there is one blower for many different lengths? The material lines vary from about 50 to 100m with about the same for the vacuum lines. The bulk density is 850+-30 kg/m3 with about 2mm spherical pellets.

Any help with design procedures and calculation methods would be greatly appreciated.

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++ ++++++++++

Dear Carleriksen,

For a central dust collection system such as yours, dense phase conveying is not practical because the conveying velocity must be high enough to entrain the dust particles in the air stream. This velocity will be above the saltation velocity which implies dilute phase.

Creation of more fines should not be a concern because the dust particles are already fine.

A central dilute phase dust collection system can be easily designed using the design method described in my article "THEORY AND DESIGN OF DILUTE PHASE PNEUMATIC CONVEYING SYSTEMS". A single vacuum blower can serve multiple dust pick up points with a network of conveying lines.

Regards,

Amrit Agarwal

Pneumatic Conveying Consulting

email: polypcc@aol.com ■

Addition

My calculation should show on the one hand how pipe length affect tube diameter and bulk material throughput. In addition, I would like to draw attention to the fact that the operating data of two comparable industrial plants published in Bulk-Online and discussed by me are situated in the dilute phase area. One of these in the pressure loss minimum, the second at the upper limit (shoking). ■

PET pellets dense phase conveying

Hi all

We have a central vacuum conveying system in place at one of our branches and that we wish to improve before installing a similar system in another branch. We would like to operate in dense phase to avoid producing unnecessary fines.

As it is a central loading system connected to many machines, how can one design a system where there is one blower for many different lengths? The material lines vary from about 50 to 100m with about the same for the vacuum lines. The bulk density is 850+-30 kg/m3 with about 2mm spherical pellets.

Any help with design procedures and calculation methods would be greatly appreciated. ■