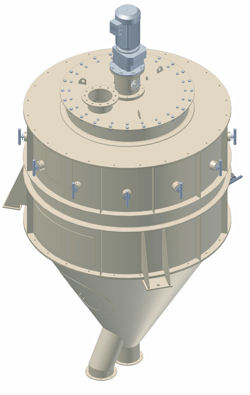

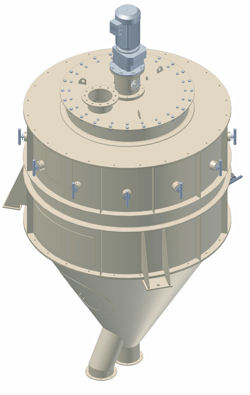

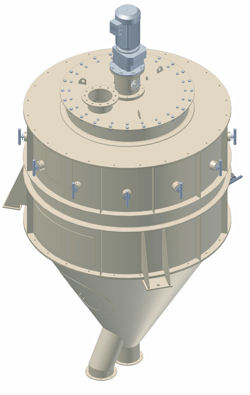

Sweco® Round Separators

Behind each Vibro-Energy Round Separator is the Sweco® legacy, synonymous with top quality equipment, innovative design, and exacting standards. Since 1942, when Sweco® patented the first vibratory separator to today's high yield Vibro-Energy Round Separators, Sweco® has continued our tradition of solutions and service.

Separate solids from liquids or segregate dry materials into various sizes. Particles as fine as 400 mesh (37 microns) can be screened, with up to 4 screen decks incorporated in one Sweco® separator. No special flooring or foundation is needed and less working floorspace is required. Simple and efficient design requires less horsepower. Other features include long screen life and ease with which screens may be changed.

The Sweco® Round Separator is a vibratory screening device that vibrates about its center of mass. Vibration is accomplished by eccentric weights on the upper and lower ends of the motion-generator shaft. Rotation of the top weight creates vibration in the horizontal plane, which causes material to move across the screen cloth to the periphery. The lower weight acts to tilt the machine, causing vibration in the vertical and tangential planes. The angle of lead given the lower weight with relation to the upper weight provides variable control of the spiral screening pattern. Speed and spiral pattern of material travel over the screen cloth can be set by the operator for maximum throughput and screening efficiency of any screenable product ... wet or dry ... heavy or light ... coarse or fine ... hot or cold.

View Video:

href="http://media.bulk-online.com/video/102/Sweco®-Vibro-Energy®-" target="blank">http://media.bulk-online.com/video/1...ibro-Energy®-

For more information, please visit:

href="https://edir.bulk-online.com/profile/1610-sweco.htm" target="blank">https://edir.bulk-online.com/profile/1610-sweco.htm

href="https://edir.bulk-online.com/profile/8357-sweco-europe.htm" target="blank">https://edir.bulk-online.com/profile...eco-europe.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=sweco+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

Sweco® Gyramax™

The Sweco® GyraMax™ Gyratory Sifter was specifically designed for sifting of dry particulate. With its multi-deck (up to five fractions) and high-volume capabilities, the GyraMax™ is ideal for various applications in many different industries including chemical, mining and minerals, stone, clay and glass, and plastics.

The GyraMax™ can increase your plant’s productivity by reducing the costs associated with routine maintenance and unscheduled repairs. That means fewer production outages and fewer instances of pulling employees away from other duties for unscheduled maintenance. It all adds up to less frustration, greater productivity and lower production costs.

Screen changes are quick and easy, even for multi-deck screeners. With the GyraMax™, you can change any screen at any level of the machine from either end without disturbing the other screens. Of course, if you want to change the screen through the top cover, you can do so. You won’t need overhead lifting gear to remove a heavy cover. The dust cover is constructed in sections that can easily be removed.

Screens are tensioned in place and can be easily re-tensioned as needed to return them to peak efficiency as they stretch. Screens are a one-piece hook design that eliminates the need for hundreds of attachment clips. With the GyraMax’s easy-access doors, it’s even possible to inspect for major problems without disturbing any of the screens or ball trays.

For more information, please visit:

https://edir.bulk-online.com/profile/1610-sweco.htm

https://edir.bulk-online.com/profile...eco-europe.htm

http://www.google.com/search?client=...UTF-8&oe=UTF-8 ■

■

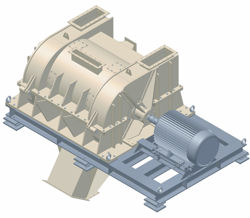

Multi-Motion (Mm) Rectangular Separator From Sweco®

Sweco® engineered the Multi-Motion Rectangular Separator specifically for liquid/solid separation in mind, which makes it ideal for processes that contain any effluent wastewater application. The MM is an excellent conveyor of solids and its screen changing ability is fast and easy, but its most impressive feature is its ability to adapt as solids’ characteristics change.

Combining the patented elliptical motion with linear motion technology, the MM is a revolutionary separator that delivers the benefits of two distinct motions. The groundbreaking design of the MM allows operators to use linear motion where heavy, high-volume solids are encountered. In these intervals, separators need to generate high g-forces to effectively move dense solids across the screens.

As conditions change, the MM can be adjusted “on the fly” without even turning off the machine. With the flip of a switch on the control box, motion is reconfigured from linear to elliptical mode. The solids encounter reduced g-forces and longer screen residence time — resulting in drier solids, longer screen life and reduced operating costs.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1610-sweco.htm" target="blank">https://edir.bulk-online.com/profile/1610-sweco.htm

href="https://edir.bulk-online.com/profile/8357-sweco-europe.htm" target="blank">https://edir.bulk-online.com/profile...eco-europe.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=sweco+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

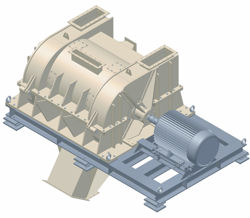

Universal Motion (Um) Rectangular Separator From Sweco®

The unique Universal Motion Rectangular Separator is the ultimate in flexibility of changing motions. The UM allows the user to precisely dial in the ideal motion for each application. Until the Sweco® UM innovation, completely different machines were necessary for such drastic motion changes. Round, balanced elliptical and linear motions are now simple field adjustments. A patented belt driven, indirect drive system provides all these motions, allowing optimum motion for every unique and sometimes changing application. In addition, the angle of motion, frequency, amplitudes and deck angles can also be adjusted to optimize any process.

Features available on other Sweco® Rectangular Separators are also available on the UM. These features include no-tools screen changing, the availability of pre-tensioned screens down to 400 mesh and the availability of several different size machines to accommodate customer capacity. Additionally, our UM models can be equipped with an optional vibrating spray system. Our sprays are designed to help keep the screen apertures clean and wash the oversize product off the screening surfaces.

The UM is ideal for use in many industries, including but not limited to food, chemicals and clay.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1610-sweco.htm" target="blank">https://edir.bulk-online.com/profile/1610-sweco.htm

href="https://edir.bulk-online.com/profile/8357-sweco-europe.htm" target="blank">https://edir.bulk-online.com/profile...eco-europe.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=sweco+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

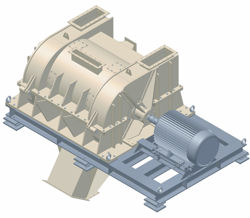

Round Motion Rectangular Separator From Sweco®

The gentle screening motion of the Round Motion Rectangular Separator is perfect for both wet and dry processes. The RM’s simple two bearing vibratory system, designed to run at 1200-2500 rpm, produces 2-6 g’s acceleration. Its effectiveness is maximized when inclined for dry screening or for horizontal wet scalping of slurries with a low percentage of oversized products. Good classification is also consistently achieved as the RM “tumbles and rolls” dry solids.

The standard round motion model is ideal for screening lighter weight materials and can be used throughout the chemical, food, pharmaceutical, plastic and mining industries. Common wet applications

include grit removal from fine clay slurries, titanium dioxide and dewatering of plastic pellets. Typical dry applications include the screening of feed meal, plastic resins and fine powders.

Created to meet specific processing requirements, the Sweco® RM Rectangular Separator has been tried, tested and proven over nearly two decades of intensive research, development and implementation in hundreds of successful start-ups throughout the process industries.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1610-sweco.htm" target="blank">https://edir.bulk-online.com/profile/1610-sweco.htm

href="https://edir.bulk-online.com/profile/8357-sweco-europe.htm" target="blank">https://edir.bulk-online.com/profile...eco-europe.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=sweco+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

V3 Dual Motion Rectangular Separator From Sweco®

Sweco ’s V3 was engineered primarily for wet processing of highly viscous material. Its dual motion, high-capacity sanitary design makes it ideal for use in such industries as kaolin clay, food, paper coating and ceramic slip just to name a few.

The V3 offers both elliptical motion and linear motion with just a flip of a control panel switch. Both motions provide benefits, but primarily linear motion offers superior solids conveyance, and elliptical

motion generates a much gentler motion and provides excellent screen life.

The V3 has very few moving parts that require little if any maintenance over the life of the machine. The interior surfaces have fewer cross-members that make the V3 easier to polish for sanitary applications requiring a crevice-free surface. Additionally, the screen basket can be polished to a mirror finish, and a clean-inplace system is available as an option.

The pre-tensioned screens are quick and easy to change. After unclamping and lifting the hinged top cover, any screen can simply be lifted out of the machine regardless of the screen’s location. The

screens are 100% sealed by Sweco® patented pneumatic seals. Unit patented drives produce up to 5.5 g’s for extra conveyance and motion generators are warranted for 36 months.

For more information, please visit:

https://edir.bulk-online.com/profile/1610-sweco.htm

https://edir.bulk-online.com/profile...eco-europe.htm

http://www.google.com/search?client=...UTF-8&oe=UTF-8 ■

Sweco® Rectangular Separators For The Paper Industry

Sweco® offers three sound options for a separation process in the Pulp & Paper Industry — the RM-CIP, UM-CIP and V3-CIP Rectangular Separators. With a paper coating application, processes require the removal of grit and fiber from the coating slurry. The Sweco® Paper Coating Rectangular Separators will filter the slurry, reducing the chances of scratches and other defects in your coated paper. Each model is available in a clean-in-place design to virtually eliminate screen blinding and the accumulation of hard coating on internal surfaces.

The RM-CIP utilizes a high-speed circular motion ideal for high throughput screening. Additionally the circular motion places less stress on the screen cloth, which yields longer life for your screens.

The V3-CIP can be tailored to your process to produce either elliptical or linear motion at the flip of a switch. The high g-force produced by the patented drive allows for better conveyance and higher throughputs. The CIP features and modular design make the V3-CIP very easy to clean between

production runs, and the machine can be polished to eliminate crevices where material tends to get trapped. The hinged cover makes changing screens easier than any other rectangular separator design.

The UM-CIP can be customized to your process to produce either round, elliptical or linear motion through a series of mechanical adjustments. This model produces more amplitude than any of

Sweco ’s other Rectangular Separators, producing a better conveyance to maximize the machine’s throughput. Furthermore, in addition to its three-panel model, the UM-CIP comes in a four-panel design that increases the active screen surface by 33%.

With years of application experience and product knowledge in the Pulp & Paper Industry, Sweco® can offer a quality product and technical expertise for your process.

For more information, please visit:

https://edir.bulk-online.com/profile/1610-sweco.htm

https://edir.bulk-online.com/profile...eco-europe.htm

http://www.google.com/search?client=...UTF-8&oe=UTF-8 ■

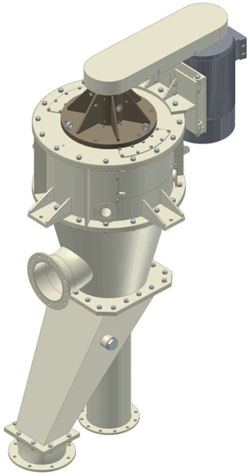

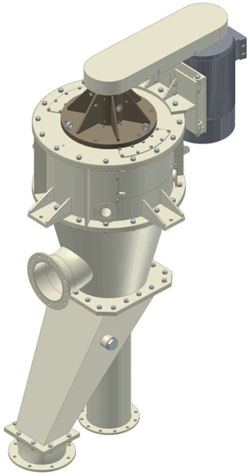

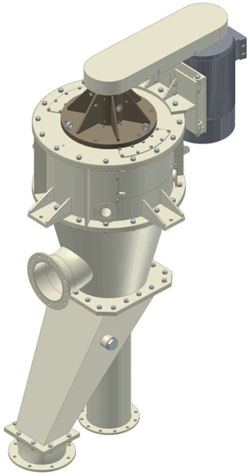

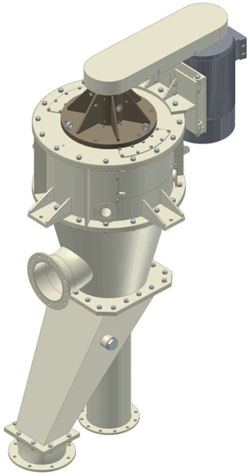

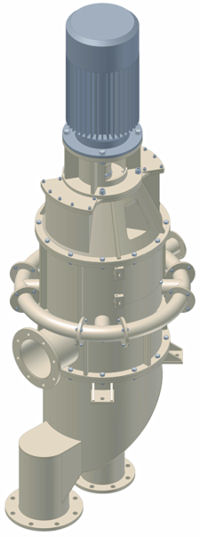

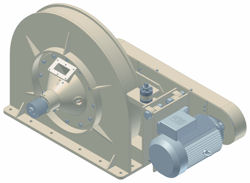

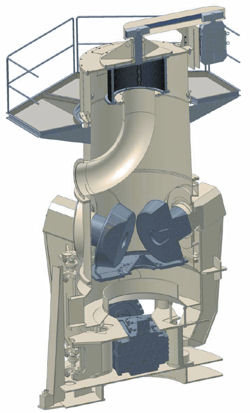

Alpha Air Classifiers

The Ecutec ALPHA Classifier belongs to the family of turbo classifiers with turbulent air flow, also called

centrifugal classifiers. Their purpose is to achieve the best yield at very low specific energy consumption.

Their solid construction reflects Ecutec’s philosophy of design for long operation lifetimes.

Ecutec will provide not only the classifier for your process, but, if necessary, a complete turnkey system including feeding, air handling, material handling and controls. Be assured that Ecutec ALPHA classifiers

are used by world leaders in the field of minerals, chemical and other processing applications. The ALPHA Classifier is ideal for use with cosmetics, fertilizers, pigments, minerals, basic chemical products and many other materials.

The ALPHA can be supplied with a ceramic classifier wheel and the body itself can be lined with ceramics or polyurethane for wear protection when processing abrasive materials or to prevent iron contamination. If required, the classifier rotor and the body can be constructed in

stainless steel. Other options are available upon request.

The Ecutec ALPHA Series Turbo Classifiers. Simply one more innovation available from Sweco®.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1610-sweco.htm" target="blank">https://edir.bulk-online.com/profile/1610-sweco.htm

href="https://edir.bulk-online.com/profile/8357-sweco-europe.htm" target="blank">https://edir.bulk-online.com/profile...eco-europe.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=sweco+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

href="https://edir.bulk-online.com/profile/2275-ecutec-barcelona.htm" target="blank">https://edir.bulk-online.com/profile...-barcelona.htm

Attachments

■

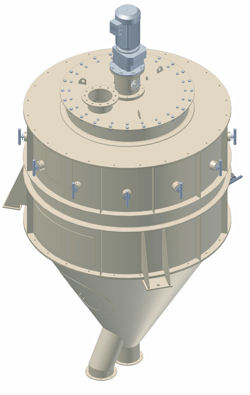

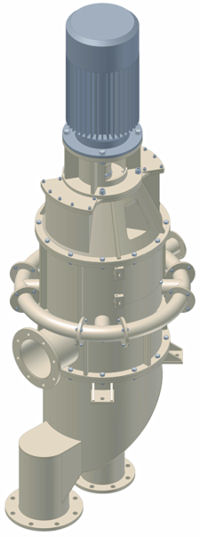

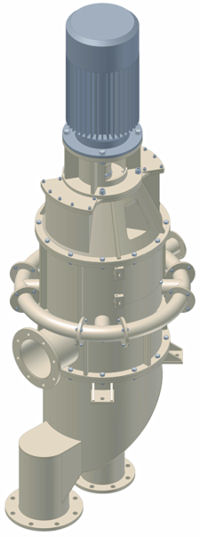

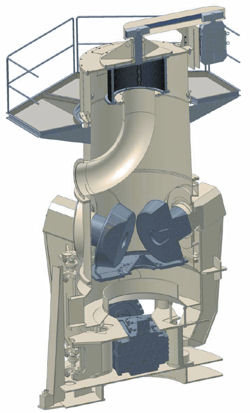

Uls Air Classifiers

The Ecutec ULS series of air classifiers belong to the family of internal draught or unit classifiers.

Design:

•Ecutec ULS classifiers do not require external de-dusting, a fanset or any other auxiliary equipment.

•The self contained process generated through internal fans and a distributor plate enables this classifier type to achieve fine particle classification. These particles are swirled to the upper part of the machine and are transported to the outer cone while the coarse particles fall down into the inner cone.

•Available with polyurethane and ceramic lining as well as with special abrasive resistant steels.

Applications and Processes:

•The extremely robust design, low maintenance and multiple possibilities of regulating the internal air flow enable this classifier to be adjusted to the necessities of many applications.

•Suitable for a variety of dry materials especially for minerals with a maximum in-feed-size of 3mm

•De-dusting and classifying of fine powders from d98 < 45 microns – 300 microns with a feed rate up to 80 t/h, depending on the material.

•Applications vary between de-dusting before fine screening, production of defined final products and products with a designed particle size distribution.

Features and Benefits:

•Improves fine screening

•High throughputs

•Easy adjustment of cut points

•Minimal maintenance due to robust design

•Low specific energy consumption

For more information, please visit:

href="https://edir.bulk-online.com/profile/1610-sweco.htm" target="blank">https://edir.bulk-online.com/profile/1610-sweco.htm

href="https://edir.bulk-online.com/profile/8357-sweco-europe.htm" target="blank">https://edir.bulk-online.com/profile...eco-europe.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=sweco+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

href="https://edir.bulk-online.com/profile/2275-ecutec-barcelona.htm" target="blank">https://edir.bulk-online.com/profile...-barcelona.htm

Attachments

■

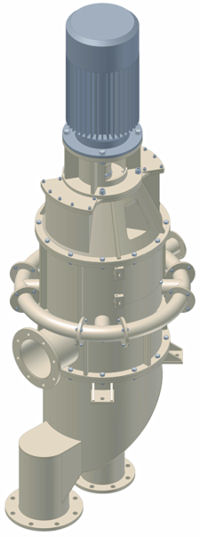

Nea Air Classifiers

The NEA series of air classifiers have been developed specifically for ultra-fine products with high added value. These high performance classifiers are ideal for the production of toner and other similar products due to their high separation sharpness.

Design:

•Ecutec's NEA turbo air classifiers produce fine powders by separating a defined grain size from a fed turbulent air flow by creating a “virtual” mesh with a fast rotating classifier wheel. The suction force of the air stream normally produced by a ventilator forces the fine particles though the classifier wheel into a filter where the particles are separated from the air stream. The coarse particles fall down and are washed out again through new incoming air and feed material.

•The direct drive of the classifier wheel guarantees the highest possible tip speeds allowing the NEA to produce very fine products.

Applications and Processes:

•Suitable for a variety of dry powders especially for high-added value products like abrasives, metals, toners and pharmaceuticals.

•Solid ceramic rotors available in alumina, silicone carbide and silicone nitrate make the NEA perfect for abrasives and non-ferrous production.

•Ideal for pharmaceutical batch processes.

Features and Benefits:

•Cut-points starting from d98 < 2 microns up to 50 microns and from lab-size to 24 t/h feed

•Housing lined with ceramic or polyurethane

•Stainless steel construction available

•Innovative axial blades for improved recovery

•Direct Transmission

•Minimal maintenance due to robust design

•Low specific energy consumption

For more information, please visit:

href="https://edir.bulk-online.com/profile/1610-sweco.htm" target="blank">https://edir.bulk-online.com/profile/1610-sweco.htm

href="https://edir.bulk-online.com/profile/8357-sweco-europe.htm" target="blank">https://edir.bulk-online.com/profile...eco-europe.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=sweco+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

href="https://edir.bulk-online.com/profile/2275-ecutec-barcelona.htm" target="blank">https://edir.bulk-online.com/profile...-barcelona.htm

Attachments

■

Tfs Air Classifier

High fineness, very sharp cut points, high yield and low specific energy consumption are just some of the benefits you’ll receive from ECUTEC’s TFS air classifiers. These horizontal turbo classifiers have been designed to produce ultra-fine products down to d98 < 2 microns on an industrial scale at a highly competitive energy consumption compared to alternative process technologies.

Ecutec engineers have optimized the dynamics of the air flow and mechanical resistance of the moving parts in this classifier. Additionally, the use of hybrid rotors with a high diameter/length ratio and a construction of sophisticated composite materials have enabled the TFS to reach tip speeds of more than 160 m/s.

The TFS creates a virtual mesh with its fast rotating horizontal classifier wheel. The suction force of the air stream normally produced by a ventilator forces the fine particles though the vertical wheel into a filter where the particles are separated from the air stream. The coarse particles fall down and are then returned to the process. An optional double suction placed at the end of the classifier wheel minimizes the pressure drop and saves energy costs, while the fine fraction quality is guaranteed with a dynamic sealing system.

TFS air classifiers are designed for the ultra-fine classification of industrial minerals such as calcite, chalk, feldspar, talc, and graphite, just to name a few. Additionally, due to their high precision of separation, TFS classifiers are also well suited for toner and other similar products.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1610-sweco.htm" target="blank">https://edir.bulk-online.com/profile/1610-sweco.htm

href="https://edir.bulk-online.com/profile/8357-sweco-europe.htm" target="blank">https://edir.bulk-online.com/profile...eco-europe.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=sweco+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

href="https://edir.bulk-online.com/profile/2275-ecutec-barcelona.htm" target="blank">https://edir.bulk-online.com/profile...-barcelona.htm

Attachments

■

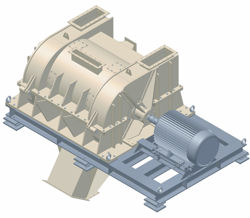

Smw Pin Mill

On Ecutec SMW pin mills both sets of pin discs are driven, either in the same or in opposite directions.

Design:

•Feed material is introduced in between the two pin discs, which depending on the application are either contra rotating or fixed.

•The airflow through the mill helps guarantee the grinding quality, material temperature and pneumatic transport.

Applications and Processes:

•For fine grinding and de-agglomeration applications.

•With contra-rotating pin discs the resulting tip speed is over 200 m/s which enables the grinding of soft to medium hard minerals (up to 3 Mohs) to a high fineness.

•Suitable for cryogenic grinding and coating applications.

Features and Benefits:

•Two independently working pin discs

•Relative speed more than 240 m/s

•Easy access allows for simple and fast pin replacement

•Minimal maintenance due to robust and reliable design

For more information, please visit:

href="https://edir.bulk-online.com/profile/1610-sweco.htm" target="blank">https://edir.bulk-online.com/profile/1610-sweco.htm

href="https://edir.bulk-online.com/profile/8357-sweco-europe.htm" target="blank">https://edir.bulk-online.com/profile...eco-europe.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=sweco+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

href="https://edir.bulk-online.com/profile/2275-ecutec-barcelona.htm" target="blank">https://edir.bulk-online.com/profile...-barcelona.htm

Attachments

■

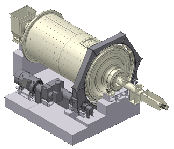

Kgm Ball Mill

Design:

•KGM ball mills have an extremely robust and reliable design engineered by Ecutec.

Applications and Processes:

•KGM ball mills are used for fine and ultra-fine grinding of all types of minerals and ores.

Features and Benefits:

•Grinding efficiency through engineering know-how

•Options for abrasives are available

•Improved product quality through special grinding media

For more information, please visit:

href="https://edir.bulk-online.com/profile/1610-sweco.htm" target="blank">https://edir.bulk-online.com/profile/1610-sweco.htm

href="https://edir.bulk-online.com/profile/8357-sweco-europe.htm" target="blank">https://edir.bulk-online.com/profile...eco-europe.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=sweco+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

href="https://edir.bulk-online.com/profile/2275-ecutec-barcelona.htm" target="blank">https://edir.bulk-online.com/profile...-barcelona.htm

Attachments

■

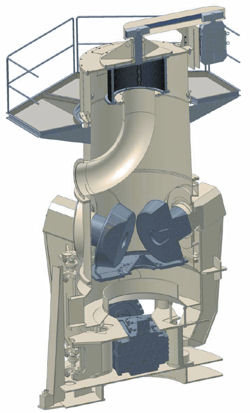

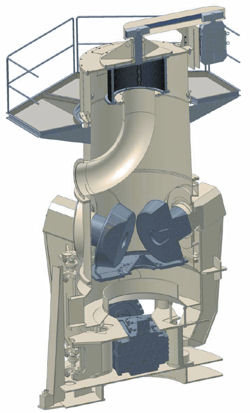

Vertical Roller Mill (Vrm)

The VRM is a revolutionary mill which represents a significant step forward in the quest for more efficient fine grinding of soft to medium-hard materials.

Design:

•The basic concept of the VRM is based on the combination of a high quality mill body and a highly efficient ECUTEC classifier. The classifiers used with the VRM are the TC or the ALPHA.

•The mill body is designed with either 2 or 3 rollers and can work with standard gear boxes. Due to an innovative and integrated bearing system of the roller table, the VRM does not need any reinforcement on the gearbox itself. This reduces delivery time and makes maintenance easy. Additionally, the milling force is no longer transmitted to any foundation, but directly relied to the roller arms.

•An additional access platform around the classifiers makes maintenance and operation convenient.

Applications:

The VRM is the solution for fine grinding and classification of a wide variety of materials including:

•Calcium Carbonate

•Dolomite

•Talc

•Bentonite

•Barites

•Petroleum Coke

•Calcium Oxide (Burnt Lime)

•Gypsum and many more. . .

Features and Benefits:

•Integrated bearing system

•Closed milling force circuit

•Short delivery time

•Sharp cut point

•Easy maintenance and operation

•Low energy consumption

For more information, please visit:

href="https://edir.bulk-online.com/profile/1610-sweco.htm" target="blank">https://edir.bulk-online.com/profile/1610-sweco.htm

href="https://edir.bulk-online.com/profile/8357-sweco-europe.htm" target="blank">https://edir.bulk-online.com/profile...eco-europe.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=sweco+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

href="https://edir.bulk-online.com/profile/2275-ecutec-barcelona.htm" target="blank">https://edir.bulk-online.com/profile...-barcelona.htm

Attachments

■

Sweco® Grinding Mills

Sweco® Vibro-Energy® Grinding Mills are the most versatile line of mills available for fast, low-cost particle size reduction to sub-micron range. Vibro-Energy grinding action achieves higher output per input horsepower and precise control of size and distribution. Product contamination from media and lining wear is virtually eliminated. Maintenance costs are low because of few moving parts and replaceable linings made of abrasion-resistant metal, ceramic or elastomers.

The Sweco Vibro-Energy Mill's unique vibratory motion, coupled with the use of cylindrical media, allows a dense packing of the media bed assuring maximum media surface contact and minimum void area when operated under a low energy condition. Feed materials as large as 300 microns can be reduced to sub-micron sizes.

In the high energy configuration, feed materials as large as twelve inch agglomerates have been successfully milled and solid particles of a half inch are being reduced to a d50 of 5 microns.

The low energy condition is reserved for wet milling whereas the higher energy mode can be used either wet or dry.

View Video of our Grinding Mill Motion:

href="http://media.bulk-online.com/video/101/Sweco®-Vibro-Energy®-Grinding-Mills-" target="blank">http://media.bulk-online.com/video/1...rinding-Mills-

For more information, please visit:

href="https://edir.bulk-online.com/profile/1610-sweco.htm" target="blank">https://edir.bulk-online.com/profile/1610-sweco.htm

href="https://edir.bulk-online.com/profile/8357-sweco-europe.htm" target="blank">https://edir.bulk-online.com/profile...eco-europe.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=sweco+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

Sweco® Finishing Mills

The three-dimensional Vibro-Energy® Motion of Sweco® finishing mills subjects parts and media to a consistent high frequency tilting movement as they travel in a helical/orbital path around the chamber. The resulting compressive scrubbing action cleans and also removes burrs, round sharp corners, and smooths out surface impressions. Because vertical/horizontal amplitudes and the rate of vibration are completely adjustable, your finishing requirements can be handled quickly and efficiently.

Sweco® Batch Finishing Mills are ideally suited for use with external separating systems, manual parts unloading and for processes that have no media and the entire load can be easily discharged out the bottom door.

Sweco® Long Radius Finishing Mills provide a convenient means for separating parts from media. The DLR series provides both batch automatic and continuous finishing. Internal parts and media separation mills utilize a swing blade and a fixed separation screen mounted within the unit. The long-radius toroidal chamber design has excellent discharge characteristics.

Sweco® Spiral Finishing Mills or SLR series mills make available a long-radius spiral finishing chamber featuring fully-automatic parts/media separation utilizing an air-operated discharge gate and a fixed separating screen. Even unusual shapes and sizes discharge easily. These units are suitable for a wide range of finishing applications (including ball burnishing and media finishing) both batch and continuous. One of the most essential features on these mills is the long retention time of parts for single pass applications.

The Sweco® Removable Center Column Finishing Mill offers all the advantages of Sweco 's unique Vibro-Energy finishing plus design features for easier operation and more efficiency. The chamber, which incorporates a removable center column, allows you to run larger than normal parts in the mill. Adjustments in finishing action are easily made by varying lead angle and motor weight settings. No tools are required for such adjustments. Sound levels have been reduced by the use of special materials and new fabrication techniques.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1610-sweco.htm" target="blank">https://edir.bulk-online.com/profile/1610-sweco.htm

href="https://edir.bulk-online.com/profile/8357-sweco-europe.htm" target="blank">https://edir.bulk-online.com/profile...eco-europe.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=sweco+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

href="http://www.google.com/search?num=50&hl=de&client=safari&rls=de-de&q=ecutec+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?num=50&...btnG=Suche&lr=

Attachments

■

Sweco® High Performance Decanting Centrifuges

The Sweco® CD500 & CD600 Decanting Centrifuges boast infinite speed adjustability of main bowl drive and backdrive (differential). Utilizing variable frequency drives on all motors allows low amperage start-ups and eliminates troublesome sheave changes. Stainless Steel wetted parts, tungston carbide hard facing on bowl and scroll, as well as superior gearbox construction make the CD500 & CD600 durable and rugged centrifuges.

•High Volume – solids removal while processing up to 400+ GPM of feed (rated with water)

•Fully Variable Speed Main and Back Drive – allows maximum control of solids dryness and throughput

•Duplex A890 bowl & scroll with 304 stainless steel compartment and feed pipe are corrosion resistant and provide long service life

•Optional variable speed pump – A variable controller allows the operator to adjust the pump to a desired speed allowing feed rate to be adjusted to improve solids control efficiency

•Tungsten carbide tiled conveyor with improved feed zone minimizes chemical consumption and improves cake dryness

•Dynamically balanced to run at high speed for extended periods with greater efficiency, minimizing maintenance and downtime

The drive system is mounted in a control cabinet and consists of electrical variable speed controls for the main-drive, back-drive, positive displacement feed pump, bearing temperature, differential speed, and a digital hour meter readout. The control box houses all centrifuge's control functions with digital gauges located on the control box or remote mounted.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1610-sweco.htm" target="blank">https://edir.bulk-online.com/profile/1610-sweco.htm

href="https://edir.bulk-online.com/profile/8357-sweco-europe.htm" target="blank">https://edir.bulk-online.com/profile...eco-europe.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=sweco+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

href="http://www.google.com/search?num=50&hl=de&client=safari&rls=de-de&q=ecutec+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?num=50&...btnG=Suche&lr=

Attachments

■

Sweco® 414 And 518 Centrifuges

The Sweco® 414 and 518 Centrifuges are the premier high-speed, decanting centrifuges for fluids cleaning and solids removal and product recovery applications. Ruggedly built for industrial service, they are especially effective in environmentally sensitive areas. They deliver high recovery rates and efficient solids separation to significantly reduce disposal costs or reclaim valuable material from process streams. The Sweco 414 and 518 Centrifuges are precision-balanced for smooth operation over long periods at high RPM speeds, generating extremely high G-forces.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1610-sweco.htm" target="blank">https://edir.bulk-online.com/profile/1610-sweco.htm

href="https://edir.bulk-online.com/profile/8357-sweco-europe.htm" target="blank">https://edir.bulk-online.com/profile...eco-europe.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=sweco+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

href="http://www.google.com/search?num=50&hl=de&client=safari&rls=de-de&q=ecutec+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?num=50&...btnG=Suche&lr=

Attachments

■

Sweco® Pharmasep™

The Sweco ® PharmASep™ is a fully contained Vibro-Energy Filter/Dryer suitable for aseptic processes in the pharmaceutical industry. With a design that eliminates gaps, crevices and hidden areas, the PharmASep™ proves valuable to those processes handling potent and/or toxic substances where containment is an important issue. The PharmASep™, with clean-in-place and steam-in-place capabilities, enables users to properly clean the machine without the need to disassemble and re-assemble, reducing downtime and ultimately increasing productivity. In the case of wet sieving, the PharmASep™ can dewater the product on the screen, apply vacuum, dry and discharge the dried product, eliminating the necessity for separate vacuum drying.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1610-sweco.htm" target="blank">https://edir.bulk-online.com/profile/1610-sweco.htm

href="https://edir.bulk-online.com/profile/8357-sweco-europe.htm" target="blank">https://edir.bulk-online.com/profile...eco-europe.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=sweco+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

href="https://edir.bulk-online.com/profile/2275-ecutec-barcelona.htm" target="blank">https://edir.bulk-online.com/profile...-barcelona.htm

Attachments

■

Sweco® Aftermarket Products

Authentic Sweco Aftermarket Products (ASAP), are made to tough, precise standards. Careful materials selection, rigorous quality control and unsurpassed manufacturing methods assure correct fit, superior wear resistance and long service life for everything from clamp rings to covers. ASAP parts and inventory options assure you of "panic-free" processing.

Sweco offers the industry’s widest variety of screen solutions to meet any separation challenge. In addition to our round screen offerings, Sweco also manufactures Rectangular and White Water Filter screens plus custom manufactured screens to meet any requirements.

The latest in a long line of technologically advanced products from Sweco® is the Sweco® Fusion™ Screen. Fusion™ screens have been designed to eliminate the use of adhesive, epoxy or silicone in screen manufacturing. The mesh is fused directly into the patented polymer construction tension ring. The repeatability of the robot construction assures precise tensioning, lower tolerances and smaller deviations in the screens. The robot construction also allows for rapid turnaround time so you get your screens faster.

Other Sweco® aftermarket products include motors, covers, springs, spout connectors and frames. Additionally we offer Sweco’s patented Smart-Lock™ Force wheels, Self Cleaning Kits, No-Tools Center Tie Downs and the Sweco TechLube™, an automatic grease relubricator.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1610-sweco.htm" target="blank">https://edir.bulk-online.com/profile/1610-sweco.htm

href="https://edir.bulk-online.com/profile/8357-sweco-europe.htm" target="blank">https://edir.bulk-online.com/profile...eco-europe.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=sweco+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

href="https://edir.bulk-online.com/profile/2275-ecutec-barcelona.htm" target="blank">https://edir.bulk-online.com/profile...-barcelona.htm

Attachments

■

Sweco® White Water Filter

Sweco's White Water Filter is the ultimate in white water recycling. It uses centrifugal force to produce shower quality water at a capacity of 4000 gallons per minute. It provides high flow rate, fine mesh centrifugal screening to remove all particles larger than screen mesh opening with no dependence on differences in specific gravity. It is ideal for effluent and water recycle streams for large plants. Units are available that remove suspended solids down to 500 mesh (25 microns).

The White Water Filter is constructed of 316 or 304 stainless steel with all stainless steel internals. Its non-plugging design needs almost no operating attention and is insensitive to normal process fluctuations. Additionally, the White Water Filter provides cost savings in several areas: energy, water, fiber, chemicals and wastewater treatment.

Applications:

• Paper machine shower water preparation

• Vacuum pump seal water filtration

• Washer shower water filter

• Thickener shower water filter

• Save-all shower water filter

• Incoming fresh water filter

Attachments

■

Sweco® Sono-Wave

The Sono-Wave fully digital ultrasonic system promotes improved screen excitation throughout the screen surface with more even energy distribution and also features adjustable amplitude and frequency sweep. The generator is available in 100w and 200w versions and can drive two screens simultaneously eliminating the need to use a second generator in two deck applications. The ultrasonic converter mounts outside of the separator. With no cable or electrical components inside the separator, the unit can be configured to meet Atex Zone 20standards.

Attachments

■

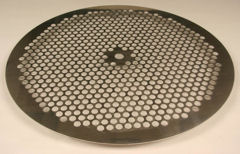

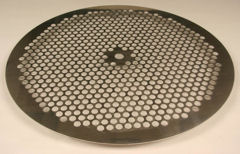

Quiet Clean™ Perforated Plate

Perforated plates are used in conjunction with sliders and/or balls to dislodge near-size particles or fibers and improve screening efficiency. The Quiet Clean multi-laminate perforated plate is an excellent method of controlling excess noise. Compared to standard metal perforated plate designs, it reduces noise by up to 14%.

The Quiet Clean is FDA Approved for food and pharmaceutical products and it is available in sizes up through 48 inch.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1610-sweco.htm" target="blank">https://edir.bulk-online.com/profile/1610-sweco.htm

href="https://edir.bulk-online.com/profile/8357-sweco-europe.htm" target="blank">https://edir.bulk-online.com/profile...eco-europe.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=sweco+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

href="https://edir.bulk-online.com/profile/2275-ecutec-barcelona.htm" target="blank">https://edir.bulk-online.com/profile...-barcelona.htm

View these Videos:

href="http://media.bulk-online.com/video/101/Sweco®-Vibro-Energy®-Grinding-Mills-" target="blank">http://media.bulk-online.com/video/1...rinding-Mills-

href="http://media.bulk-online.com/video/102/Sweco®-Vibro-Energy®-Round-Separators" target="blank">http://media.bulk-online.com/video/1...und-Separators

Attachments

■

Sweco®

SWECO

Sweco, a business unit of M-I L.L.C., is a leading manufacturer of customized industrial separation equipment. We manufacture round, rectangular and pharmaceutical separators plus several lines of complimentary separation products, centrifuges, grinding mills, finishing mills and a wide variety of aftermarket screens and parts. Additionally, Sweco recently acquired Ecutec Barcelona S.L., a company that specializes in classifying, coating and grinding of fine and ultra-fine powders.

Sweco has 13 manufacturing facilities and over 100 service offices surrounding the globe. Headquartered in Florence, KY, USA, Sweco also maintains manufacturing facilities in Macon, GA, Tulsa, OK, Belgium, Scotland, Italy, Poland, Spain, India, China and Singapore, a joint-venture in Mexico, and a licensee in Australia. With this type of global commitment, you can be assured that Sweco will provide you with the best service in the industry . . . no matter where you are located.

For more information, please visit:

https://edir.bulk-online.com/profile/1610-sweco.htm

https://edir.bulk-online.com/profile...eco-europe.htm

http://www.google.com/search?client=...UTF-8&oe=UTF-8

View our videos:

http://media.bulk-online.com/video/1...rinding-Mills-

http://media.bulk-online.com/video/1...ibro-Energy®- ■