Excess Moisture In Filter Cake

======================================================

======================================================

Greetings and salutations,

About your vacuum filters which brand are they?

This leads me to ask several questions of you.

How many square feet of fabric does the drum filter have?

How much tension on the fabric? if its not tight it will work poorly.

What is the operating speed RPM?

What has changed recently that makes you want to change?

a. Sometimes maintenance done by inexperienced staff causes major problems for the machinery.

b. Are you using a different brand less expensive brand of blower to replace the OEM blower?, the quality of the machining effects the blower performance.

c. Have you properly adjusted the flow regulator/relief valve for your actual altitude?- this is something that must be done properly with math and altitiude charts from the Delaval milk house vacuum guage and testing kit.

1. How often do you change the fabric?

a. What is the thread count of the current fabric?

b. Is the fabric properly tensioned on the drum filter?

c. Are you diligent about repairing the tears in the fabric?

d. How often do you check the scraper that rmoves the filter cake ?

e. Have you examined the scrapers? It may simply be that they need adjusting or replacing.

3. Are you using a less expensive fiter fabric from another supplier?

4. how ofter do you shut down to perform maintenance on the vacuum filter?

a. do you inspect and clean the suction ports that the filter fabric rides over to check for restrictions/ dirt / mold build up / pin hole leaks in the suction lines across the drum filter suction area?

b. Is there an air gap betwwen the fabric and the suction lines-if there is that is a no no.

5. What type of maintenance do you perform if any?

a. How often do you clean the water chamber to reduce any chance of back ups and low flow?

b. How often do you check the chain drive for tension-if used.

c. How often do you grease the bearings? / have you changed them recently? a bad bearing install is a big problem

d. what is the conditon of the chain drives and sprockets if used? are they properly tensioned?

If a chain drive is used -

1,The vacuum drum filter operates in one direction and there can be no slack in the

upper drive chain, whre as some slack is allowed in the lower chain only.

a. Is the drive chain in the water chamber or outside?

b. how often is it oiled or is it in an oil bath chain case?

d. A bad chain with worn rollers will have slippage effects on the sprockets and affect the true energy delivery

where it is not a balanced continuos movement.

6.What type of vacuum generator is used?

a. Regenerative centrifugal blower

b. Rotary lobe positive displacement blower- which is the most efficient of all types?

c. High speed standard fans to create suction through filter cloth

7. About the blower if used, etc.

a. Where is the air inlet for the blower? Is there free unfiltered air flow entering the intake of the blower?-if so that is a big no no.

b.How often are you changing the air filters- the tattle tale air filter restriction indicators cannot be trusted to work properly.

c. Do you use water injection to cool the intake air stream to make it more efficient by making it cooler and in the process more dense making it more energy efficient and productive-more suction due to denser air flowing through the blower?

d. Do you have a "Delaval milkhouse vacuum testing guage kit" to check the efficiency of the blower under load?

1. The guages on the blower air stream are not an efficient method/not trustworthy in regard to checking Hg or PSIG.

e. How often are the air filters changed- by operating hours-if known, or by days of operation.

f. How often are the drive belts examined for wear or loose belts?

g. How often do you change the belts?

h. Do you use a v belt tension guage to tighten the belts properly?

i. Do you check to be sure the V belt pulley is square/true in relation to the electric

motor drive pulley?.

j. How oftern do you check the oil level or grease the bearings?

k. How often do you check the electric motor for efficiency / resistance?

l. The blowers may simply need to be replaced with new ones as they may be worn,

and the blower lobes may be very worn affecting amount of suction energy.

j. The blower lobes create suction or pressure gradients by the very close clearances of the lobes

to the side plates of the blower housing and the center housing of the blower.

===================================================================================

===================================================================================

A simple change can have drastic effects on any machinery.

Any vacuum drum filter has a narrow, very narrow area of suction

to do its job period and you have to realize this fact.

If you have increased the amount of concentrate and flow water

to dewater with your existing vacuum drum filters THAT is the

obvious answer and the solution would be add another vacuum

filter to the fleet.

If a higher denier fabric is available for the drum filter that would be

the easy fix for your situation.

A slower replacement reduction gear box will work as well.

Its fine to ask but we need all the information from you.

The problem is you have not provided all the information I/we require for this problem

lzaharis ■

Reduction In Moisture Content

Dear lzaharis,

Thanks for your attention to my question. I am looking to provide additional information of this filter.

My regards,

VVCPE ■

Minimum Moisture Content

what is the minimum moisture content practically can be achieved with vacuum drum filter for iron ore concentrate?

if we would like to have 8% moisture can we use vacuum drum filter? ■

Vaccum Filter

Vacuum Filter

99% of the problem will decide the last 1%. the drier the taconite is prior to the vacuum filter the better of course. ■

Moisture Content

Dear Tafakor,

This vacuum drum filter was supposed to achieve at 9% moisture content, but as I mentioned, it produces more than 10%. ■

Re: Reduction Of High Moisture Content

Dear friends,

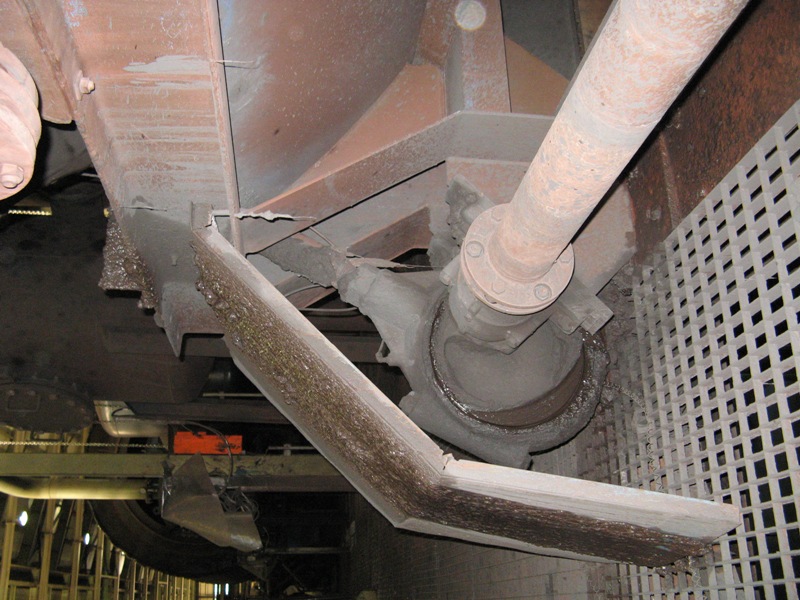

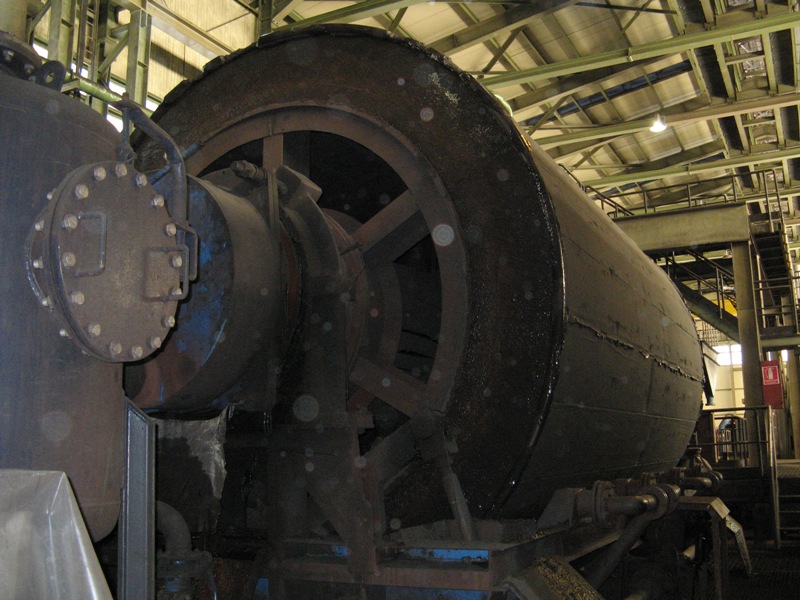

Some of the pictures from this filter are available here.

regards

VVCPE

Attachments

■

Moisture Content Reduction

Greetings to Mr. lzaharis,

1- you mean that drum filter is not suitable for this application(8%moisture content)?

2- what do you mean about the pre drier? if we use drier before drum filter, we can reach this level of moisture content? type of drier?

3- what is your suggestion if we would like to reduce moisture content of iron ore concentrate from 12% to 8%? ■

Re: Reduction Of High Moisture Content

Greetings and salutations,

Your vacuum filter is doing its job and the filter cake is falling away as it should.

Does your iron ore have a lot of clay in it?

The pictures you have provided are very good with detail in illustrating the flow of material.

I would do several things:

1. check all the vacuum plumbing to see if you have leaks- a lit cigarette (or a hand held smoke generator)

around the sealing surfaces/seals of the vacuum connections will tell you if you have a vacuum leak quickly.

Check the central duct and the drum interior if possible to see if any mud or slime build up exisits as this will

have an effect on pressure gradient generation.

--------------------------------------------------------------------------------------------------------------------------------------------

If this is the case, time should be used to steam clean the interior of the drum and central channel would provide

much relief if it is possible to access the interior.

======================================================================

======================================================================

======================================================================

2 Reduce volume of the feed water slurry into the recieving tank for the vacuum filter.

This would allow more Hg per square foot of filter cloth to remve more moisture per square foot of filter cloth

Second:

Some drum driers use a diamtomacious earth top coat on the drum which aids as an additional filter to solve

problems with sticky solids and uneaven flows of material and provides a dry cake.

1. I would see what I need to do to slow the drum rotation down to reduce amount of mud being pulled upon

the filter fabric at one time and find out if it is possible to do this by contacting the manufacturer of the drum

drier or thier representative in your area.

I would also see how much a diatomaceos earth top coat would cost to be placed on your drum as this is the best way

to solve a problem like this.

If you could provide more pictures showing the drive unit for the vacuum filter that would be a big help to the forum and me.

If you reduced the volume of slurry entering in the recieving tank it can only help you and reduce the loading of the filter fabric.

About the drum drive it self:

Is it rotated with a reduction gear box delivering rotary energy through a drive sprocket to a sprocket on the drum

What is the chain size? is it double row chain? Is the chain tight? how long has the chain been in use?

Is the drum drive a hydraulic drive with a chain driven by a hydraulic motor?

Or is the drum drive a direct drive with a radial piston hydraulic motor secured to the mounting/support frame of the drum? Are there 2 motors?

Or is the drum drive an electric motor/direct gearbox drive with a shaft drive to the drum?

==================================================================================================== ==================================================================================================== =================================================================================================

you may have a build up of solids inside the drum and not know it.

The use of a diatomaceos earth drum liner on the drums circumference

may solve this problem entirely as it has proven to give excellent results

in other difficult to dry materials in many instances.

lzaharis ■

Supplier

Dear designer,

I went through net to find a supplier of steam drier. I found a chinese one which was of too low capacity. I provided some picture of the the drum filter and would appreciate your efforts in this case. Please see Izaharis quotation on the forum to follow the disscusion.

My regards,

VVCPE ■

More Information

Dear Izaharis,

I am trying to provide some additional pictures.

Thank you in advance

VVCPE ■

Filter Aid

Dear Izaharis,

I don't know if we can use a diatomite filter aid to reduce 2-3% moisture content or it is just for clarification?

My regards,

VVCPE ■

Vacuum Filter

Additional Picture

Dear Izaharis,

Attached, provided two additional pictures of drum filter.

Regards,

VVCPE

href="https://forum.bulk-online.com/attachment.php?attachmentid=17731&d=1262275224" id="attachment17731" rel="Lightbox60839" target="blank">■

Drum Vacuum Filter

Happy New Year,

You have lots of room there to add a diatomite liner for the drum filter. I can forward to you the name of the company that does this and at least one installation example for you to look at as well.

leon ■

Reduction of High Moisture Content

Dear friends,

we have iron ore concentrate filter cake with high moisture content that was produced by vacuum drum filter. We want to reduce the moisture content by modification of our drum filters. Would you please help me.

Regards,

VVCPE ■