Hang Up

Kindly explain how you expect to deliver the material to the filter baghouse.

Make your mind up whether pneumatic conveying does or does not work for this hypothetical material.

Blockages happen all the time even when the material has been sampled before committing to a design.

You need to be more specific with your situation. ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Re: Handling Of Cohesive Sticky Powder

The material is a bypass dust from a clinker kiln application. A bypass system is always used, when chlorine and sulphur amount in the hot gases are too high. Therefore, a portion of the hot gases are extracted and cooled down with fresh air. The chlorine condensates on the hot meal. Afterwards the gas is separated from solids in a bag house filter. If the chlorine content is too high it is very difficult to extract this material from the filter as well as the further handling (screw conveyors, screw pumps etc.) Most likely it will even stick to the bags. ■

Thank You

I am almost in the picture now.

If you talk to Ms Mohandes it might help. She can be found through the forums.

She has very recently asked about stack height from the filter baghouse and also, in another thread asked for a wet scrubber supplier.

I think you might have similar problems. A scrubber should not block and you could dewater with a suitable belt, drum or disc filter.

Sometimes it is better to make a clean sweep, so to speak. Downtime costs money. ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Handling Sticky Powders

Screw conveyors incorporating 'Lynflow' ribbon flights are used for handling cohesive and 'sticky' material, such as pastes and awkward materials, as their construction helps to keep material away from the centre shaft and avoids corners and adverse helical flight faces. ■

Recommendation For Handling Of Cohesive Sticky Powder

The only solution I know of would be to use a belt conveyor with a teflon or teflon coated (or a similar slippery material) belt. There would have to be a scraper across the belt located at the underside of the belt just inboard of the end so that anything that was still stuck to the belt as it moved around the end roller and started to go back under to return to the inlet would be knocked off. Check out this case study as well:

https://www.spiroflow.com/news/spiro...cky-situation/. Please feel free to respond if you have additional questions. ■

Non-Free Flowing Products, Discharger

If I would have a powder that has such a high cohesiveness and stickiness, so it wouldn’t even pass through a rotary valve or a screw conveyor of a bag filter, how will the possible measures look like in order to extract it from a filter? How can the transport over let’s say a length where a pneumatic transport is usually used? Pneumatic transport won’t work because of the stickiness. This material will simply stick and therefore block the pipe after time. Is there any known industry, which produces a powder with comparable powder characteristics with very bad handling properties?

Thanks!

-------------------------------------------------------------------------------------

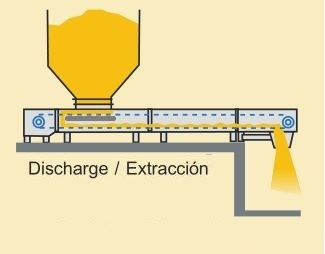

For (very) sticky cohesive materials you may consider this kind of bin discharger

or chain conveyor designed to discharge

But first it is necessary to make some bulk analysis to get the properties considering also that these may change if the product remains some time in a bin (30 minutes, 1 day, 2 days).

Please tell us how you managed your case, and add some pictures.

rgds

dak

T +1858 5644045

M +54911 53252311

E bulk.good.solutions@gmail.com ■

Re: Handling Of Cohesive Sticky Powder

Arnoldo

You are digging up old threads and hoping they will still be around. Maybe you should concentrate on the latest threads while promoting your products. Please check the thread dates before you post.

Better yet it might even be worth your while to advertise on this site.

Gary Blenkhorn

Moderator ■

Gary Blenkhorn

President - Bulk Handlng Technology Inc.

Email: garyblenkhorn@gmail.com

Linkedin Profile: http://www.linkedin.com/in/gary-blenkhorn-6286954b

Offering Conveyor Design Services, Conveyor Transfer Design Services and SolidWorks Design Services for equipment layouts.

Thanks

You are digging up old threads and hoping they will still be around. Maybe you should concentrate on the latest threads while promoting your products. Please check the thread dates before you post.

Better yet it might even be worth your while to advertise on this site.

Gary Blenkhorn

Moderator

Thank you, Garry.

But people also read this sites as an knowledge bank, because you can read many good answers and questions. By myself I learn here what the old experienced answers.

thanks again, and see you arround

arnoldo@bulkgood-solutions.com ■

Handling of cohesive sticky powder

Regarding the above mentioned topic, I got some questions and I would appreciate your help.

If I would have a powder that has such a high cohesiveness and stickiness, so it wouldn’t even pass through a rotary valve or a screw conveyor of a bag filter, how will the possible measures look like in order to extract it from a filter? How can the transport over let’s say a length where a pneumatic transport is usually used? Pneumatic transport won’t work because of the stickiness. This material will simply stick and therefore block the pipe after time. Is there any known industry, which produces a powder with comparable powder characteristics with very bad handling properties?

Thanks! ■