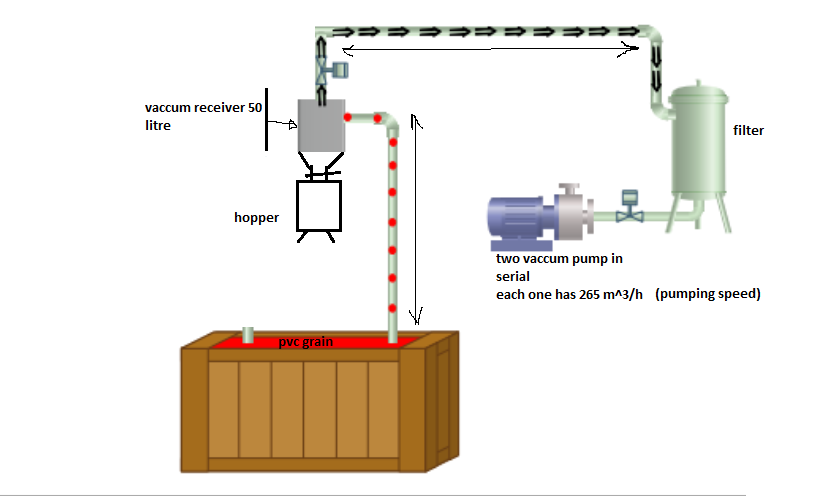

Installtion Shematic

installtion shematic

href="https://forum.bulk-online.com/attachment.php?attachmentid=45567&d=1520930191" title="Name: capture2.pngViews: 144Size: 47.4 KB">capture2.png ■

Re: Help Pvc Grain Pneumatic Conveying System Vaccum

Dear mouadrabihsenhaji,

Without installation- and performance data, it is impossible to answer your question.

At least required are:

-Pipe diameters

-Lengths horizontal

-Length vertical

-Operational conveying rate with corresponding vacuum

-Vacuum pump type

From your picture, it is impossible to derive that information.

That you show 2 vacuum pumps in series, could indicate, that you use 2 centrifugal fans in series to reach the required pressure drop.

In that case, the fan curves are also required.

The installation could work at a longer distance with a higher vacuum or a lower conveying rate.

Seems to be a small installation anyway, so, why not just try it?

Calculating the pick-velocity of the pvc grain is done through dividing the airflow, corrected for the absolute pressure at the intake by the cross-sectional area if the intake pipe.

Take care ■

Teus

Re: Help Pvc Grain Pneumatic Conveying System Vaccum

Without installation- and performance data, it is impossible to answer your question.

At least required are:

-Pipe diameters

-Lengths horizontal

-Length vertical

-Operational conveying rate with corresponding vacuum

-Vacuum pump type

From your picture, it is impossible to derive that information.

That you show 2 vacuum pumps in series, could indicate, that you use 2 centrifugal fans in series to reach the required pressure drop.

In that case, the fan curves are also required.

The installation could work at a longer distance with a higher vacuum or a lower conveying rate.

Seems to be a small installation anyway, so, why not just try it?

Calculating the pick-velocity of the pvc grain is done through dividing the airflow, corrected for the absolute pressure at the intake by the cross-sectional area if the intake pipe.

Take care

hello sure thank u for your answer

Centralized conveying system

the installation like shown in the shematic ...we have pip installation from the pump to the filter then from the filer to the vaccum receiver

then from the vaccum receiver to pickup point .

-----------------------------------------------------------------

Lenght :

-From the pump to the vaccum receiver

Length vertical 3 m

horizental 80 m

-From the vaccum receiver to the pickup point

horizental: 70 m

vertical : 3 m

--------------------------------------------------------------------

two pump in serial each one of them has 265 m^3/h (pumping speed)

- Pipe diameters : 50 mm

-Operational conveying rate with corresponding vacuum ( from where i get this information?)

-Vacuum pump type (

Centralized conveying system ■

Re: Help Pvc Grain Pneumatic Conveying System Vaccum

Dear mouadrabihsenhaji,

- Operational conveying rate with corresponding vacuum ( from where i get this information?)

The operational data from your

already installed PVC grain pneumatic conveying system (vaccum)

Best regards ■

Teus

Re: Help Pvc Grain Pneumatic Conveying System Vaccum

ok tank you sir ,

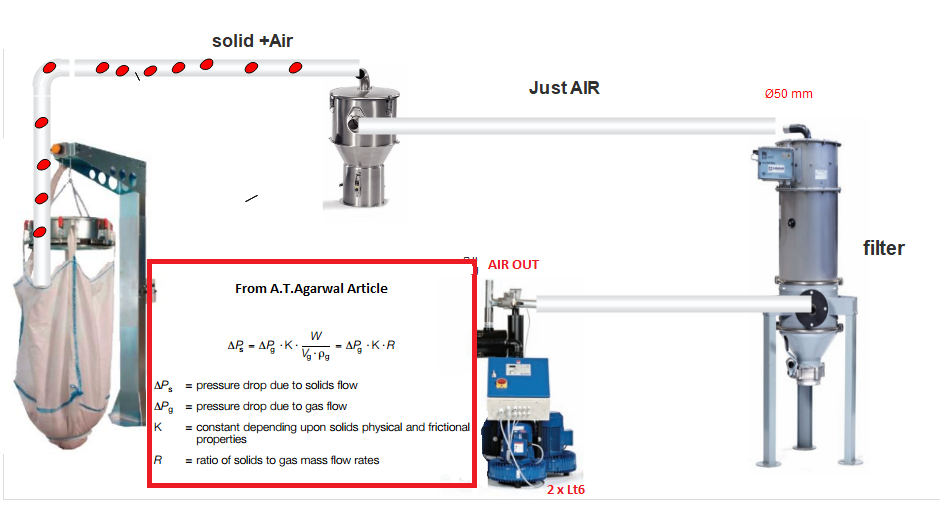

so what i need is not the result but the theorical steps that i should folow ....i read the article written by A.T. Agarwal i am not sure if is there any diffrent bettween blower installation (positive displacement ) and an aspiration systeme ( negative displacement) ( like in my case the pump aspirate the grain )

...tank you very much sir for your help ..and i am sorry for my english i am not a native speaker ■

Re: Help Pvc Grain Pneumatic Conveying System Vaccum

Dear mouadrabihsenhaji,

The theoretical steps are described in the article of Mr. Agarwal.

The first practical step is to calculate the existing installation and derive from that calculation the K-factor.

The second practical step is to calculate the modified installation with the derived K-factor and evaluate the new calculation results.

There is a difference between a pressure system and a vacuum system.

The difference lies not in the fundamental conveying physics, but in the behavior of the air mover.

Pressure system:

Compressor takes the air in from the ambient conditions and delivers an almost constant air mass flow in case of a Positive Displacement compressor.

Vacuum system:

Compressor takes the air in from the vacuum conditions and delivers a decreasing air mass flow with increasing vacuum, in case of a Positive Displacement compressor.

In case of a non-PD compressor, like a fan, you must follow the corresponding curves.

A compressor performs according to the intake conditions

Best regards

Teus ■

Teus

Re: Help Pvc Grain Pneumatic Conveying System Vaccum

i get confused

what i understand from you is that in my case i will not applicate the theoretical steps that are described in the article of Mr. Agarwal.

am i right ? ■

Re: Help Pvc Grain Pneumatic Conveying System Vaccum

Dear mouadrabihsenhaji,

what i understand from you is that in my case i will not applicate the theoretical steps that are described in the article of Mr. Agarwal.

The theoretical steps, you are referring to, are always valid.

When you apply those theoretical steps, you must account for the compressor behavior in the respective installation (pressure or vacuum)

Keep in mind that a compressor is the same as a vacuum pump.

Both machines compress gas from a low pressure to a high pressure.

(The same physical blower can be used for pneumatic pressure conveying as well as for pneumatic vacuum conveying)

A PD compressor has a constant displacement volume, which is not influenced by the pressure drop.

A fan has a flow rate displacement, which is depending on the pressure drop over the fan.

Best regards ■

Teus

Re: Help Pvc Grain Pneumatic Conveying System Vaccum

ok sir thanks..

how i can calculate the k-factor practically? ■

Re: Help Pvc Grain Pneumatic Conveying System Vaccum

Dear mouadrabihsenhaji,

By calculating your system and varying the K-Factor in that calculation until the calculation results match the operational data.

The derived K-factor is then the basis for calculating the modified installation.

Success ■

Teus

Re: Help Pvc Grain Pneumatic Conveying System Vaccum

sorry sir i dont get your point could you more explain ■

Re: Help Pvc Grain Pneumatic Conveying System Vaccum

that an example of the system that i want to study

https://www.youtube.com/watch?v=Qo1wrtPAQBo ■

Re: Help Pvc Grain Pneumatic Conveying System Vaccum

Dear mouadrabihsenhaji,

Going back to your original question:

I have a problem concern extanding piping installation of an already installed PVC grain pneumatic conveying system (vaccum) my question are :

Q1: how can i calculate the maximum distance (of piping) that my vaccum pump can handle to transport pvc grain from the pickup point to the hopper?

Q2:how can i calculate the pickup velocity of the pvc grain ?

if someone could give me thhe steps that i should follow to solve this problem?

Thanks

First:

Recalculate your existing installation according to the article written by A.T. Agarwal.

From that calculation, you know the corresponding K-Factor for your product.

Second:

Calculate your extended installation according to the article written by A.T. Agarwal.

In this calculation, use the corresponding K-Factor for your product, as calculated for the existing installation

What you then actually do is using the existing installation as a reference for the extended installation.

Take care

Teus ■

Teus

Re: Help Pvc Grain Pneumatic Conveying System Vaccum

in the article i found the equation attached in the picture

k=f(deltaPs,deltaPg,W,g)

if this equation that i should use to calculate K could you explain how i could practicly from the installation calculate the pressure drop due to solid flow and pressure drop due to gas flow and gas velocity ■

Re: Help Pvc Grain Pneumatic Conveying System Vaccum

Dear mouadrabihsenhaji,

Indeed, the formula, shown in the picture, is from Mr. Agarwal’s article.

You can kindly ask Mr. Agarwal on this forum for his article and the calculation spreadsheet for pressure- and vacuum conveying.

Success ■

Teus

Re: Help Pvc Grain Pneumatic Conveying System Vaccum

thank you sir for your help i really appreciate ■

Re: Help Pvc Grain Pneumatic Conveying System Vaccum

href="showthread.php?p=88773#post88773" rel="nofollow">

Indeed, the formula, shown in the picture, is from Mr. Agarwal’s article.

You can kindly ask Mr. Agarwal on this forum for his article and the calculation spreadsheet for pressure- and vacuum conveying.

Success

hello sir

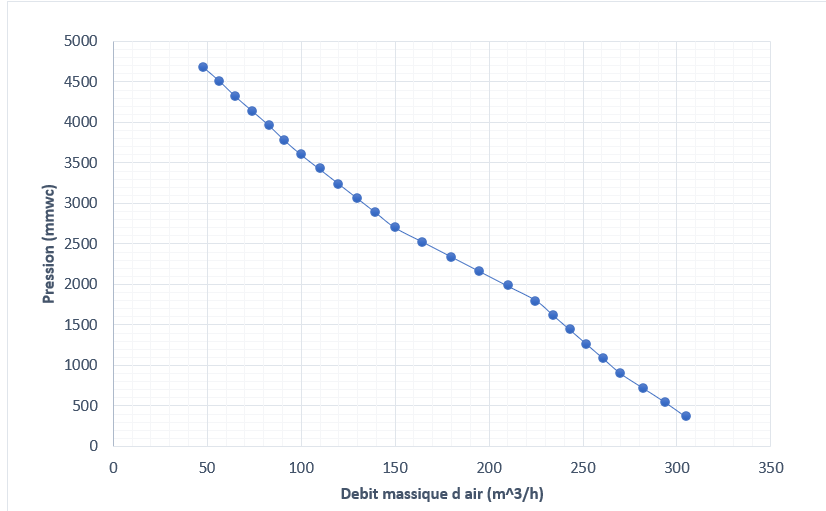

i done the calculation and i found pressure drop >4135 mmwc and air flow 124 m^3/hr

now i want to verify from the pump curve if my pump can handel this ....but i don t know how ? if you could explain to me how to use the graph

href="https://forum.bulk-online.com/attachment.php?attachmentid=45570&d=1523194600" title="Name: pump curve.PNGViews: 57Size: 31.4 KB">pump curve.PNG ■

Re: Help Pvc Grain Pneumatic Conveying System Vaccum

Dear mouadrabihsenhaji,

From the curve, I read:

4135 mmWC vacuum # 0.5865 bara

at 4135 mmWC vacuum, an airflow of 75 kg/hr

Assuming a temperature of 30 degrC

Volume=75/(1.293*0.5865*303/273) = 108 m3/hr

With a pipe diameter of 0.05 m:

v-begin = approx. 9 m/sec

v-end = approx. 15 m/sec

Success ■

Teus

Re: Help Pvc Grain Pneumatic Conveying System Vaccum

From the curve, I read:

4135 mmWC vacuum # 0.5865 bara

at 4135 mmWC vacuum, an airflow of 75 kg/hr

Assuming a temperature of 30 degrC

Volume=75/(1.293*0.5865*303/273) = 108 m3/hr

With a pipe diameter of 0.05 m:

v-begin = approx. 9 m/sec

v-end = approx. 15 m/sec

Success

thanks sir ...

... the air flow in the graph is m^3/hr not kg/hr

i dont understand what you done ....

Q1:why you calculate the volume ?

Q2:give the therotical equation that you use to calculcate volume ?

Q3: why you calculate v begin and v end ..and how? ■

Re: Help Pvc Grain Pneumatic Conveying System Vaccum

Dear mouadrabihsenhaji,

... the air flow in the graph is m^3/hr not kg/hr

You are correct.

I saw a straight curve and assumed kg/sec. My mistake.

Q1:why you calculate the volume ?

The volume is required to calculate the air velocity (not necessary to calculate anymore)

Q2:give the therotical equation that you use to calculcate volume ?

Volume = mass/density

Q3: why you calculate v begin and v end ..and how?

v-begin = Volume at begin / pipe area

v-end = Volume at end / pipe area

Have a nice day ■

Teus

HELP PVC grain pneumatic conveying system vaccum

hello ,

I have a problem concern extanding piping installation of an already installed PVC grain pneumatic conveying system (vaccum) my question are :

Q1: how can i calculate the maximum distance (of piping) that my vaccum pump can handle to transport pvc grain from the pickup point to the hopper?

Q2:how can i calculate the pickup velocity of the pvc grain ?

if someone could give me thhe steps that i should follow to solve this problem?

Thanks ■